Networked flow production line timing production system

A production system and production line technology, applied in the general control system, control/adjustment system, comprehensive factory control, etc., can solve the problems of slowing down the overall production line efficiency, difficulty in finding bottleneck positions, and unknown working time, etc., so as to make it easy to find , production line scheduling optimization, and the effect of improving production line capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0019] refer to figure 1 with figure 2 , propose an embodiment of a networked flow production line timing production system of the present invention:

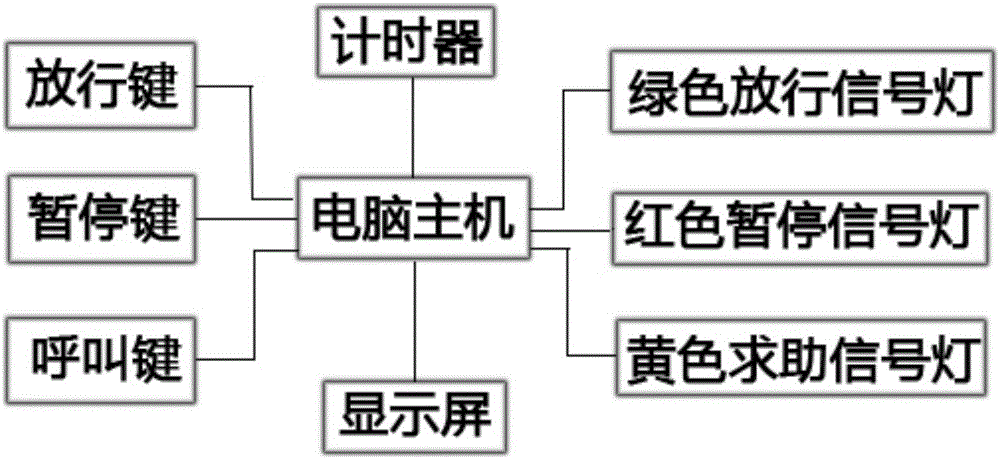

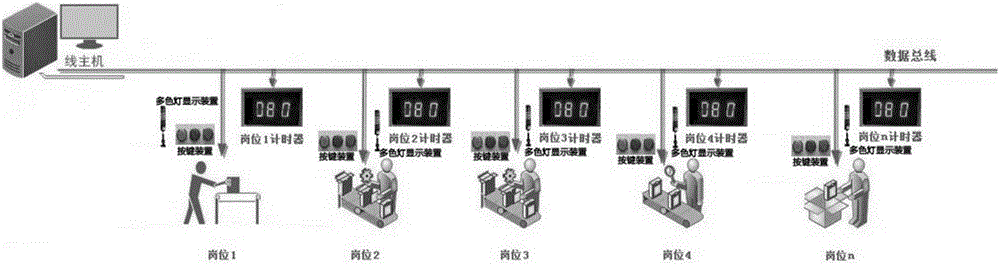

[0020] A timing production system for a networked flow production line, comprising a host computer with built-in control software, a display screen connected to the host computer, a timer set on each post for timing operation of the post, and a timer set on each post The button device used to control the production line of the corresponding post to suspend or continue to run, and the multi-color light display device set on each post to display the production status of the current post. The timer, the button device and the multi-color light display device are connected with the host computer through the RS485 bus.

[0021] The timer has a built-in buzzer for the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com