Soybean milk machine with efficient pulverization function

A high-efficiency crushing and soybean milk machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of difficulty in obtaining dregs-free taste soy milk and reduced crushing efficiency, and achieve good effect, good dregs-free crushing, and improved crushing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

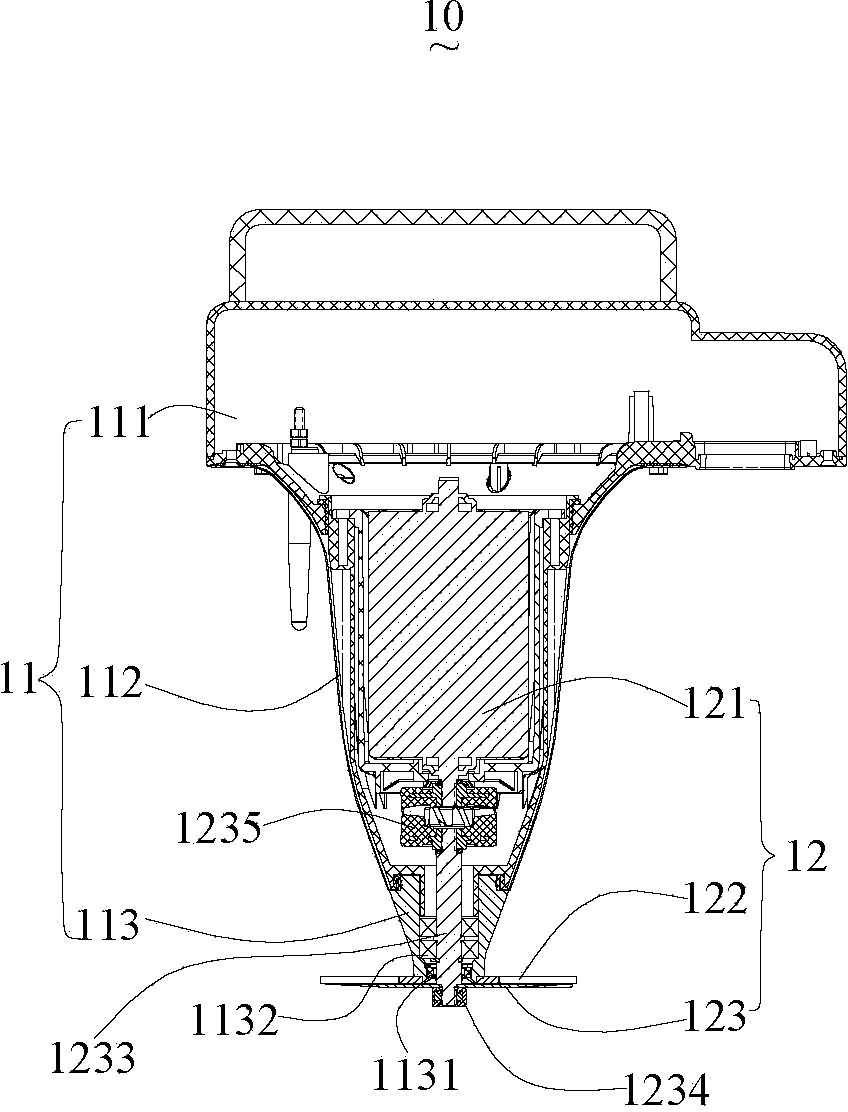

[0037] Please also refer to figure 1 and figure 2 The high-efficiency pulverizing soybean milk machine 10 includes a machine head 11 , a cup body (not shown in the figure) and a crushing device 12 , the machine head 11 is buckled on the cup body, and the crushing device 12 is installed on the machine head 11 .

[0038] In this embodiment, the machine head 11 includes an upper cover 111, a lower cover 112 and a connecting body 113, the upper cover 111 and the lower cover 112 are fastened together to form a cavity, and the connecting body 113 is fixed on the lower end of the lower cover 112, The connecting body 113 is provided with a bearing seat and a shaft sealing ring 1131 , and a bearing 1132 is fixed in the bearing seat.

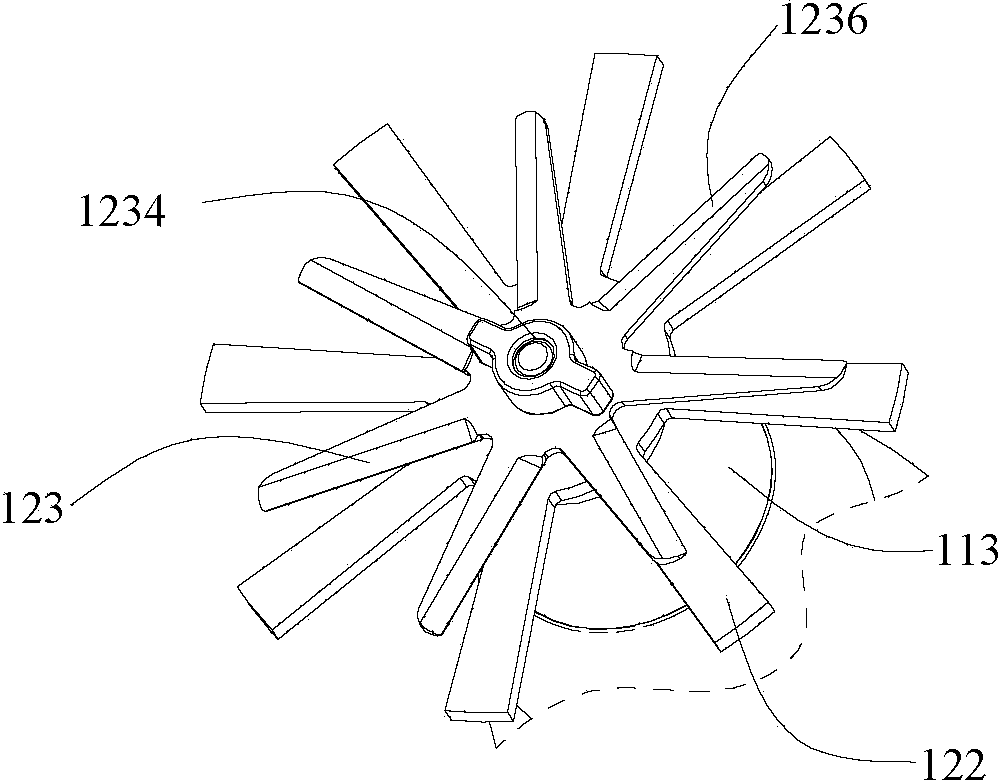

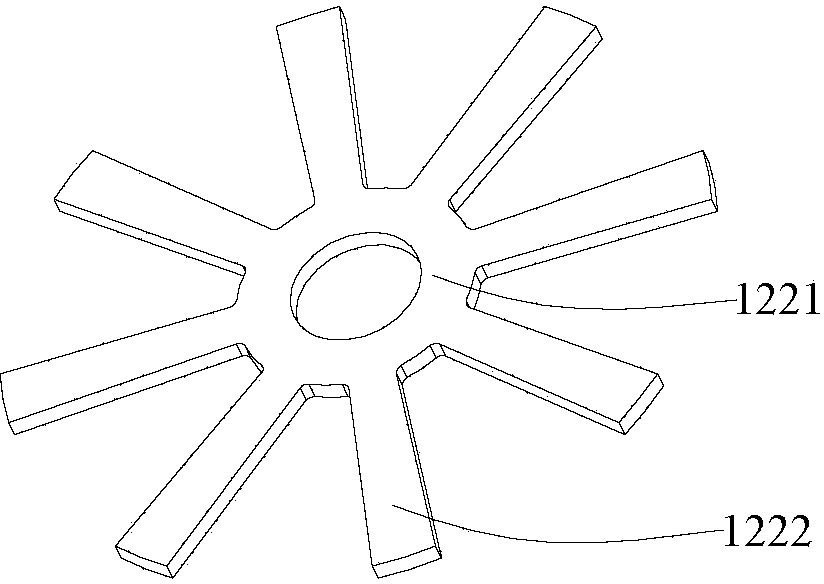

[0039] The crushing device 12 includes a motor 121, a fixed knife 122 and a moving knife 123. The motor 121 is fixedly installed in the cavity formed by the fastening of the upper cover 111 and the lower cover 112. The fixed knife 122 is fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com