Coal slime sludge and raw coal mixed fuel crushing device

A technology of mixing fuel and crushing device, applied in grain processing and other directions, can solve the problems of reducing the repeated crushing and crushing efficiency of the crusher, and achieve the effect of improving the repeated crushing effect, improving the crushing efficiency and improving the crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

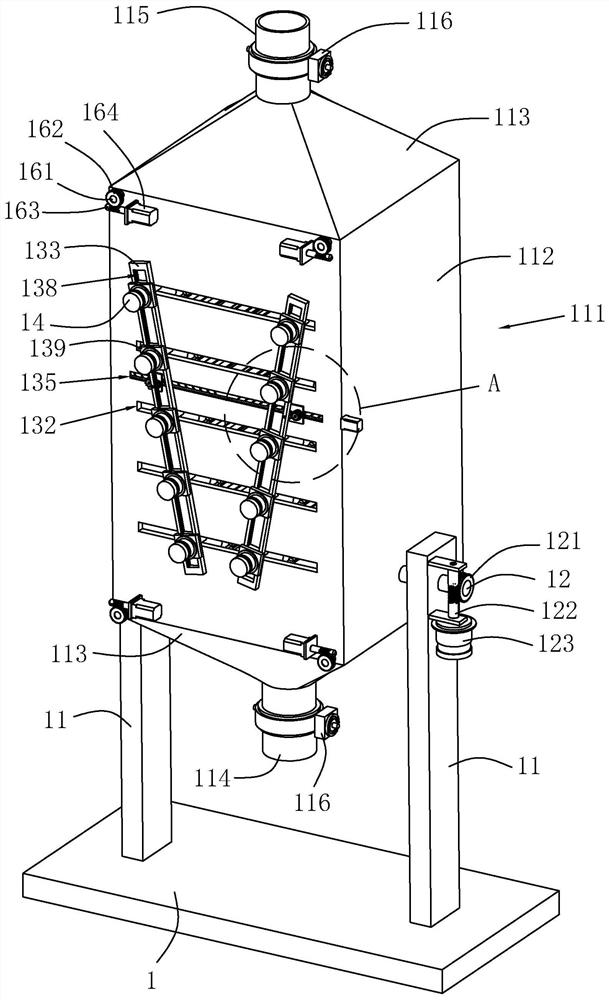

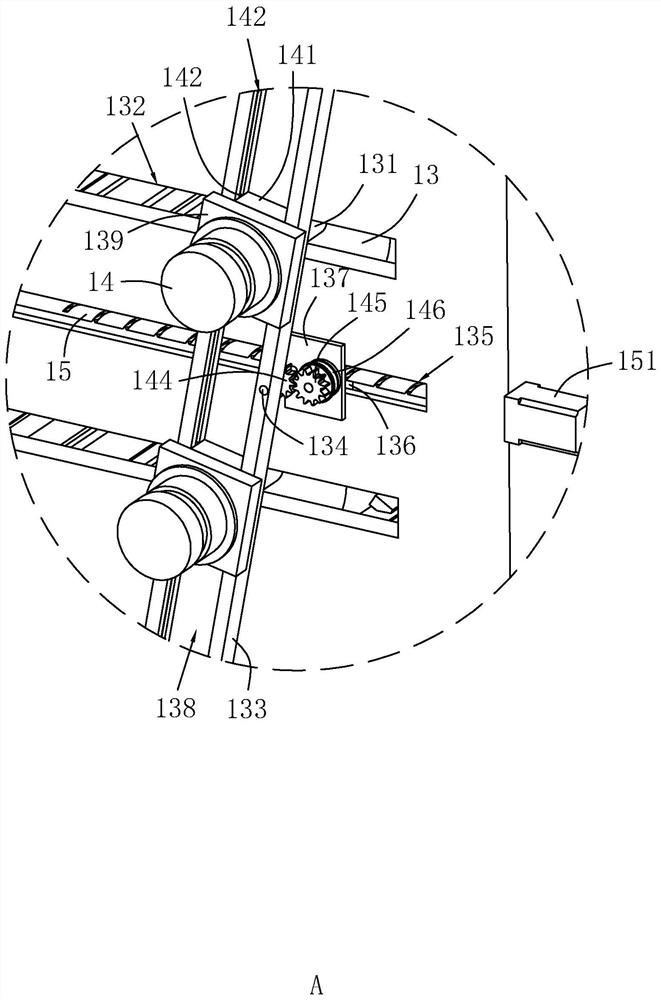

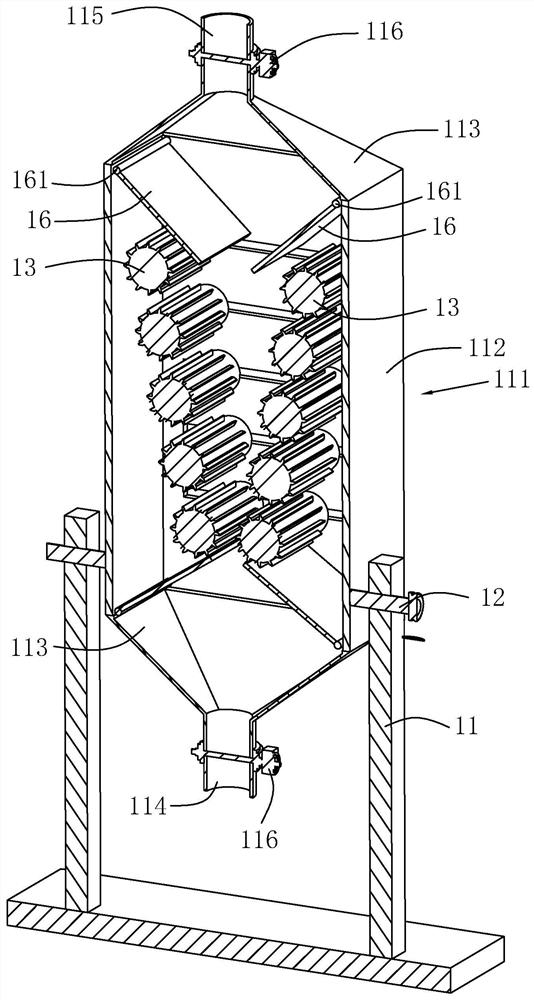

[0033] The following is attached Figure 1-3 The application is described in further detail.

[0034] The embodiment of the application discloses a coal slime sludge and raw coal mixed fuel crushing device. refer to figure 1 , a coal sludge and raw coal mixed fuel crushing device, including a bottom plate 1, a rod body 11 is arranged on the bottom plate 1 and on both sides of the bottom plate 1, and a crusher body 111 is arranged between the rod bodies 11 on both sides. The body 111 includes The vertical section 112 and the reducing section 113 arranged at both ends of the vertical section 112, the cross-sectional area of the reducing section 113 on both sides gradually decreases toward the direction close to the vertical section 112, and the surface of the body 111 facing the bottom plate 1 is provided with Outlet pipe 114, feed pipe 115 is provided on the surface of body 111 away from bottom plate 1, and switch 116 is arranged on feed pipe 115 and discharge pipe 114, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com