Clamp for thermal resistance test of SMD packaged semiconductor device

A test fixture and semiconductor technology, which is applied in the direction of single semiconductor device testing, measuring device casing, etc., can solve the problems of electrode short circuit and inability to test, and achieve the effects of fast measurement, good electrical contact and heat transfer, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

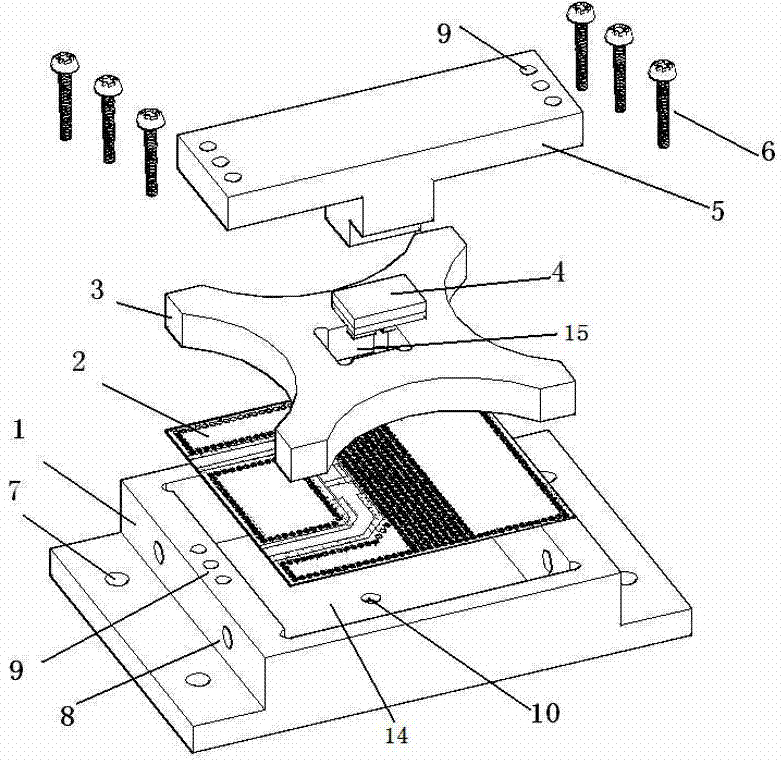

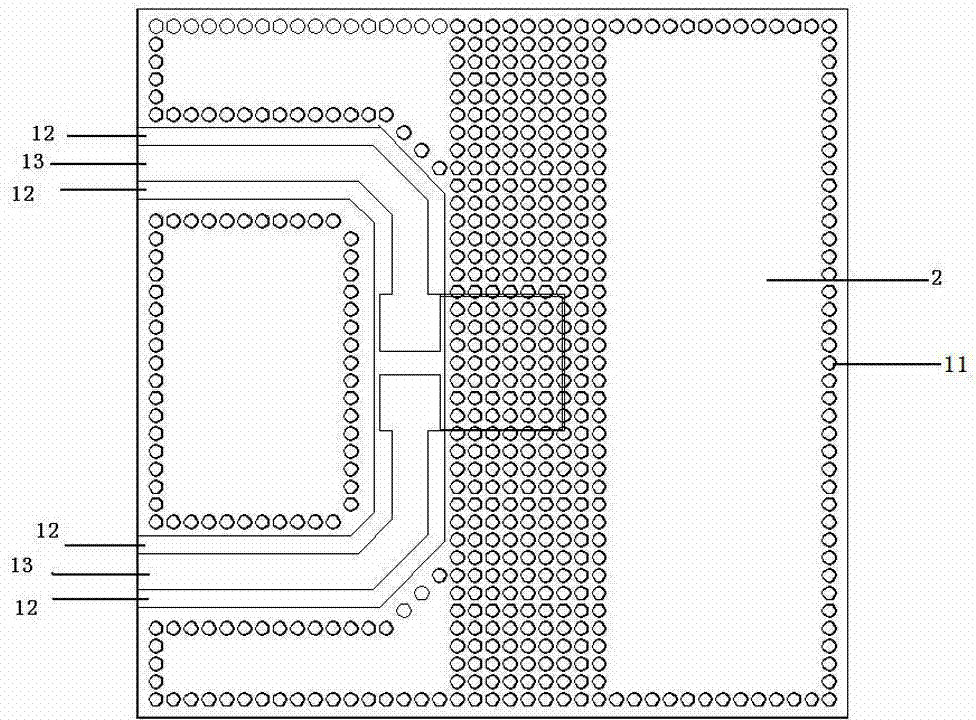

[0022] Such as figure 1 As shown, a jig for testing thermal resistance of an SMD packaged semiconductor device includes a metal base 1 , a PCB circuit board 2 , an insulating positioning block 3 and a pressing block 5 . The metal base 1 is made of copper, and the metal base 1 is provided with a groove 14, and the thickness of the bottom of the groove 14 is 1 mm. The PCB circuit board 2 is placed in the groove 14, and the conductive silver paste or conductive paper is coated between the PCB circuit board 2 and the groove 14. The PCB circuit board 2 is a nickel-plated gold circuit board, and the thickness of the PCB circuit board 2 is 0.5mm, the nickel-plated gold circuit board has good thermal conductivity, which is beneficial to the heat transfer between the tested SMD device 4 and the constant temperature platform. The PCB circuit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com