Heat transfer plate for a plate-and-shell heat exchanger

A heat transfer plate and heat exchanger technology, applied in the field of heat transfer plates, can solve the problem that the combination of stress resistance and heat transfer capacity of plate and shell heat exchangers is not optimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

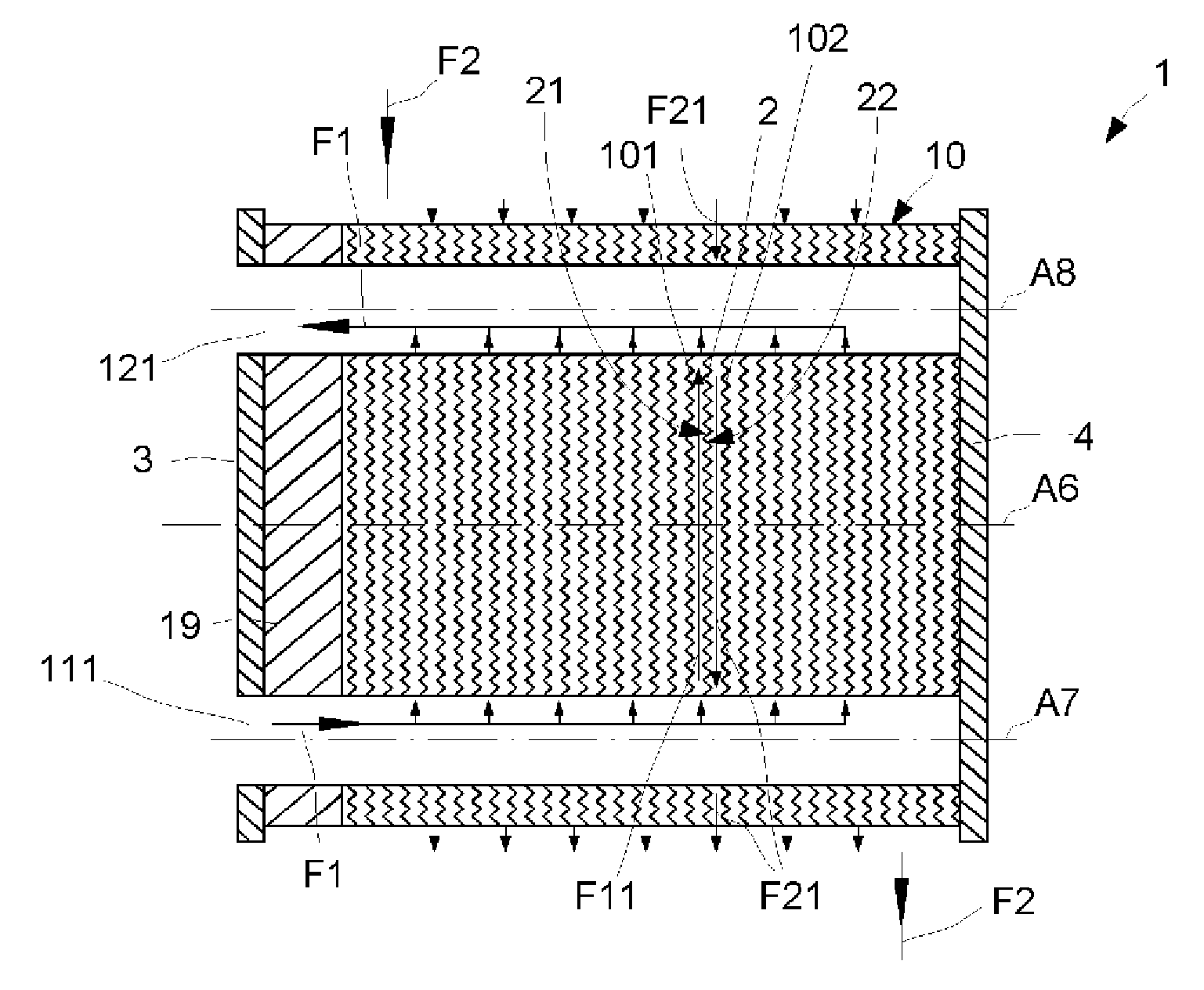

[0030] refer to figure 1 , shows a plate and shell heat exchanger 1 . The heat exchanger 1 comprises a housing 5 , a first end plate 3 and a second end plate 4 . The housing 5 is circular in this example, but other shapes, such as oval, are conceivable. The plate and shell heat exchanger 1 has four ports 11 , 12 , 13 , 14 which, depending on its use and configuration, constitute the inlet or outlet ports of the heat exchanger 1 . In the illustrated example, port 11 is the inlet port and port 12 is the outlet port for the first fluid flow F1, while port 13 is the inlet port and port 14 is the outlet port for the second fluid flow F2.

[0031] The inlet port 11 and the outlet port 12 of the first fluid flow F1 are arranged at the first end plate 3 relatively close to the outer edge of the first end plate 3 and at opposite sides of the center of the first end plate 3 . The inlet port 13 and the outlet port 14 of the second fluid flow F2 are arranged on the housing 5 at opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com