Method for measuring coefficient of heat transfer of solidification interface under action of alternating magnetic field

A technology of solidification interface and heat transfer coefficient, which is applied in the field of metal solidification heat transfer measurement, can solve problems such as measurement error, harmonic interference of thermocouple data acquisition, unsuitable measurement, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention is described in detail below in conjunction with accompanying drawing:

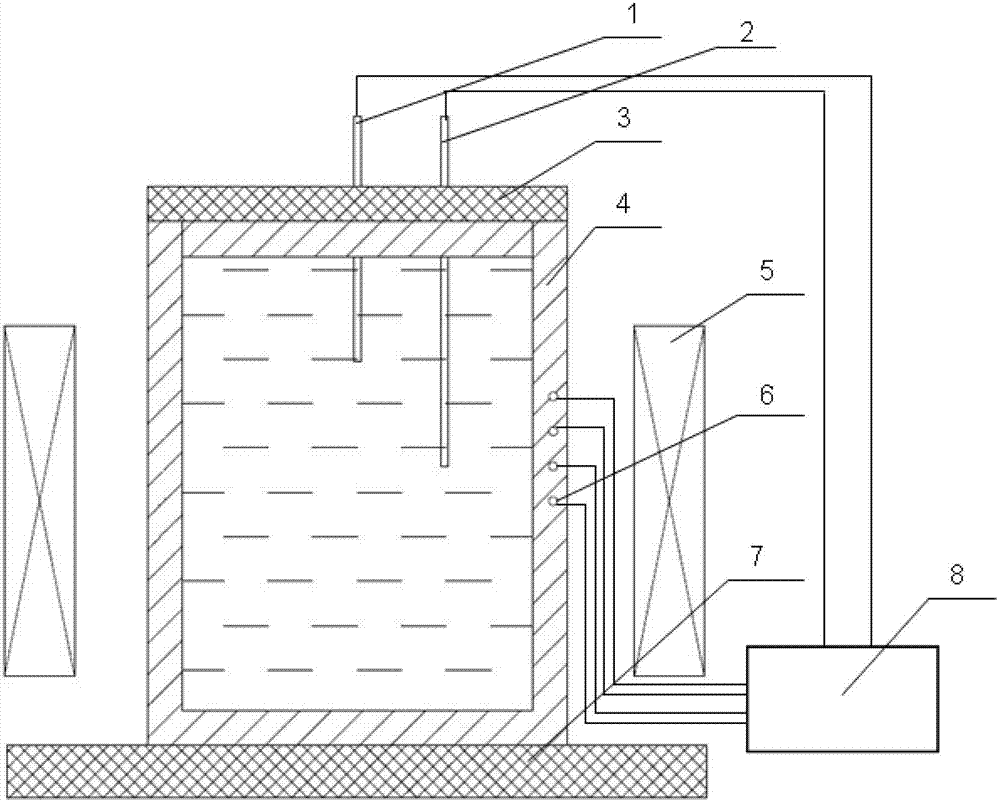

[0018] See figure 1 , the described device for measuring the interface heat transfer coefficient of a metal solidification process under the action of an alternating magnetic field includes a first melt temperature measuring thermocouple 1, a second melt temperature measuring thermocouple 2, an upper surface insulation material 3, a cylinder Forming mold 4, induction coil 5, mold temperature measuring thermocouple 6, lower surface insulation material 7, data acquisition and calculation system 8.

[0019] The cylindrical mold 4 is placed on the lower surface heat insulating material 7, the cylindrical mold 4 covers the upper surface heat insulating material 3, the thickness of the upper surface heat insulating material 3 and the lower surface heat insulating material 7 are both 10-50mm, and the cylindrical mold 4 is placed on In the inner area of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com