Combined Fluid-Air Evaporator And Novel Switching Concept For A Heat Pump In A Ventilating Apparatus

a technology of fluid-air evaporator and heat pump, which is applied in the direction of energy-efficient heating/cooling, space heating and ventilation details, domestic heating details, etc., can solve the problems of reducing the service life of the compressor, increasing the complexity of the cooling loop, and increasing the cost of the equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

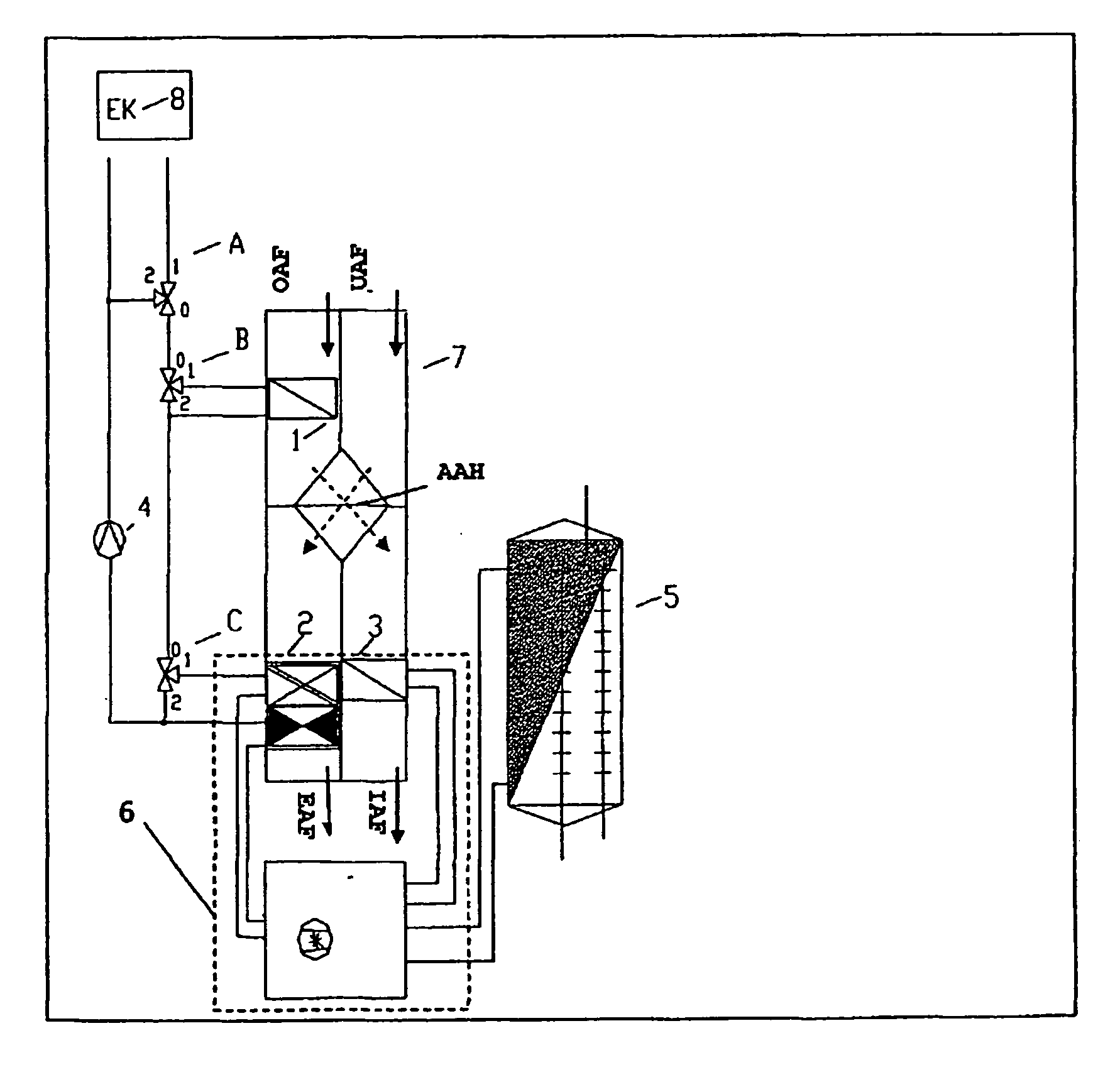

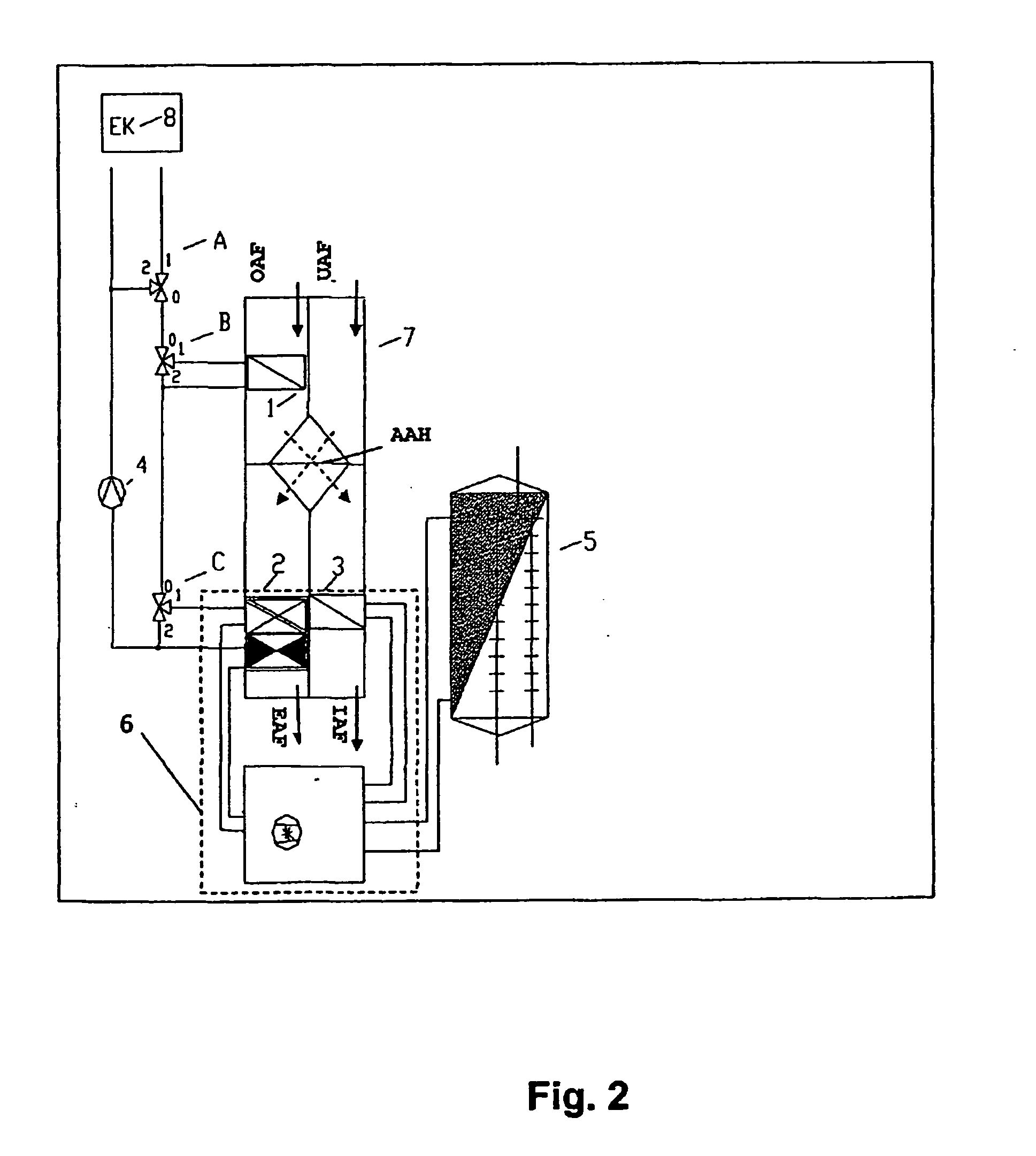

[0008] The present invention is based on the object of specifying an achievement of the object specified above, so that changing over between heating and cooling operation of a heat pump integrated in a building ventilation arrangement is possible using means which are as technically simple as possible to implement. The icing occurring in the known heat pumps is to be largely avoided, and the operational reliability and also the service life of the components participating in the loop of heat pumps are particularly to be improved.

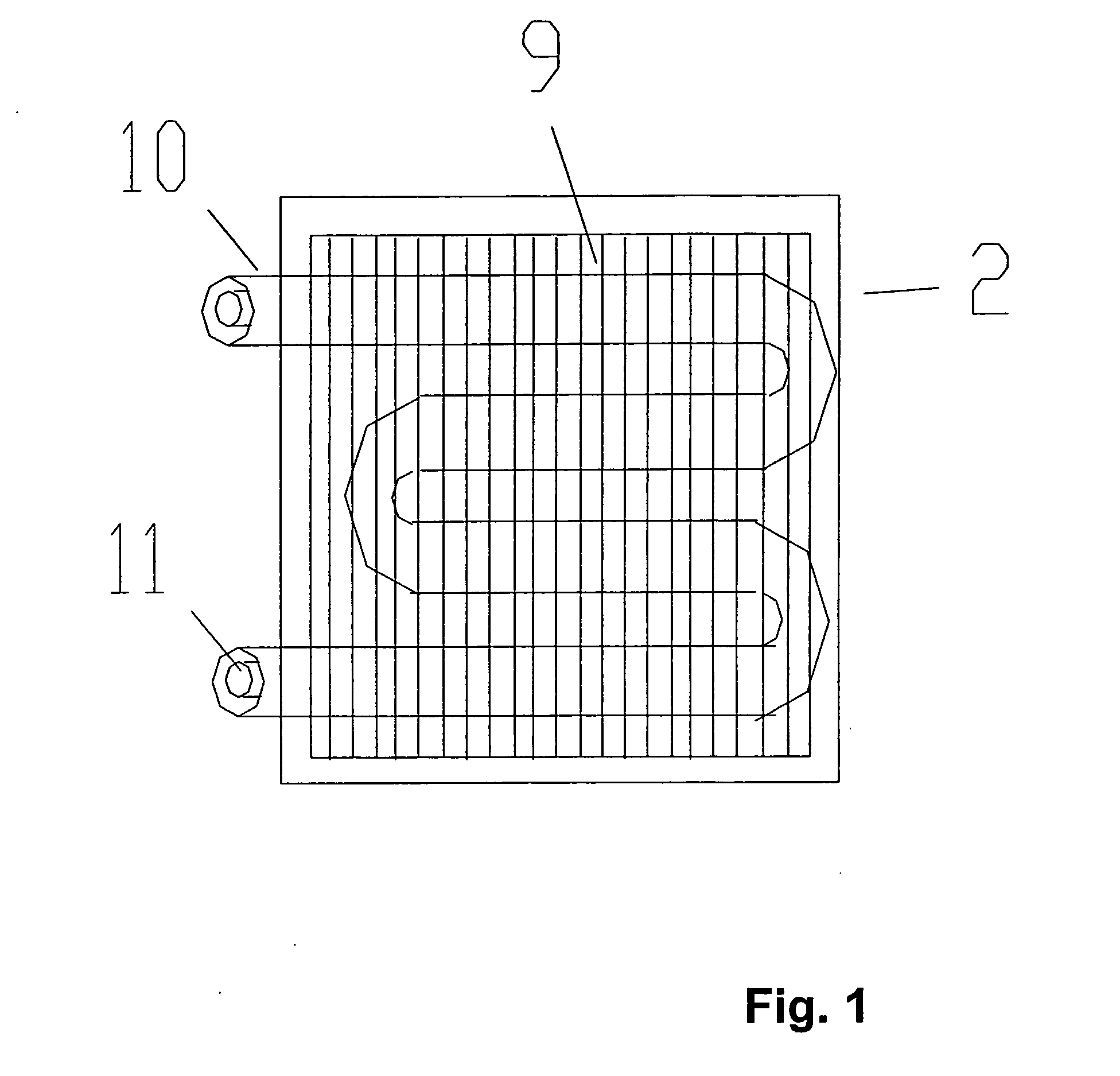

[0009] The achievement of the object on which the present invention is based is specified in Claim 1, which describes a combined fluid-air evaporator, whose use as an evaporator element within a heat pump represents the refinement according to the present invention of a ventilator arrangement for buildings described in Claim 8. Features advantageously refining the idea according to the present invention may be taken from the subclaims and the further descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com