Reinforced heat transfer adsorption regenerator

A technology to strengthen heat transfer and regenerator, applied in boiler absorber, absorbent/adsorbent, heat exchange equipment, etc., can solve the difficulty of sealing and maintenance of processing adsorbent system, large contact thermal resistance between fin and adsorber wall, There are many problems such as solder joints or sealing points, which can improve the practicability and cooling power, facilitate heat transfer, and reduce the amount of metal used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

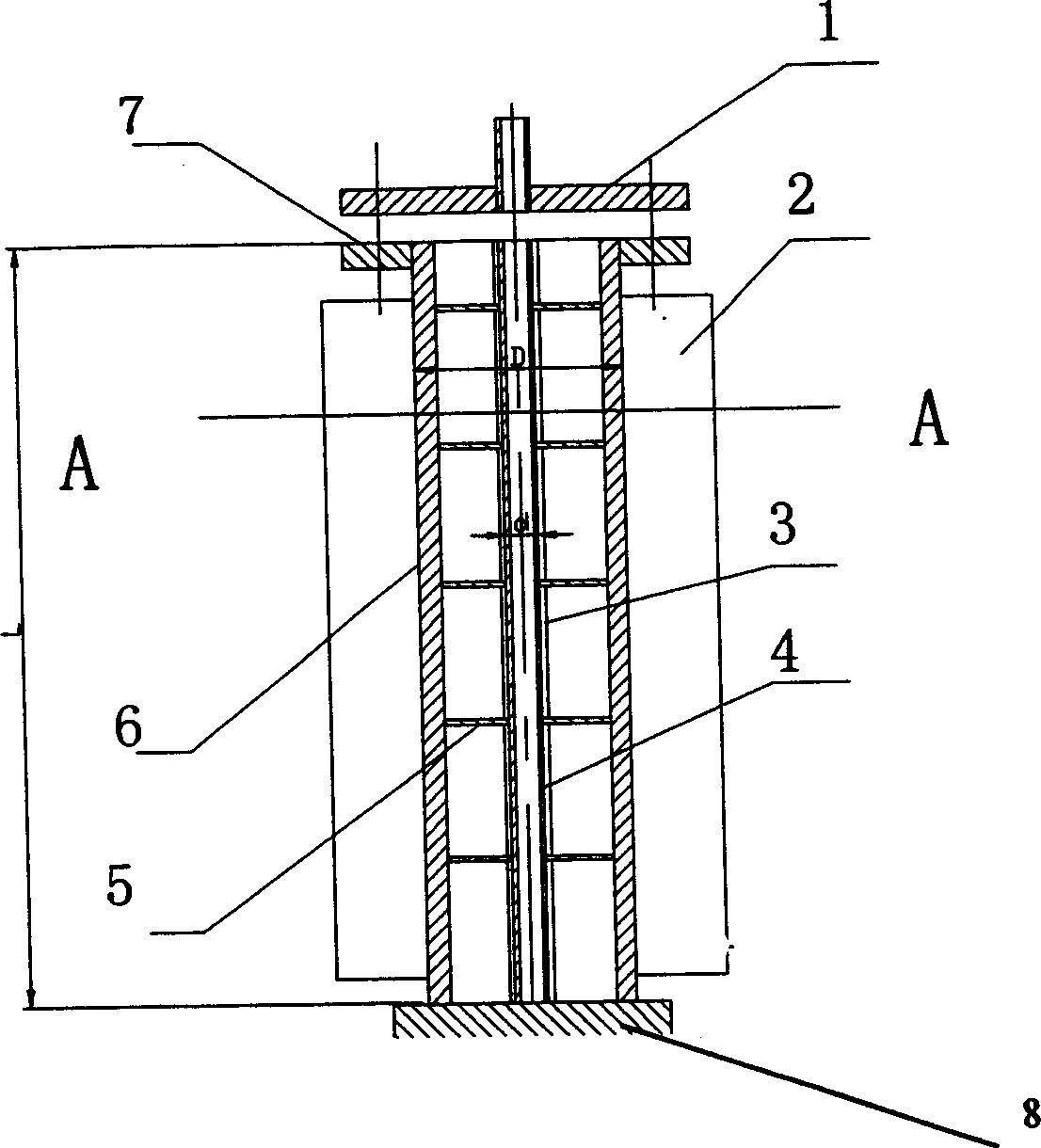

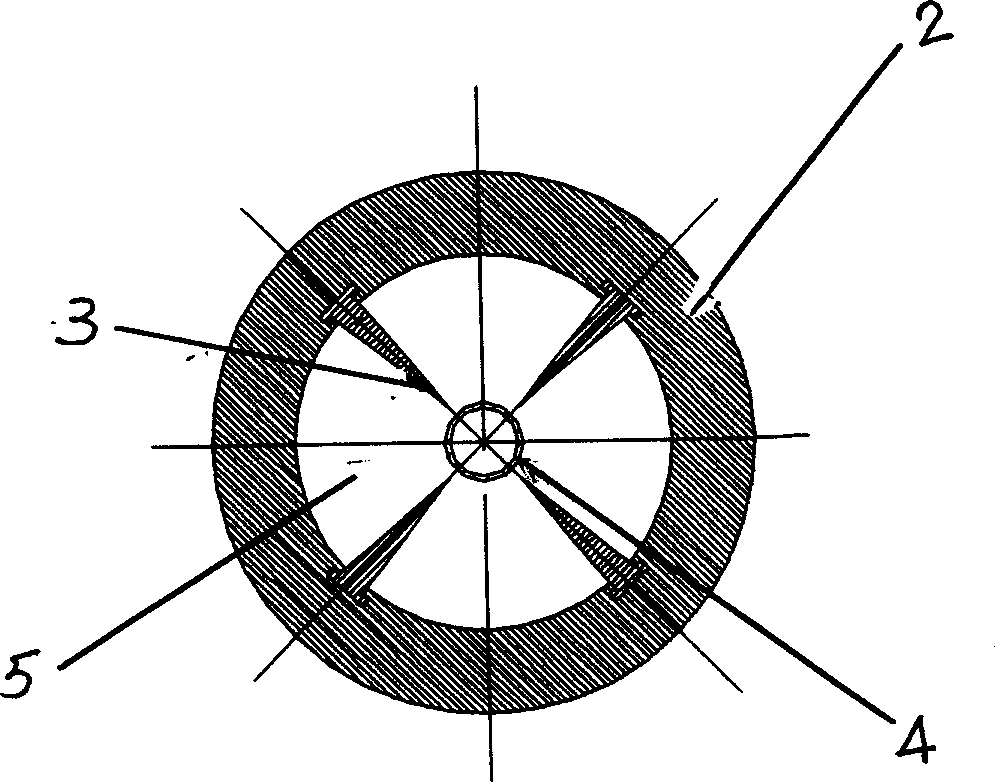

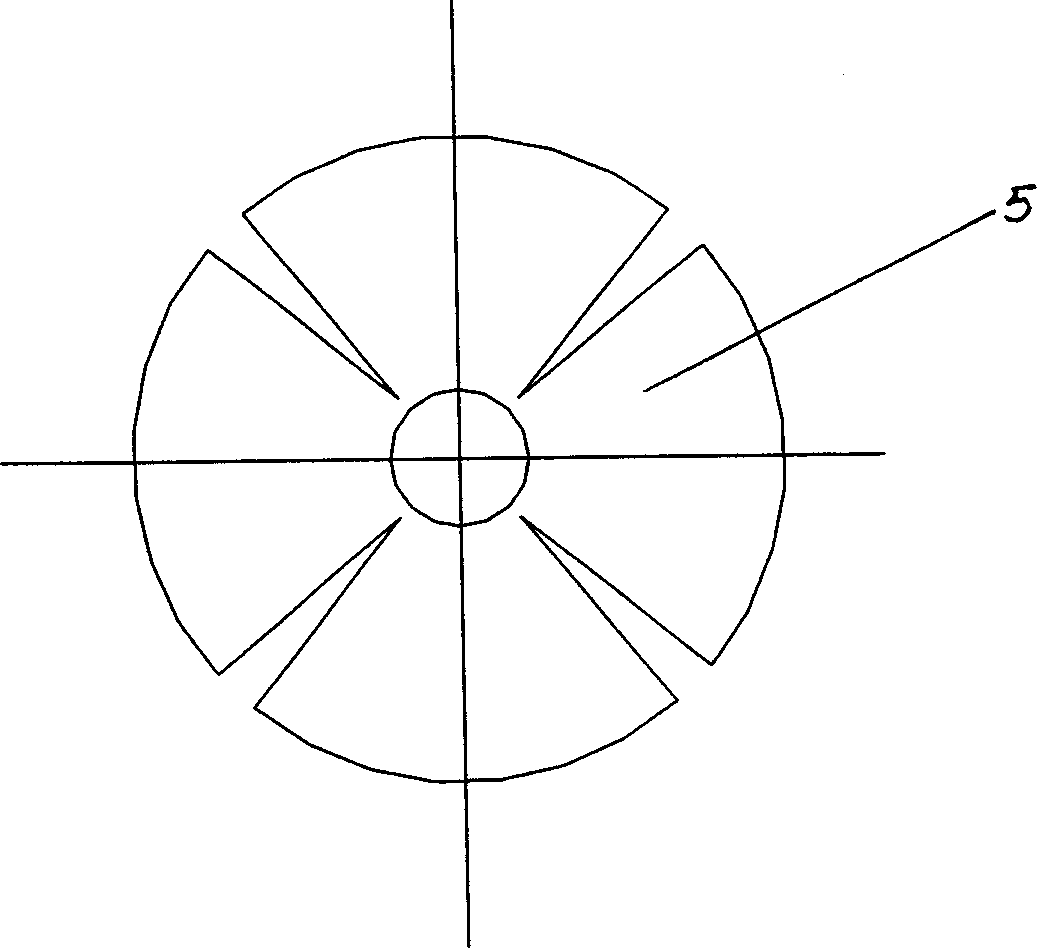

[0019] Such as figure 1 , 2 , 3, and 4, except for the space occupied by the inner radial heat transfer fins 5 and the inner longitudinal heat transfer fins, the blank space between the adsorber main body 6 and the porous tube 4 is the adsorbent installed. pass figure 1 It can be seen from the front view that the high-efficiency adsorber of the present invention utilizes a seamless pipe as the main body 6 of the adsorber, and uses a special processing technology to form grooves of a certain shape inside the seamless pipe as the inner radial fins 5 and inner longitudinal fins. 3 and the embedding groove of the outer fin 2. According to the size of the specific seamless pipe diameter, the inner and outer fins 2, 3, 5, flange 7, and flange cover 1 are processed for future use. Take a small seamless tube and punch small holes on it, the hole diameter is 2-5mm, and the hole spacing is 4-8mm. In order to prevent the adsorbent from entering the porous tube, a layer of 40-80 mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com