Bottom nozzle of nuclear reactor fuel assembly

A fuel assembly and reactor technology, applied in the assembly of fuel elements, reducing greenhouse gases, nuclear power generation, etc., can solve the problems of increased hydraulic resistance coefficient and increased vibration load of fuel elements, and achieve the effect of reducing vibration load and hydraulic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

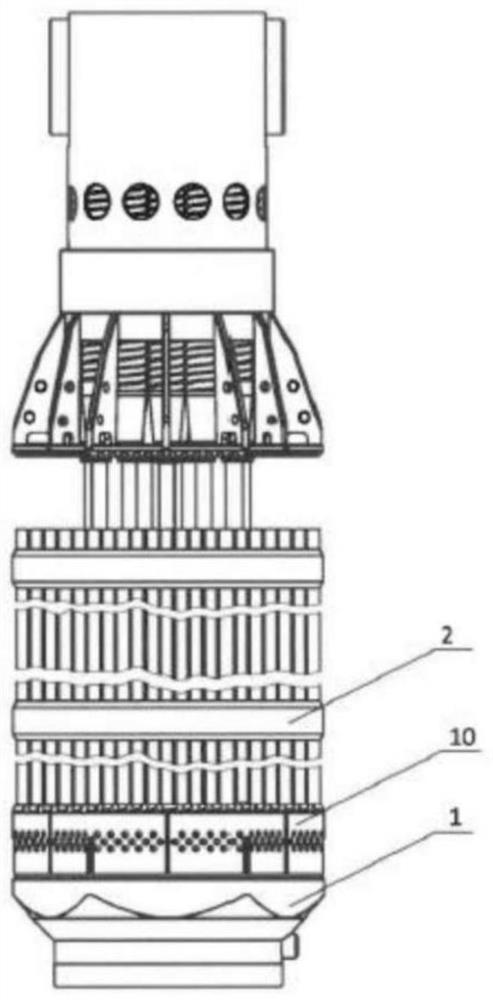

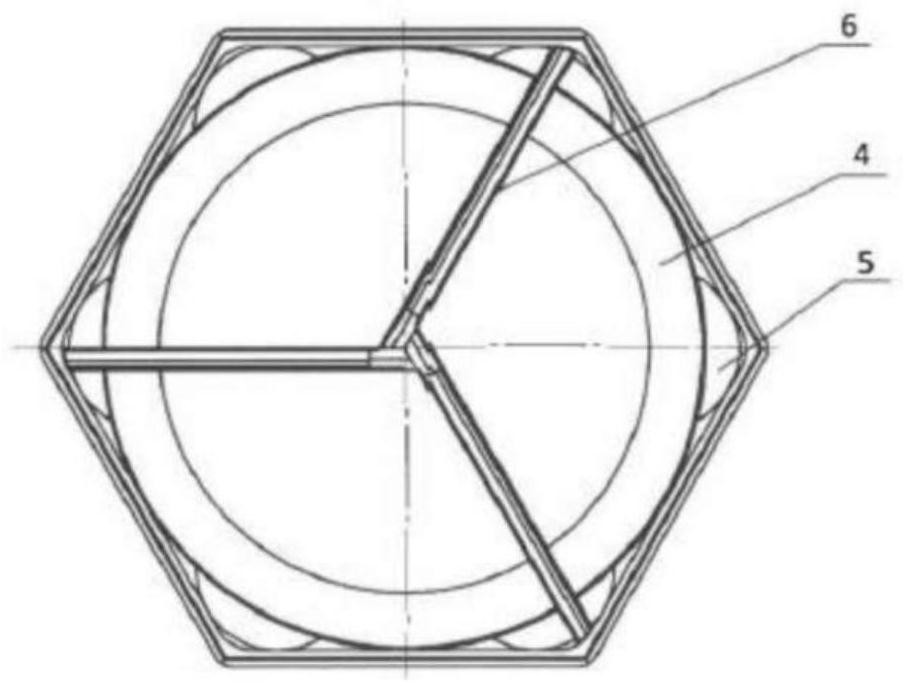

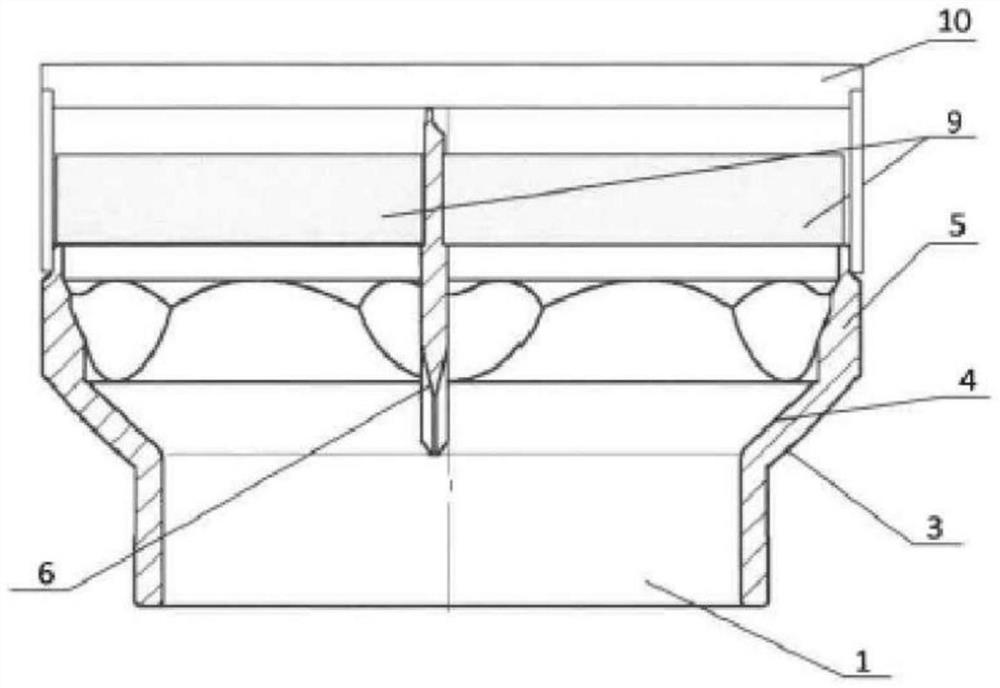

[0025] The tail end 1 of the reactor fuel assembly 2 comprises a coaxial interconnected support element 3 , a diffuser 4 and a hexagonal frame 5 .

[0026] The non-adjacent corners of the hexagonal frame 5 are fixed at offsets from the plane of angular symmetry of the variable height fins 6 .

[0027] There are protrusions 7 and thins 8 on the ribs 6 . The rim of the anti-debris filter is installed in the protrusion 7

[0028] 9. Thin part 8 in contact with the dike between the fuel element bundle support grid 10 pouring holes.

[0029] The top thin part of rib 6 can be made into tooth 11 shape, and the top is flat.

[0030] The tail end works as follows.

[0031] The coolant enters the tail end 1 equipped with an anti-rock debris filter 9, and the outer edge of the filter is installed in the convex part 7 of the rib 6 section, enters the diffuser 4, and freely diffuses radially along the rib 6, And close to the support grid 10 of the fuel element bundle.

[0032] Fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com