A sewage treatment device using continuous biofilm method and its operation process

The technology of a sewage treatment device and operation process, which is applied in the field of sewage biotechnology treatment, can solve the problems of increasing the technological process and difficulty of operation and management of aerated biological filters, unfavorable denitrification by denitrifying bacteria, and increasing carbon dioxide emissions. Small footprint, reduced pipe laying, and the effect of reducing hydraulic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

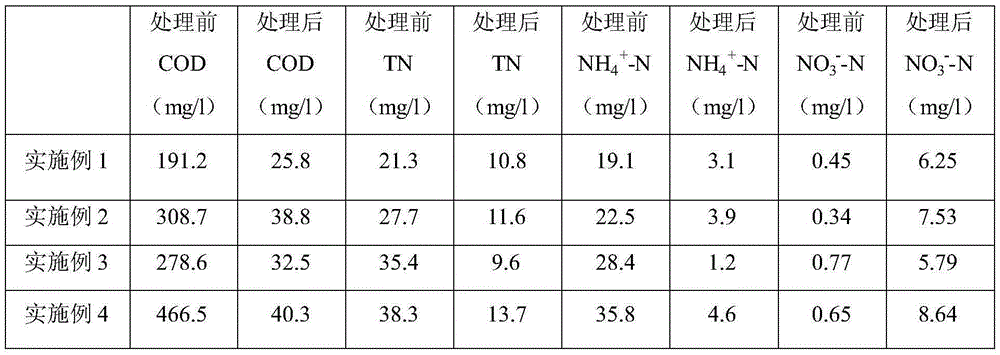

Embodiment 1

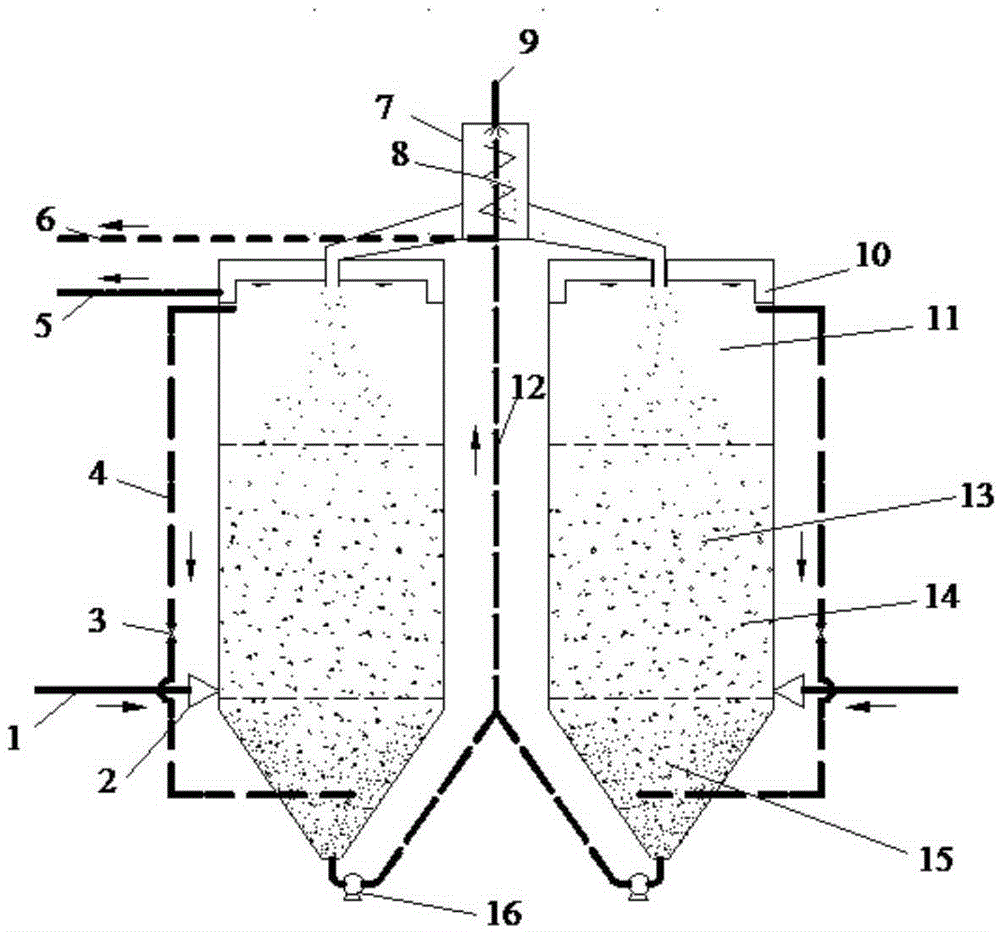

[0022] A sewage treatment device using a continuous biofilm method designed by the present invention includes a water inlet system 1, an aeration system 2, a denitrification system 4, a cleaning system 7 and an integrated biofilm reactor; the integrated biological The membrane reactor is filled with a porous wear-resistant biofiller 14 with a particle size of 4mm; the integrated biofilm reactor is divided into a denitrification zone 15, a nitrification zone 13 and a clean water zone 11 from bottom to top, and the nitrification zone 13 and the denitrification zone The effective volume ratio of 15 is 4:1; the top of the clean water zone 11 is provided with a water outlet tank 10 with a water outlet pipe 5; Its water outlet is set in the denitrification zone 15, and the opening and closing are controlled by the valve 3; the aeration system 2 is connected with the water inlet system 1, and the sewage is pumped into the integrated biofilm reactor through the water inlet system 1 and...

Embodiment 2

[0031] A sewage treatment device using a continuous biofilm method designed by the present invention includes a water inlet system 1, an aeration system 2, a denitrification system 4, a cleaning system 7 and an integrated biofilm reactor; the integrated biological The membrane reactor is filled with a porous wear-resistant biofiller 14 with a particle size of 3mm; the integrated biofilm reactor is divided into a denitrification zone 15, a nitrification zone 13 and a clean water zone 11 from bottom to top, and the nitrification zone 13 and the denitrification zone The effective volume ratio of 15 is 8:1; the upper part of the clean water zone 11 is provided with a water outlet tank 10 with a water outlet pipe 5; Its water outlet is set in the denitrification zone 15, and the opening and closing are controlled by the valve 3; the aeration system 2 is connected with the water inlet system 1, and the sewage is pumped into the integrated biofilm reactor through the water inlet syste...

Embodiment 3

[0040] A sewage treatment device using a continuous biofilm method designed by the present invention includes a water inlet system 1, an aeration system 2, a denitrification system 4, a cleaning system 7 and an integrated biofilm reactor; the integrated biological The membrane reactor is filled with a porous wear-resistant biofiller 14 with a particle size of 5mm; the integrated biofilm reactor is divided into a denitrification zone 15, a nitrification zone 13 and a clean water zone 11 from bottom to top, and the nitrification zone 13 and the denitrification zone The effective volume ratio of 15 is 8:1; the upper part of the clean water zone 11 is provided with a water outlet tank 10 with a water outlet pipe 5; Its water outlet is set in the denitrification zone 15, and the opening and closing are controlled by the valve 3; the aeration system 2 is connected with the water inlet system 1, and the sewage is pumped into the integrated biofilm reactor through the water inlet syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com