Needle brush aerator

An aerator and needle brush technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of low rotor static balance, no breakthrough effect, rotating disk or rotating brush speed Low problems, to achieve the effect of shortening water treatment time, superior flexibility, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

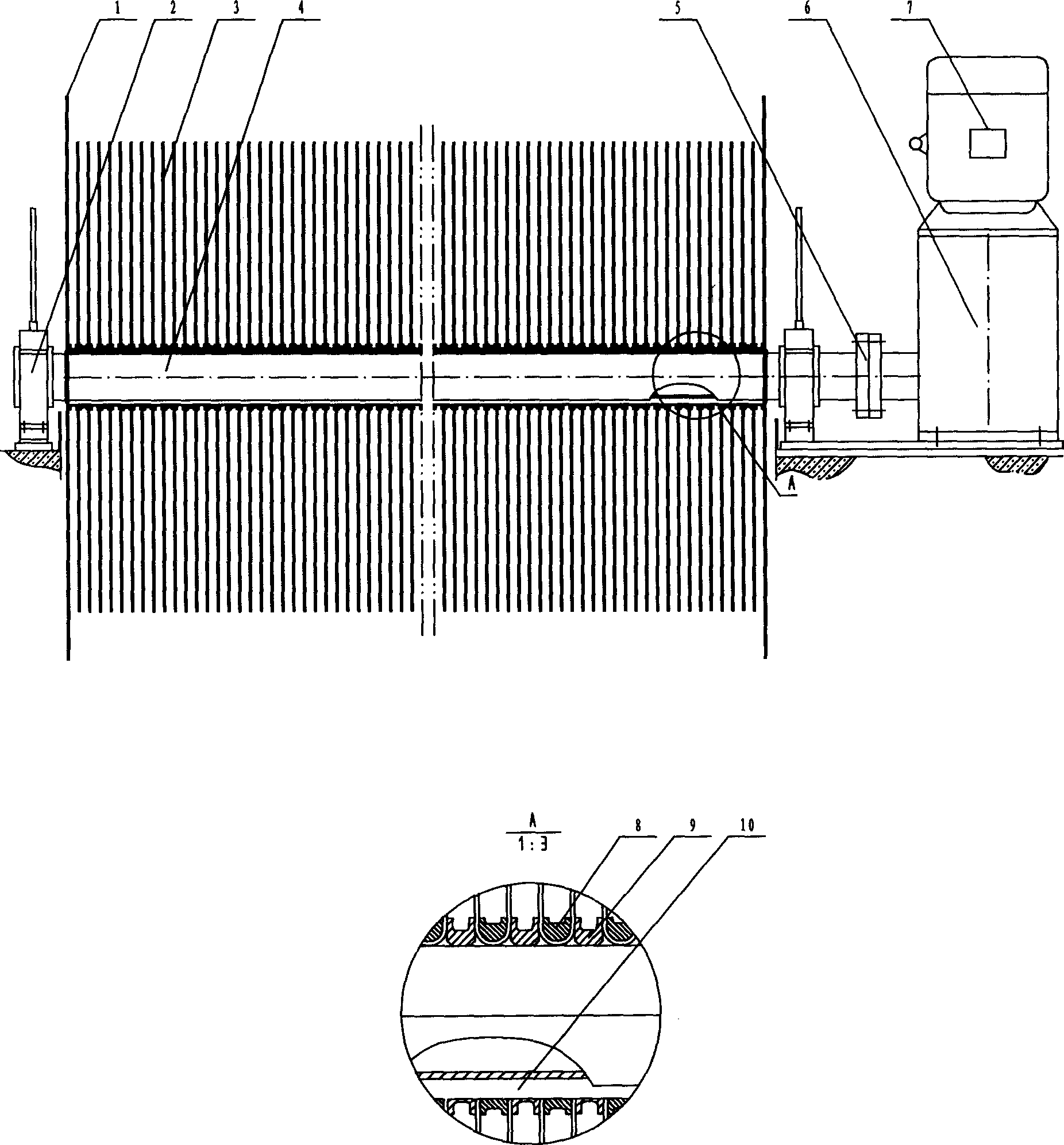

[0018] see figure 1 , this embodiment is a direct series needle brush aerator designed according to the technical solution of the present invention. It includes a needle brush, a horizontal shaft 4, a fog screen 1, a bearing support 2, a shaft coupling 5, a reducer 6 and a motor 7. The single needle seedlings 3 are U-shaped, evenly and densely arranged radially and hung on the positioning ring 8, and the positioning ring 8 on which the needle seedlings 3 are hung is added with the spacer ring 9, which are layered and superimposed on each other. The screen 1 and the elastic retaining ring are combined on the horizontal axis 4.

Embodiment 2

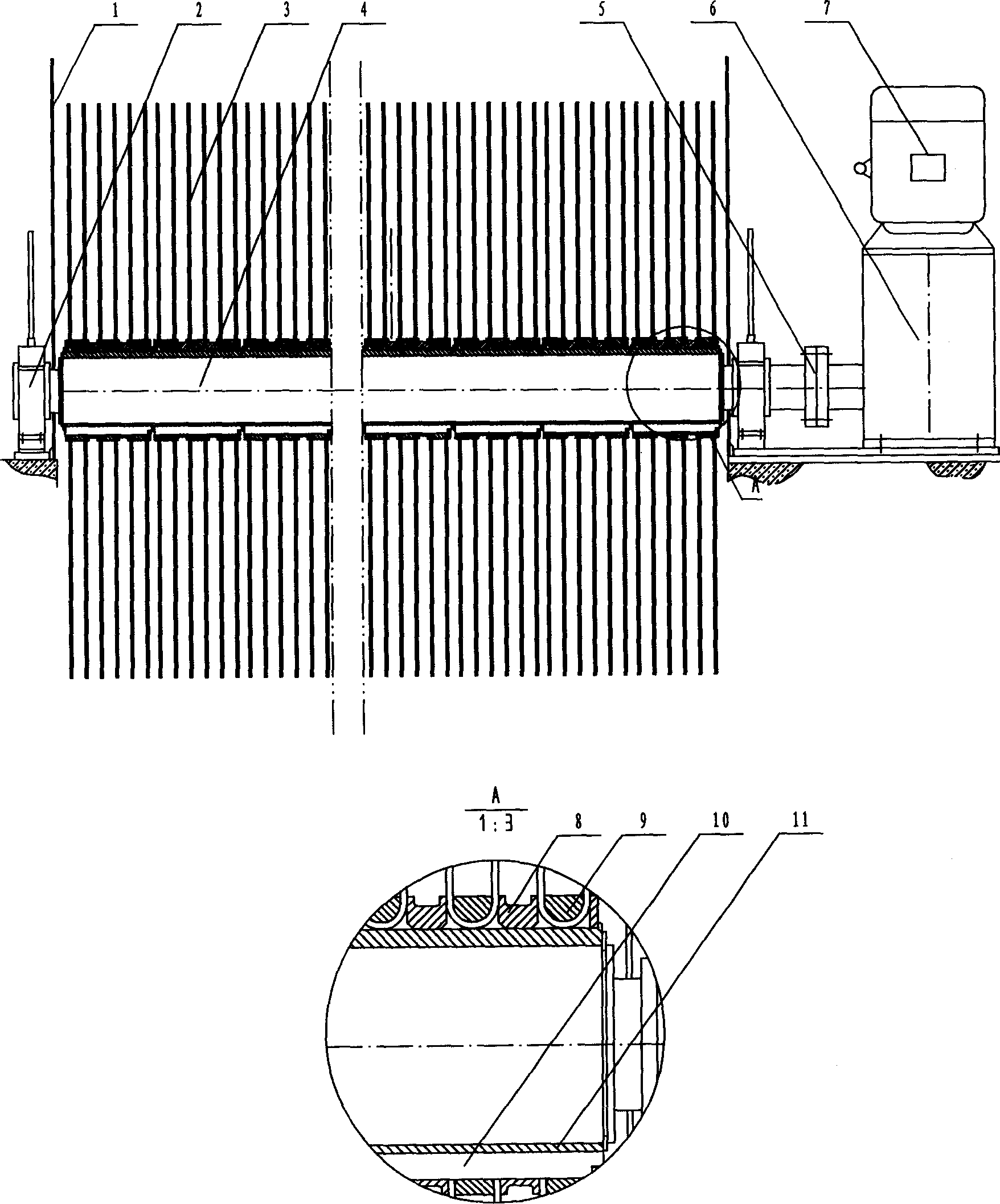

[0020] see figure 1 , the present embodiment is a series-connected needle brush aerator designed according to the technical solution of the present invention. It includes a needle brush, a horizontal shaft 4, a fog screen 1, a bearing support 2, a shaft coupling 5, a reducer 6 and a motor 7. The single needle seedlings 3 are still U-shaped, evenly and intensively arranged radially and hung on the positioning ring 8, and the positioning ring 8 of the needle seedlings 3 plus the spacer ring 9 are stacked in three layers. The pressing plate and the circlip are combined on the wheel hub 11 to form a needle brush unit, and a plurality of needle brush units are connected in series on the horizontal shaft 4, and the units are connected with the horizontal shaft 4 with a key, and the circlip is limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com