A process method for anti-corrosion and anti-cavitation of impeller of water ring vacuum pump

A process method and vacuum pump technology, applied in anti-corrosion coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc. Reasonable design of impeller coating, improved gas impact resistance, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

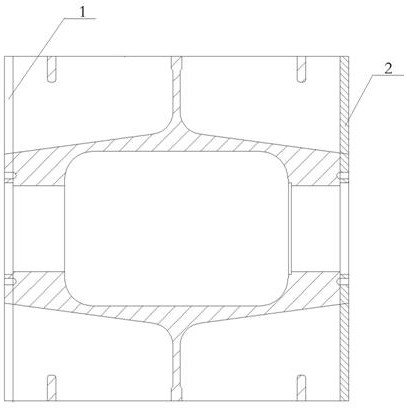

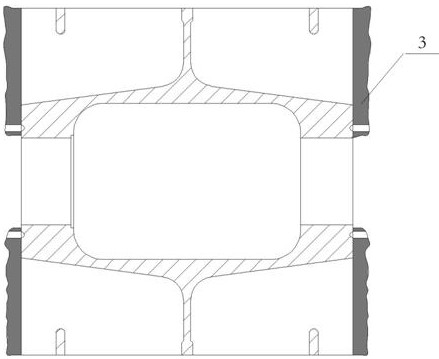

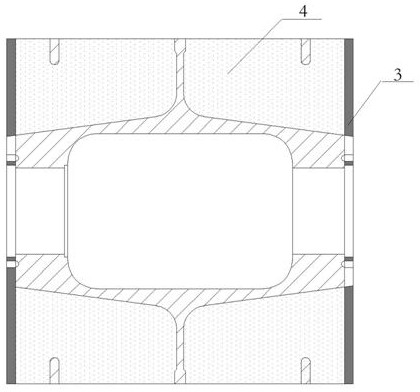

Image

Examples

Embodiment 1

[0034] A process method for anti-corrosion and anti-cavitation of a vacuum pump impeller, comprising the following steps:

[0035] Weigh 100g of bisphenol A epoxy resin (epoxy equivalent of 180), 30g of alumina powder (average particle size of 0.03mm), 2g of silane coupling agent, 7g of polyamine curing agent (triethylenetetramine g), Curing accelerator (2,4,5-tris(dimethylaminomethyl)phenol) 2g, mixed evenly to obtain primer A; (2) Weigh 80g of bisphenol A epoxy resin (epoxy equivalent 180) , Alumina powder (average particle size 0.03mm) 30g, silicon carbide powder (average particle size 0.03mm) 150g, toughening agent (liquid hydroxynitrile rubber) 5g, thickening thixotropic agent (fumed silica) 2g, polyamine curing agent (N-aminoethylpiperazine) 8g, mixed evenly to obtain paste material B; (3) Weigh 50g of bisphenol A epoxy resin (epoxy equivalent of 180), silicon carbide powder (average particle size 0.03mm) 100g, leveling agent (polydimethylsiloxane) 2g, polyamine curing ...

Embodiment 2

[0037] A process method for anti-corrosion and anti-cavitation of a vacuum pump impeller, comprising the following steps:

[0038](1) Weigh 80g of bisphenol A epoxy resin (epoxy equivalent of 180), 20g of alumina powder (average particle size of 0.03mm), 2g of silane coupling agent, polyamine curing agent (triethylenetetramine) 5g, 2g of curing accelerator (2,4,5-tris(dimethylaminomethyl)phenol), mixed evenly to obtain primer A; (2) Weigh bisphenol A epoxy resin (epoxy equivalent of 180 ) 100g, alumina powder (average particle size 0.03mm) 20g, silicon carbide powder (average particle size 0.03mm) 200g, toughening agent (liquid hydroxynitrile rubber) 5g, thickening thixotropic agent (gas phase dioxide Silicon) 2g, polyamine curing agent (N-aminoethylpiperazine) 10g, mix evenly to obtain paste material B; (3) Weigh 80g of bisphenol A epoxy resin (epoxy equivalent is 180), carbonize Silicon powder (average particle size: 0.03mm) 100g, leveling agent (polydimethylsiloxane) 2g, p...

Embodiment 3

[0040] A process method for an anti-corrosion and cavitation-resistant coating for a vacuum pump impeller, comprising the following steps:

[0041] Weigh 50g of bisphenol A epoxy resin (epoxy equivalent of 180), 40g of alumina powder (average particle size of 0.03mm), 1g of silane coupling agent, 10g of polyamine curing agent (triethylenetetramine), and cure Accelerator (2,4,5-tris(dimethylaminomethyl)phenol) 1g, mixed evenly to obtain primer A; (2) Weigh 50g of bisphenol A epoxy resin (epoxy equivalent 180), Alumina powder (average particle size 0.03mm) 40g, silicon carbide powder (average particle size 0.03mm) 100g, toughening agent (liquid hydroxynitrile rubber) 5g, thickening thixotropic agent (fumed silica) 2g , polyamine curing agent (N-aminoethylpiperazine) 5g, mixed evenly to obtain paste material B; (3) Weigh 100g of bisphenol A epoxy resin (epoxy equivalent of 180), silicon carbide powder ( Average particle size is 0.03mm) 50g, leveling agent (polydimethylsiloxane) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com