Double-runner cone valve

A technology of cone valve and double flow channel, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems affecting the volume coefficient of the pump (volume efficiency, increase the manufacturing cost, large vibration and noise, etc., and achieve the improvement of volume coefficient, Strong flow capacity, low vibration and noise of the pump valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

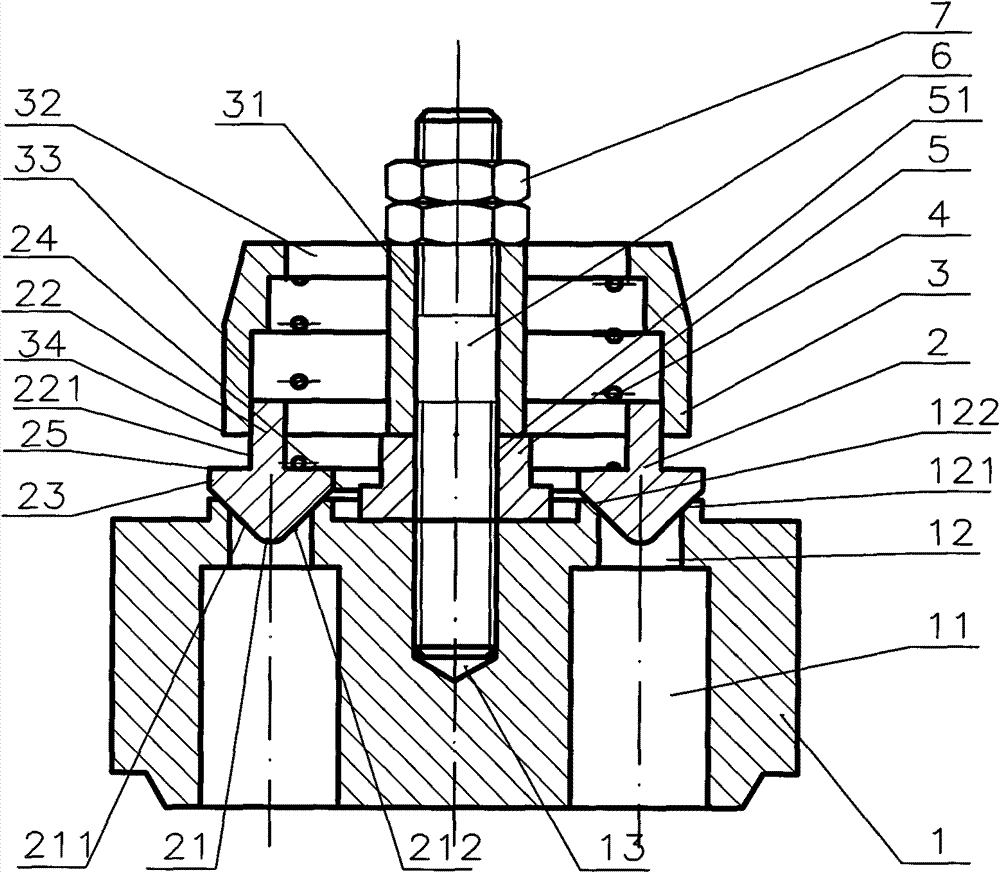

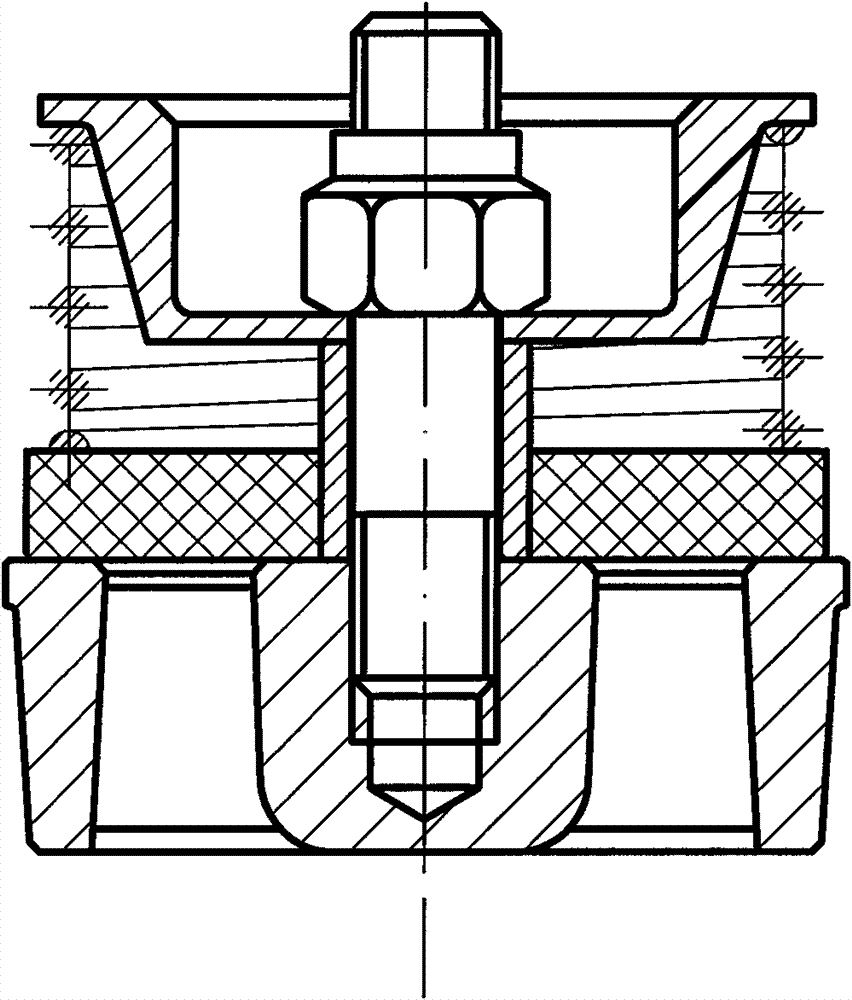

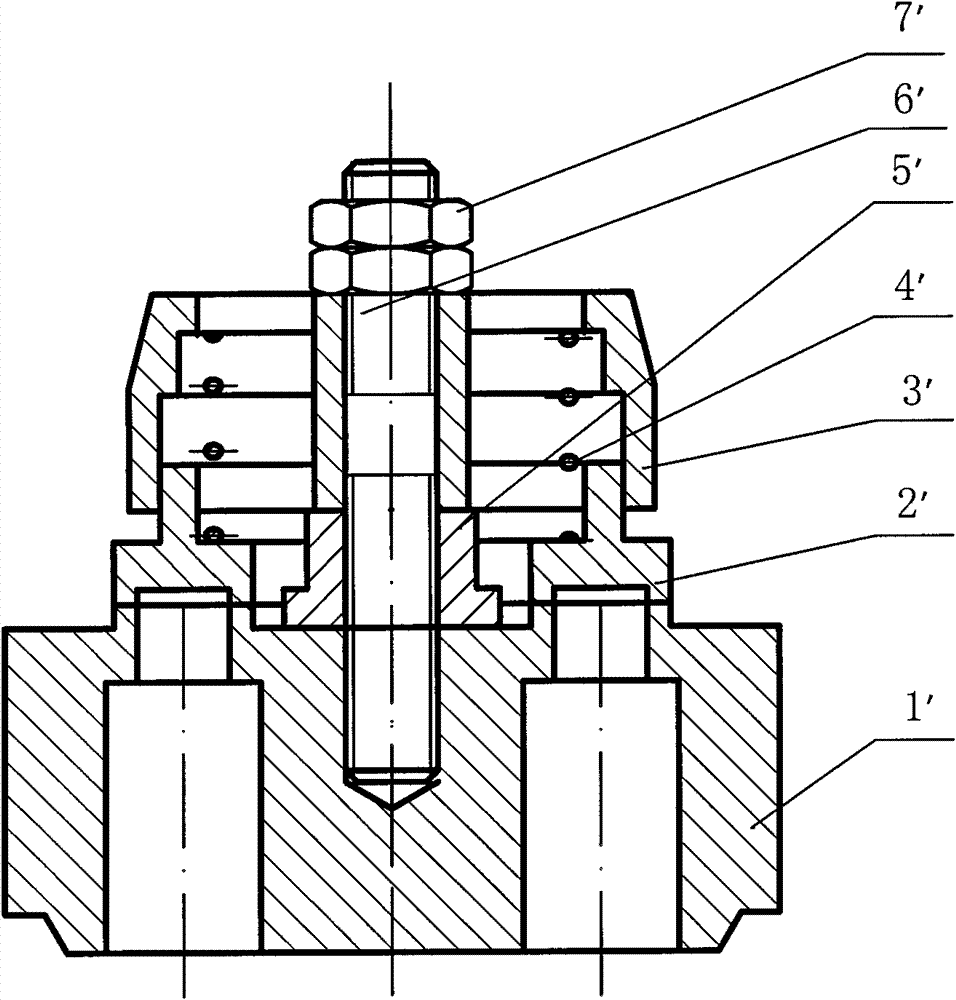

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] See figure 1 As shown, the lower part of the valve seat 1 of the double-channel conical valve of the present invention has a plurality of non-penetrating holes 11 evenly distributed in the circumferential direction, and an annular groove 12 is formed on the upper part, and the annular groove 12 communicates with the lower hole 11 of the valve seat, and The central circumference lines of the two coincide. The mouth of the annular groove 12 is designed as a tapered mouth narrowed at the bottom, and its two annular surfaces 121, 122 form an included angle of 45° with the upper plane of the valve seat, so that the two planes at the upper end of the annular flow channel of the valve seat 1 form a 90° included angle. There is a threaded hole 13 in the center of the valve seat 1, which can be used for screw connection.

[0030] The valve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com