Preparation method of foldable thermochromic device based on nanowire film

A thermochromic and nanowire technology, applied in replication/marking methods, instruments, nonlinear optics, etc., can solve problems such as inability to meet foldable thermochromic devices, affecting thermochromic speed, and poor particle structure flexibility. To achieve the effect of convenient low-cost large-scale promotion, rapid discoloration, and little impact of environmental fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a foldable thermochromic device based on a nanowire film, comprising the following steps:

[0022] Step 1: Automatically scrape and coat the metal nanowire conductive ink on the flexible transparent substrate by an automatic scraper coating device, and then obtain a flexible metal nanowire film after drying. The specific process is as follows:

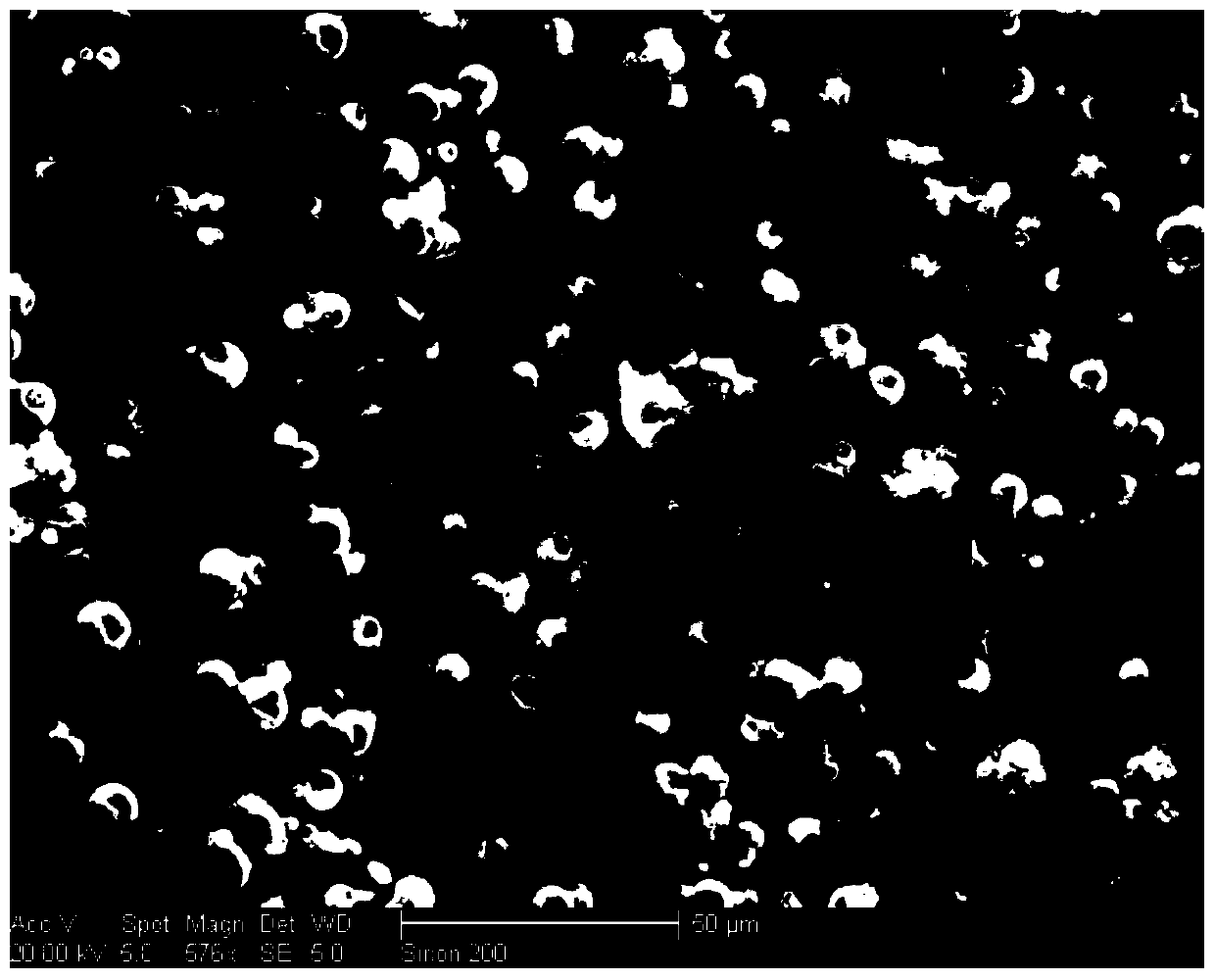

[0023] Spread the flexible substrate on the panel of the automatic scraper coater, open the panel for negative pressure adsorption, so that the substrate is firmly flattened on the panel; choose different types of Meyer rods to prepare metal nanowire films with different surface resistances, and place the Meyer rods Place it on the poles on both sides of the automatic scraper, spread the conductive ink of metal nanowires in a straight line along the inner side of the Mayer rod on the flexible substrate in front of the Meyer rod, set the running speed, and start the automatic scraper. Make the Meyer rod mo...

Embodiment 2

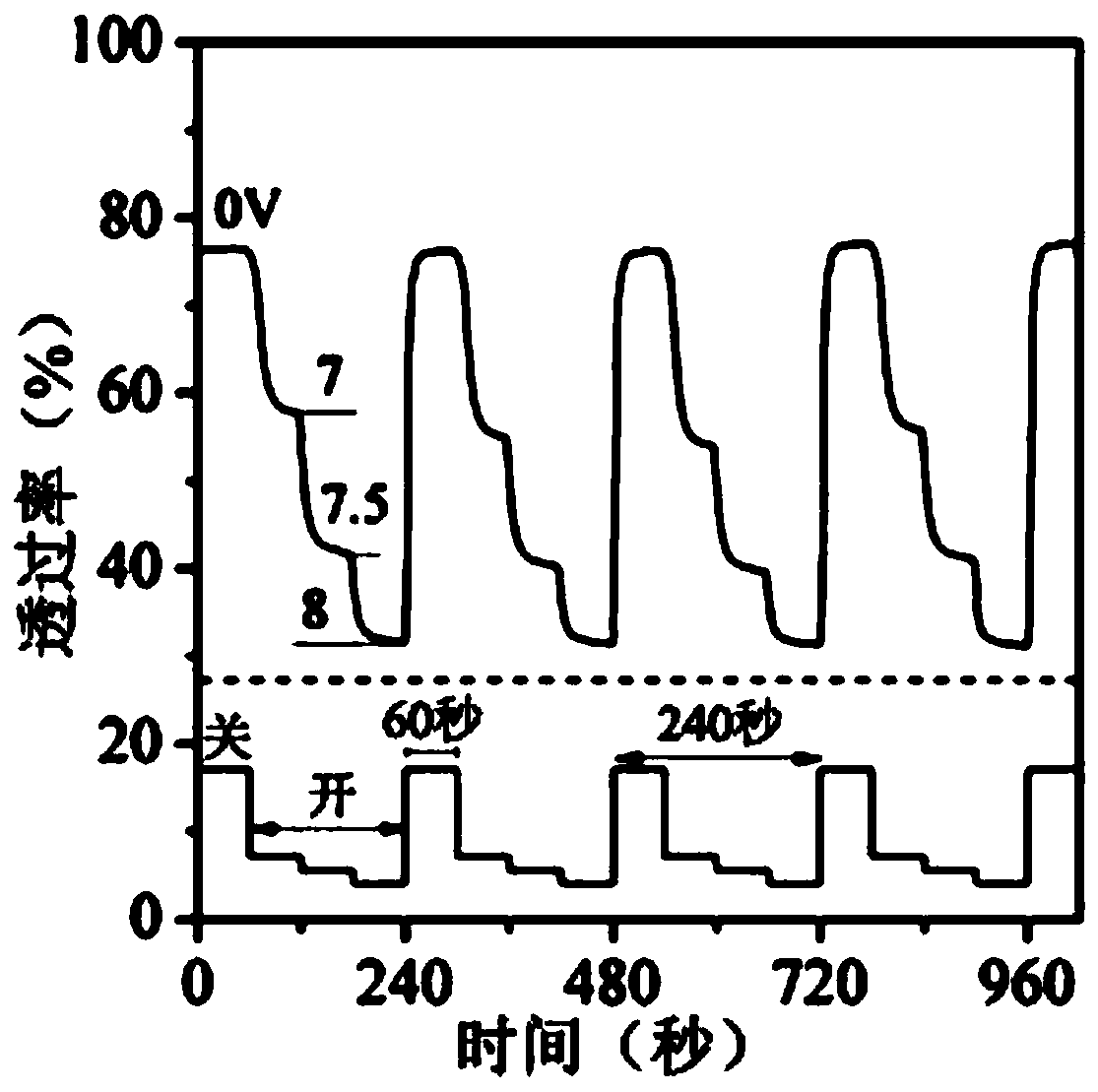

[0032] A method for preparing a foldable thermochromic device based on a nanowire film, comprising the following steps:

[0033] Step 1: Printing thermochromic display objects on a flexible substrate with an inkjet printer; where thermochromic inks with different changing temperatures are used to sequentially print thermochromic display objects with different changing temperatures. The specific process is as follows:

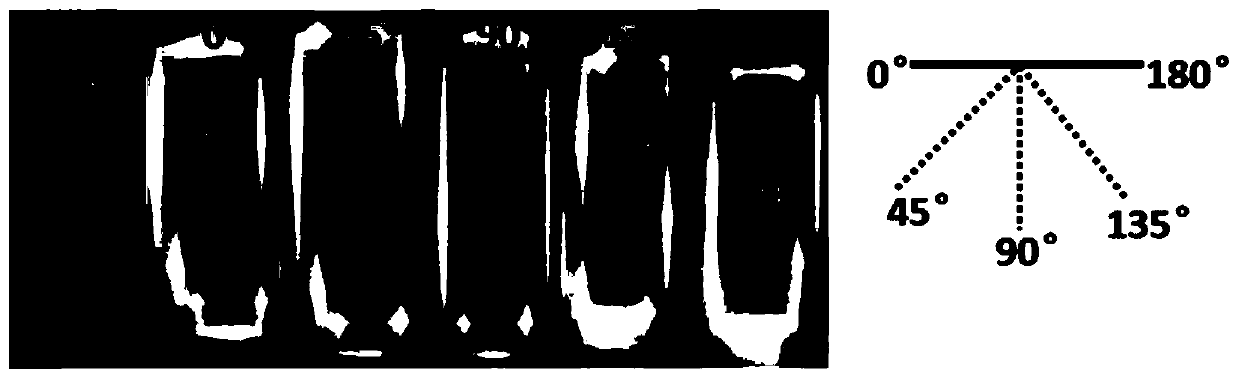

[0034] Lay the flexible substrate on the working plate of the inkjet printer, and position the substrate in place in two dimensions and in one dimension; inject a thermochromic ink into the ink cartridge through the filter, and connect the ink cartridge to the nozzle of the inkjet printer Assembled and connected, put it into the inkjet printer; use the inkjet printer's own software to design the target thermochromic display object graphics, control the work of the inkjet printer according to the designed display object graphics, and control the display through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com