Heat exchanger

A heat exchanger and fin technology, applied in the field of heat exchangers, can solve the problems of increasing the defrosting time of the heat exchanger, narrowing the space of tubes and fins, reducing heat exchange efficiency, etc. The effect of air volume and long flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. However, the idea of the present invention is not limited to the suggested embodiments, and those skilled in the art who understand the idea of the present invention can easily propose other embodiments within the scope of the same idea.

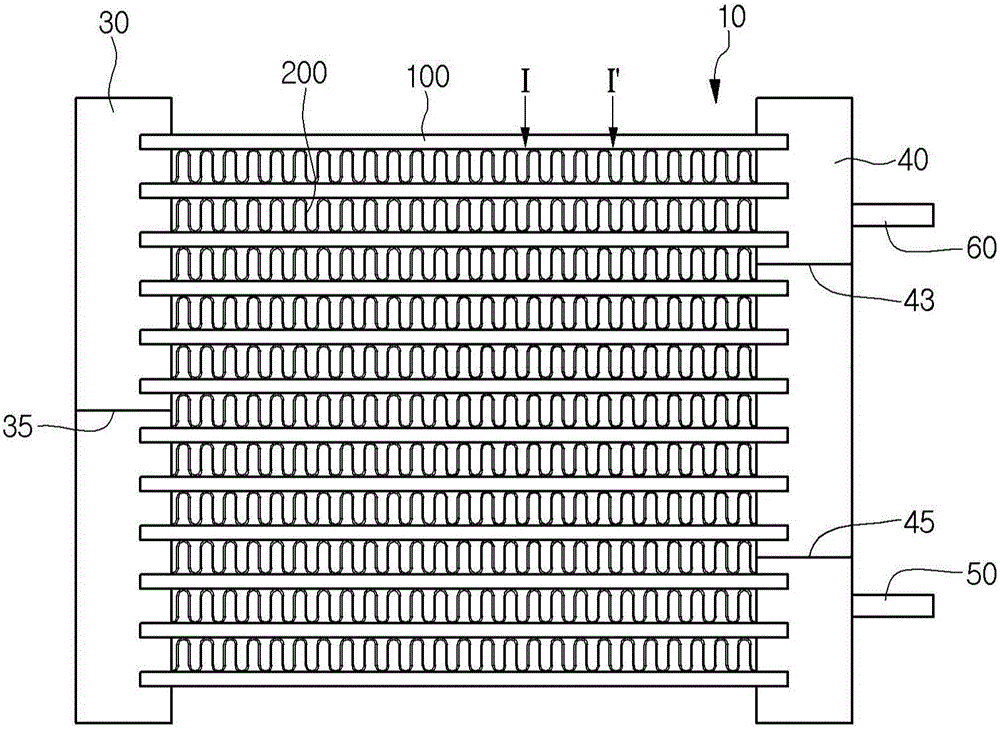

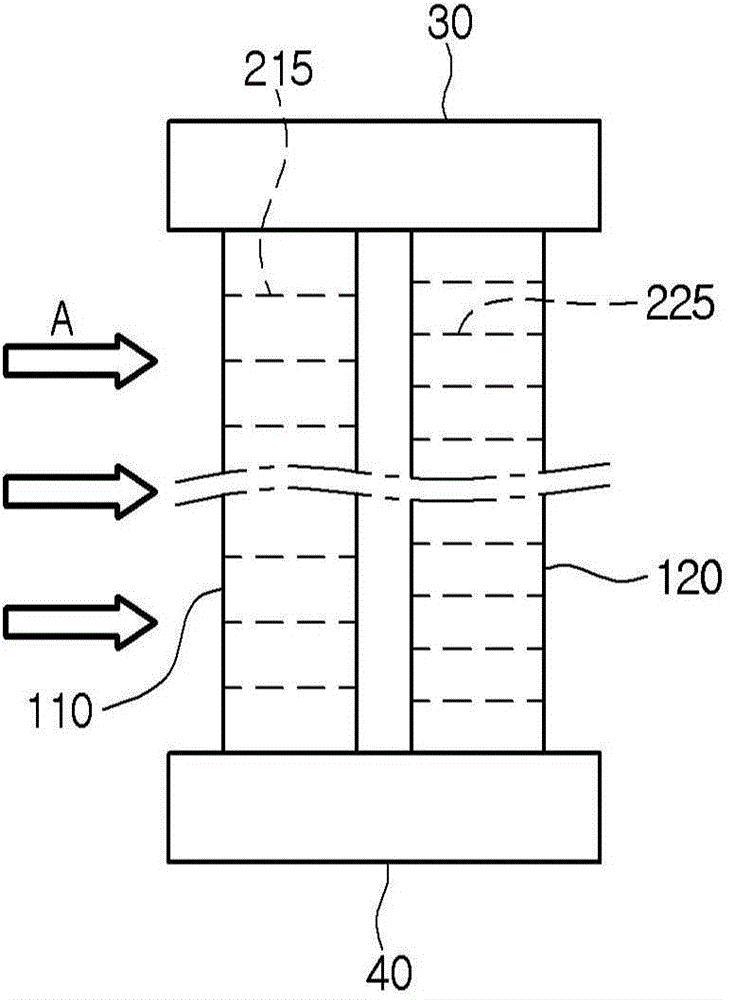

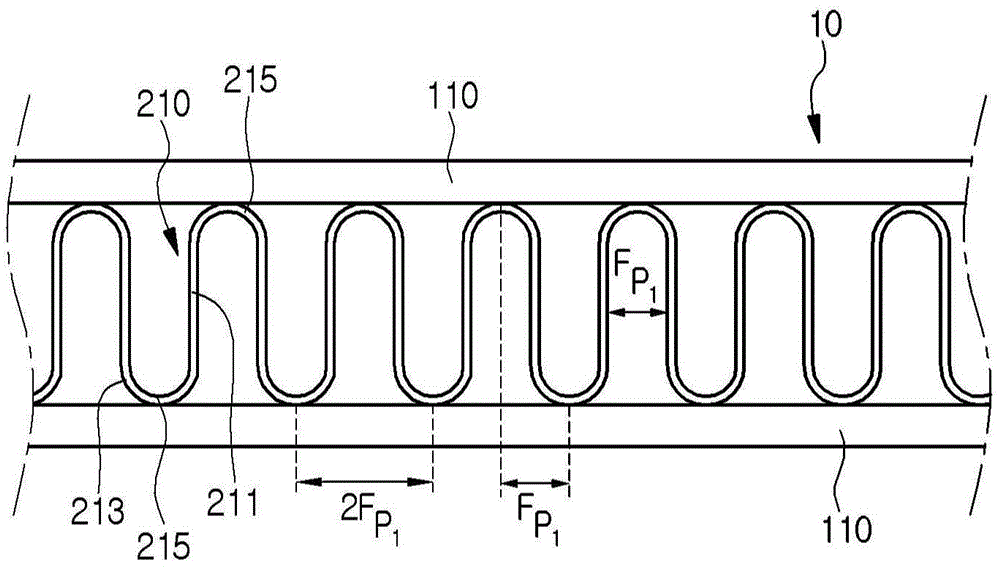

[0044] figure 1 It is a front view showing the structure of the heat exchanger of the first embodiment of the present invention.

[0045] refer to figure 1 , The heat exchanger 10 of the first embodiment of the present invention includes: a plurality of refrigerant tubes (hereinafter, "tubes") 100 capable of causing refrigerant to flow; a plurality of fins 200 stacked on the above-mentioned refrigerant tubes 100; and two Two heads 30, 40 are connected to the two ends of the above-mentioned refrigerant pipe 100.

[0046] The plurality of refrigerant tubes 100 have a predetermined length, are arranged long in parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com