Rotary heating and temperature control device in combined spinning process of dissimilar metal

A composite spinning and rotating heating technology, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., to achieve the effects of stable and reliable circuit connection, convenient control, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

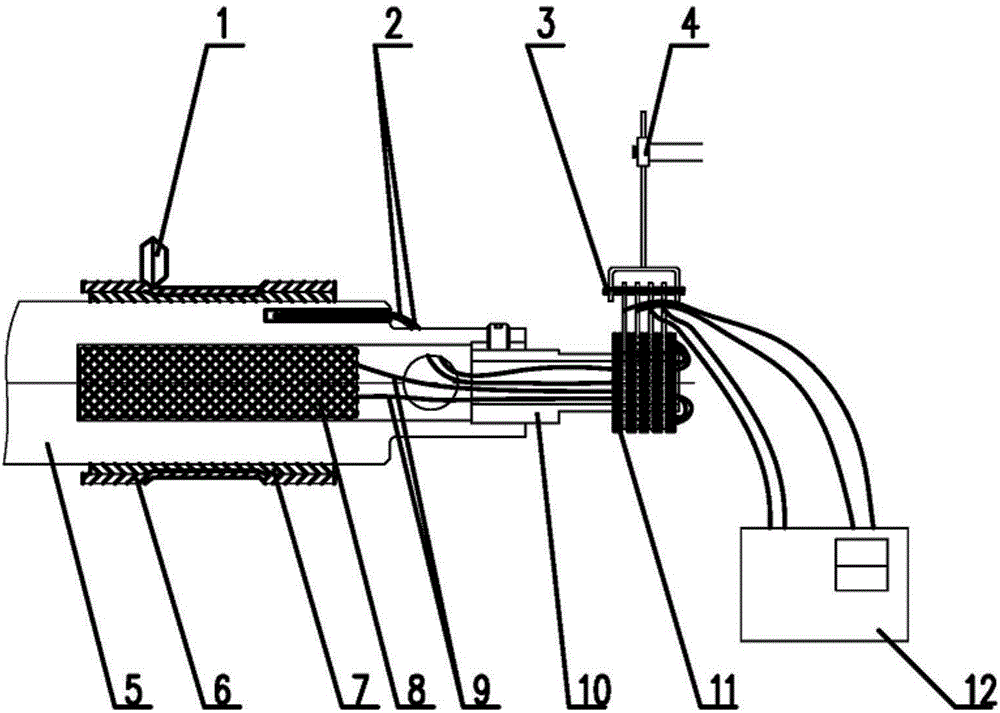

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, the device described in this embodiment includes a thermocouple wire 2, a carbon brush holder 3, a lifting controller 4, a mandrel 5, an outer tube 6, an inner tube 7, a heating rod 8, a heating rod power cord 9, a core Shaft collector ring connector 10, four-way collector ring 11 and intelligent temperature controller 12, the mandrel 5 is installed in the inner tube 7, the inner tube 7 is installed in the outer tube 6, the built-in heating rod 8 of the mandrel 5, the core The end of the shaft 5 is connected to the mandrel slip ring connector 10 through a connection joint, and the inside of the mandrel slip ring connector 10 has a through hole for inserting the thermocouple wire 2 and the heating rod power line 9, and the mandrel The other end of the slip ring connector 10 is fixed with four slip rings 11, two of the four slip rings 11 are connected to the heating rod power line 9, and the rema...

specific Embodiment approach 2

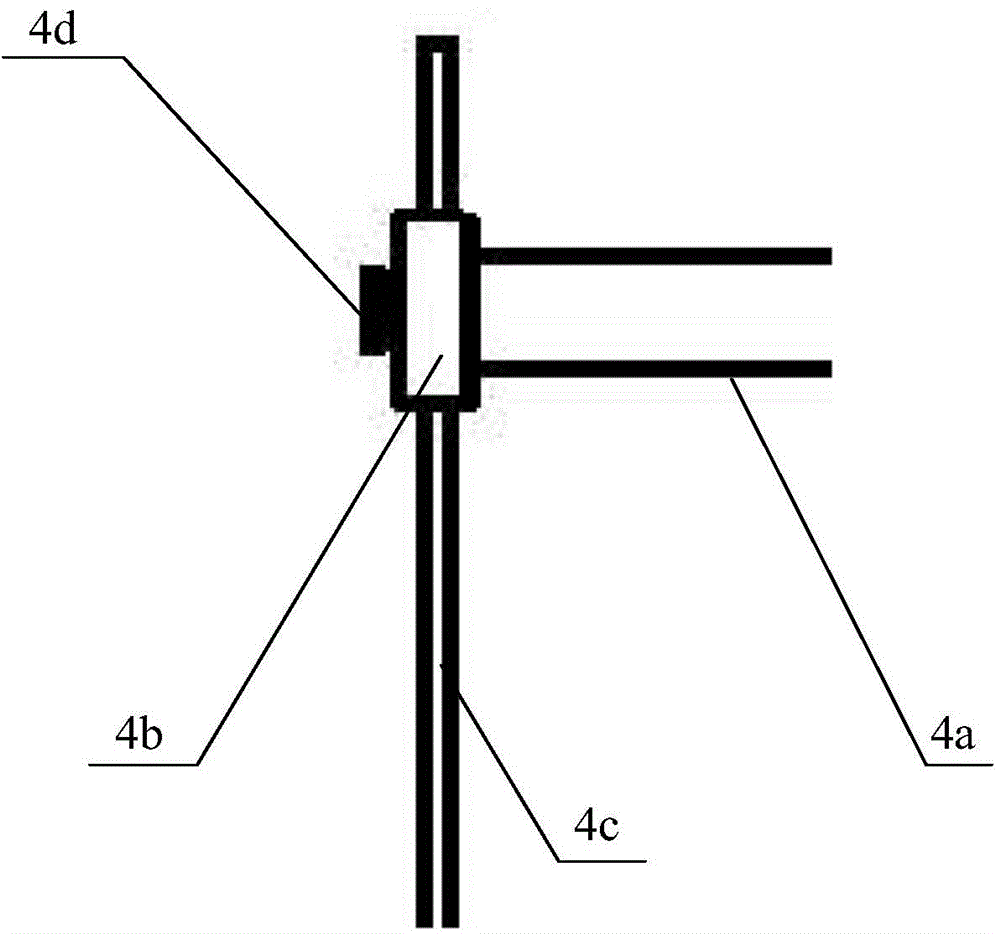

[0011] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment is that the lifting controller includes a bracket 4a, a sleeve 4b, a lifting rod 4c and a jacking wire 4d, the end of the bracket has a sleeve 4b, and the lifting rod 4c can slide up and down in the sleeve 4b, through Tightening the top wire 4d on the side of the sleeve 4b can fix the lifting rod 4c at a certain position, so as to easily realize the combination and separation of the collector ring and the carbon brush, and facilitate the loading and unloading of the tube blank. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 This embodiment is described. The connecting joint of this embodiment is provided with a threaded hole, and the threaded hole is used for screwing in a top screw to fasten the connection of the mandrel. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com