High-temperature Hopkinson pressure bar experimental system with atmosphere protection device

A technology of Hopkinson pressure rods and protective devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of releasing toxic gases, not being able to provide an experimental environment that meets specific requirements, and high-temperature oxidation, so as to reduce damage and reduce and avoid oxidation and the effect of releasing toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The experimental method of this embodiment adopts the method of keeping the waveguide rod separated from the test piece during heating, heating only on the test piece, and completing the assembly of the test piece and waveguide rod before the impact, and equipped with a two-way double-air path automatic assembly device.

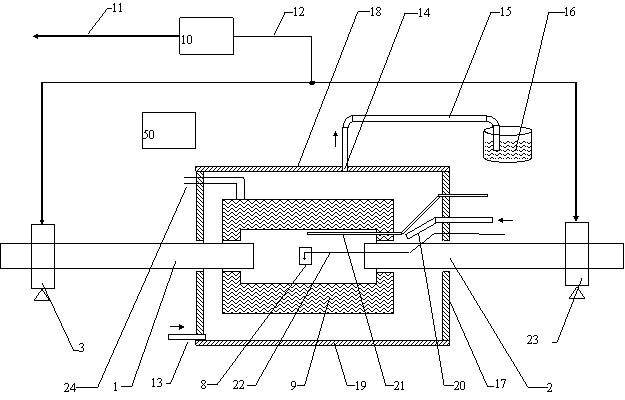

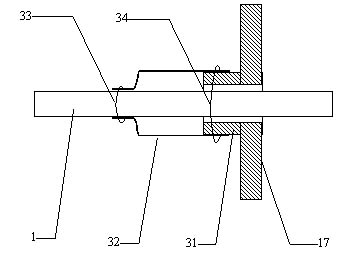

[0025] figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of the high-temperature Hopkinson pressure bar experimental system with an atmosphere protection device of the present invention, image 3 It is a schematic diagram of the connection structure between the waveguide rod and the protective box in Embodiment 1 of the high-temperature Hopkinson pressure rod experimental system with an atmosphere protection device. from figure 1 , image 3 It can be seen from the figure that the overall structure of the high-temperature Hopkinson pressure bar experimental system with an atmosphere protection device of the present invention ...

Embodiment 2

[0033] The experimental method of this embodiment adopts the experimental method of heating the test piece and the waveguide rod at the same time, and the waveguide rod does not need to be moved.

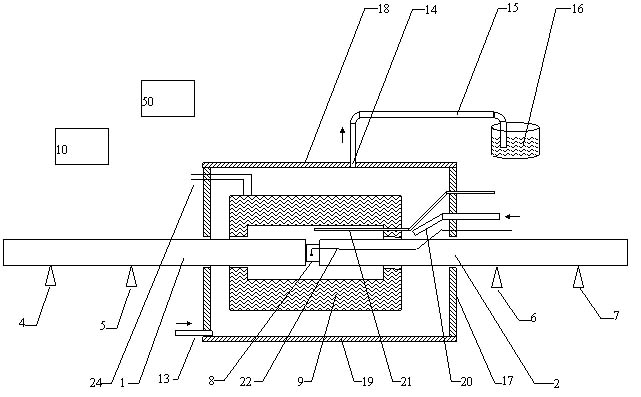

[0034] figure 2 It is a schematic diagram of the overall structure in Embodiment 2 of the high-temperature Hopkinson pressure bar experimental system with an atmosphere protection device of the present invention, Figure 4 It is a schematic diagram of the connection structure between the waveguide rod and the protective box in Example 2 of the high-temperature Hopkinson pressure rod experimental system with an atmosphere protection device. from figure 2 , Figure 4 It can be seen from the figure that the overall structure of the high-temperature Hopkinson pressure bar experimental system with an atmosphere protection device of the present invention includes an atmosphere protection device, a heating system and a loading system. The atmosphere protection device includes a protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com