Composite nanofiltration membrane and preparation method thereof

A technology of composite nanofiltration membrane and ultrafiltration membrane, which is applied in the field of preparation of nanofiltration membrane and nanofiltration membrane, can solve the problems of inability to realize water softening ability, uncontrollable separation layer thickness, large fluctuation of nanofiltration membrane performance, etc. Achieve the effect of low working pressure, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of heavy metal adsorption support layer

[0043]In terms of mass percentage, mix dried 10% polyethersulfone, 2% polyvinylpyrrolidone and 86% N,N-dimethylacetamide, heat to 60°C to dissolve and stir for about 6 hours, then add 1% Polyethyleneimine (10000) and 1% glycerol glycidyl ether were reacted at 60°C for 2 hours, and left to stand for 8 hours to remove the bubbles in the feed solution to prepare a film solution.

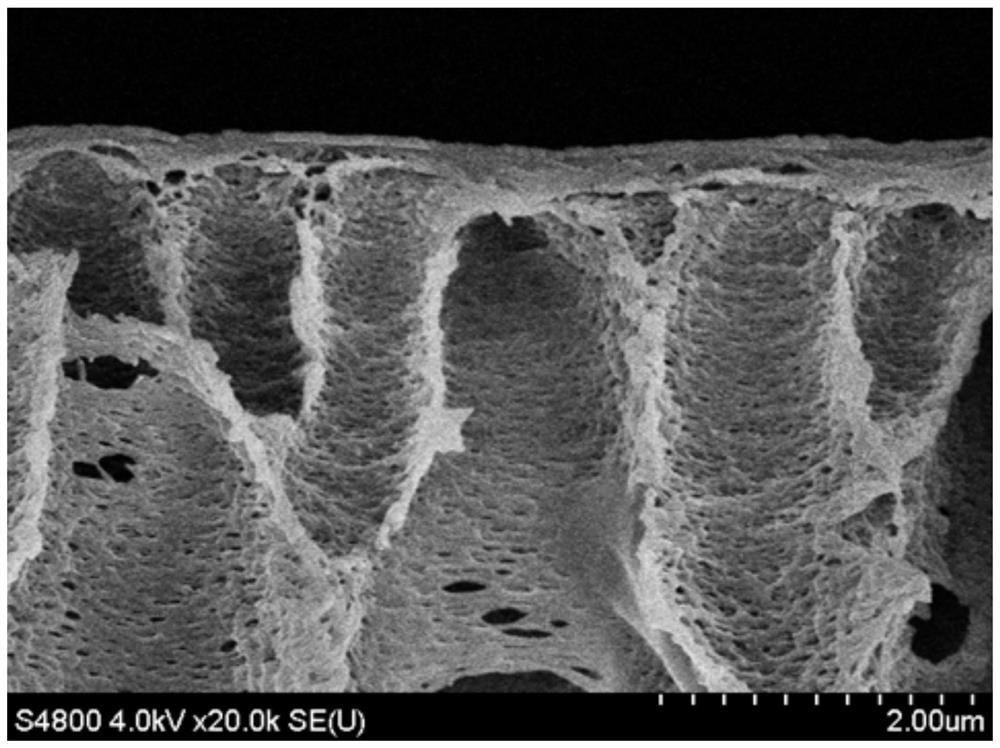

[0044] Ultrafiltration support layer: put the above membrane solution into the ultrafiltration membrane scraping equipment, adjust the parameters of the scraping membrane, and obtain an ultrafiltration support layer with a pore size of 10nm and a thickness of 200μm. Refer to the photomicrograph figure 1 .

[0045] 2. Electrostatic spray deposition film separation layer

[0046] Active monomer solution preparation

[0047] Dissolve 0.25% polyethyleneimine PEI 70000 in 99.75% deionized water and stir to make a uniform polyethyleneimine PEI...

Embodiment 2

[0064] 1. Preparation of heavy metal adsorption support layer

[0065] In terms of mass percentage, mix dried 10% polyethersulfone, 2% polyvinylpyrrolidone and 86% N,N-dimethylacetamide, heat to 60°C to dissolve and stir for about 6 hours, then add 1% Polyethyleneimine (10000) and 1% glycerol glycidyl ether were reacted at 60°C for 2 hours, and left to stand for 8 hours to remove the bubbles in the feed solution to prepare a film solution.

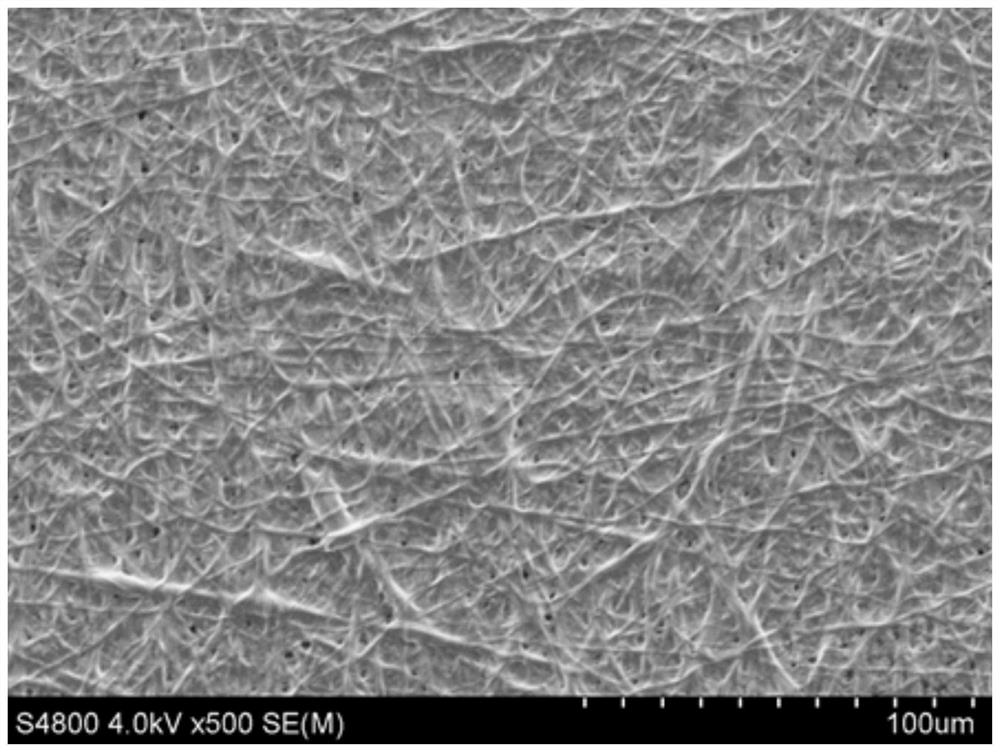

[0066] Nanofiber membrane support layer: put the above membrane solution into the electrospinning equipment, adjust the electrostatic parameters, the flow rate of the syringe pump is fixed at 50 μL / min, the distance between the needle and the collector is 10cm, and the applied voltage is 11KV. The rotating speed is 100rpm, and the dense nanofiber film is collected on the non-woven fabric, and the diameter of the nanofiber is between 150-450nm. Nanofiber Membrane Support Layer Photomicrograph Reference figure 2 .

[0067] 2. Electrostat...

Embodiment 3

[0077] 1. Preparation of heavy metal adsorption support layer

[0078] In terms of mass percentage, dissolve 16% polyvinylidene fluoride after drying in 71% N,N-dimethylacetamide and mix, heat to 60°C to dissolve and stir for about 6 hours, then add 10% polyethyleneimine (10000) and 3% glycerol glycidyl ether were reacted at 60°C for 2 hours, and left to stand for 8 hours to remove the bubbles in the feed solution to prepare a film solution.

[0079] Nanofiber membrane support layer: put the above membrane solution into the electrospinning equipment, adjust the electrostatic parameters, the flow rate of the syringe pump is fixed at 80 μL / min, the distance between the needle and the collector is 10cm, and the applied voltage is 19KV. The rotation speed was 100 rpm, and a dense nanofibrous film was collected on a non-woven fabric.

[0080] 1. Active monomer solution preparation

[0081] Dissolve 0.25% polyethyleneimine PEI 100000 in 99.75% deionized water and stir to make a un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com