W3Re-W25Re thermocouple material and preparation method of thermocouple

A thermocouple and alloy material technology, applied in the field of W3Re-W 25Re thermocouple material and its preparation of thermocouples, can solve the problems of reducing the temperature measurement accuracy of tungsten-rhenium thermocouples, dispersion of thermoelectric potential, large difference in temperature measurement tolerance, etc. Achieve the effect of improving the response speed of temperature measurement, increasing the rate of components, reducing splitting and brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]A W3Re-W25Re thermocouple material, including a negative electrode W25Re alloy material and a positive electrode W3Re alloy material, and the negative electrode W25Re alloy material is composed of the following components by weight percentage:

[0045] W: 74.2%; Re: 25.8%

[0046] The preparation method of negative pole W25Re alloy material comprises the following steps:

[0047] a) Weigh 1000g W powder and 500.8g NH 4 ReO 4 (Re: 347.7 grams);

[0048] b) Preparation of pre-alloyed powder: W powder, NH 4 ReO 4 , 400ml of absolute ethanol and 400±10g of Φ15~20mm balls, put it on a ball mill for ball milling, the ball milling speed is 100~200r / min, and the time is 20 hours; take out the mixture, evaporate the absolute ethanol to dryness in a water bath, and grind it at 1200~1300℃H 2 Reduction under ambient conditions for 2 hours to obtain W25Re pre-alloyed powder;

[0049] c) Forming: the pre-alloyed powder is pressed into a billet of about 13mm×13mm×400mm on a 500t ...

Embodiment 2

[0058] A W3Re-W25Re thermocouple material, including a negative electrode W25Re alloy material and a positive electrode W3Re alloy material, and the positive electrode W3Re alloy material is composed of the following components by weight percentage:

[0059] W: 96.5%; Re: 3.5%;

[0060] The preparation method of cathode W3Re alloy material comprises the following steps:

[0061] a) Weigh 2000g W powder and 104.4g NH 4 ReO 4 (Re: 72.5 grams);

[0062] b) Preparation of pre-alloyed powder: W powder, NH 4 ReO 4 , 500ml of absolute ethanol and 550±10g of Φ15~20mm balls, put them on a ball mill for ball milling, the ball milling speed is 300~400r / min, and the time is 15 hours; take out the mixture, evaporate dry ethanol in a water bath, 1000~1100℃H 2 Reduction under ambient conditions for 3 hours to obtain W3Re pre-alloyed powder;

[0063] c) Forming: the pre-alloyed powder is pressed into a billet of about 13mm×13mm×400mm on a 500t hydraulic press;

[0064] d) Pre-sintering...

Embodiment 3

[0072] The positive electrode W3Re alloy material (with cobalt added) consists of the following components by weight percentage:

[0073] W: 97%; Re: 2.5%; Co: 0.5%

[0074] The preparation method of positive electrode W3Re alloy material (addition of cobalt), comprises the following steps:

[0075] a), weighing 2000 grams of W powder, 50.9 grams of Co(NO 3 ) 2 .6H 2 O (Co: 10.3 g) and 74.2 g NH 4 ReO 4 (Re: 51.5 g).

[0076] b), preparation of pre-alloyed powder: W powder, Co(NO 3 ) 2 .6H 2 O, NH 4 ReO 4 , 550ml of absolute ethanol and 600±10g of Φ15~20mm balls, put them on a ball mill for ball milling, the ball milling speed is 200~300r / min, and the time is 18 hours. 2 Reduction under the atmosphere for 2.5 hours, that is, the preparation of cobalt-containing W3Re pre-alloyed powder,

[0077] c) Forming: the pre-alloyed powder is pressed into a billet of about 13mm×13mm×400mm on a 500t hydraulic press;

[0078] d) Pre-sintering: sintering at 1300-1500°C for 3 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

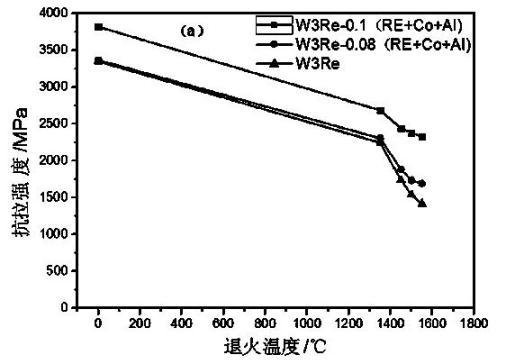

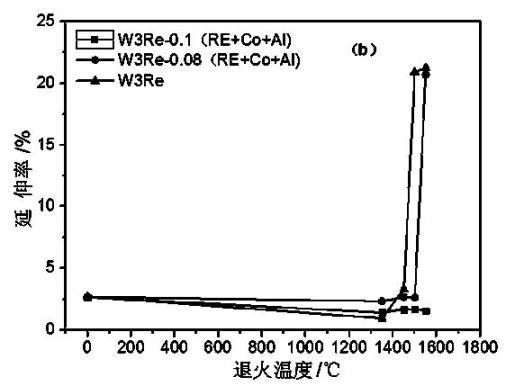

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com