Loop sensor for temperature measurement of cable conductor and method for manufacturing same

A technology of temperature sensor and cable conductor, which is applied in the direction of thermometers, thermometers, measuring devices, etc., which are directly sensitive to heat electric/magnetic components, can solve the problem of excessive cable dissection and reduction range, cable body structure and thermal field distribution. , heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

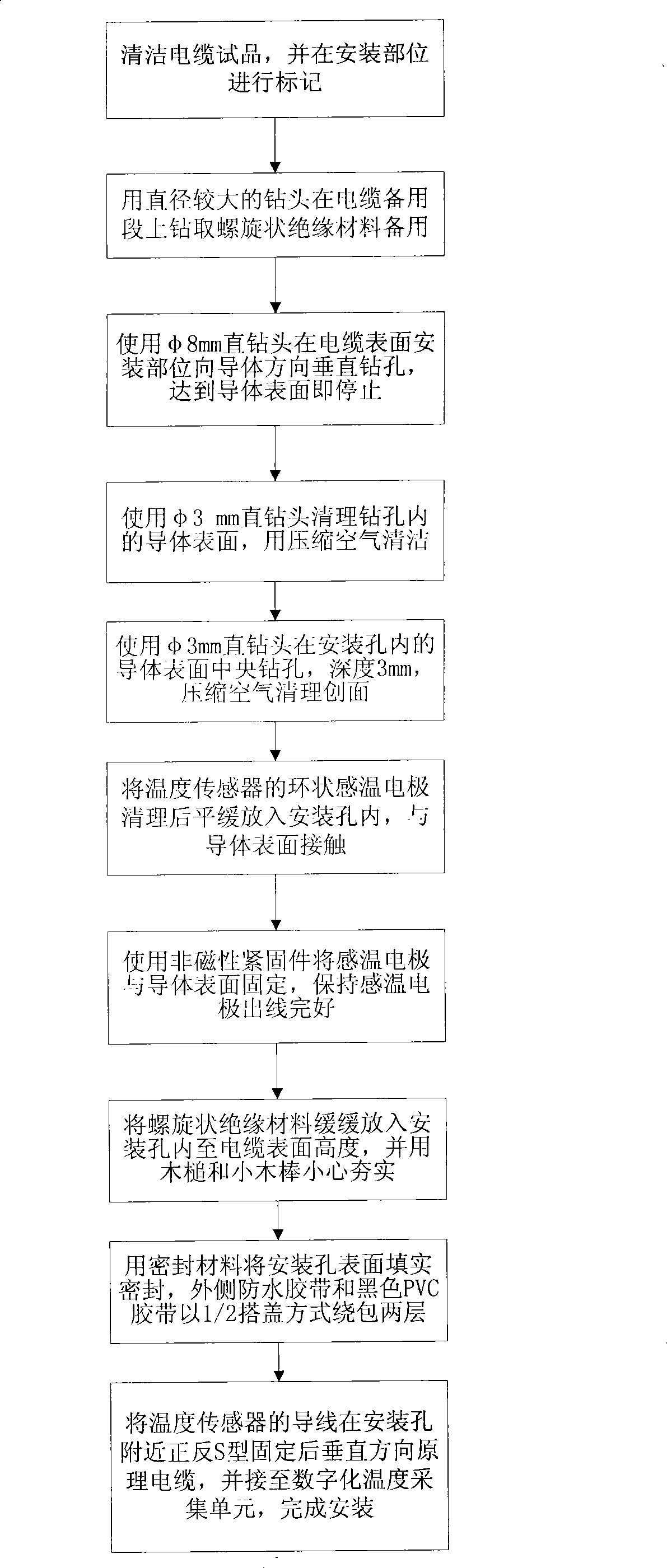

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

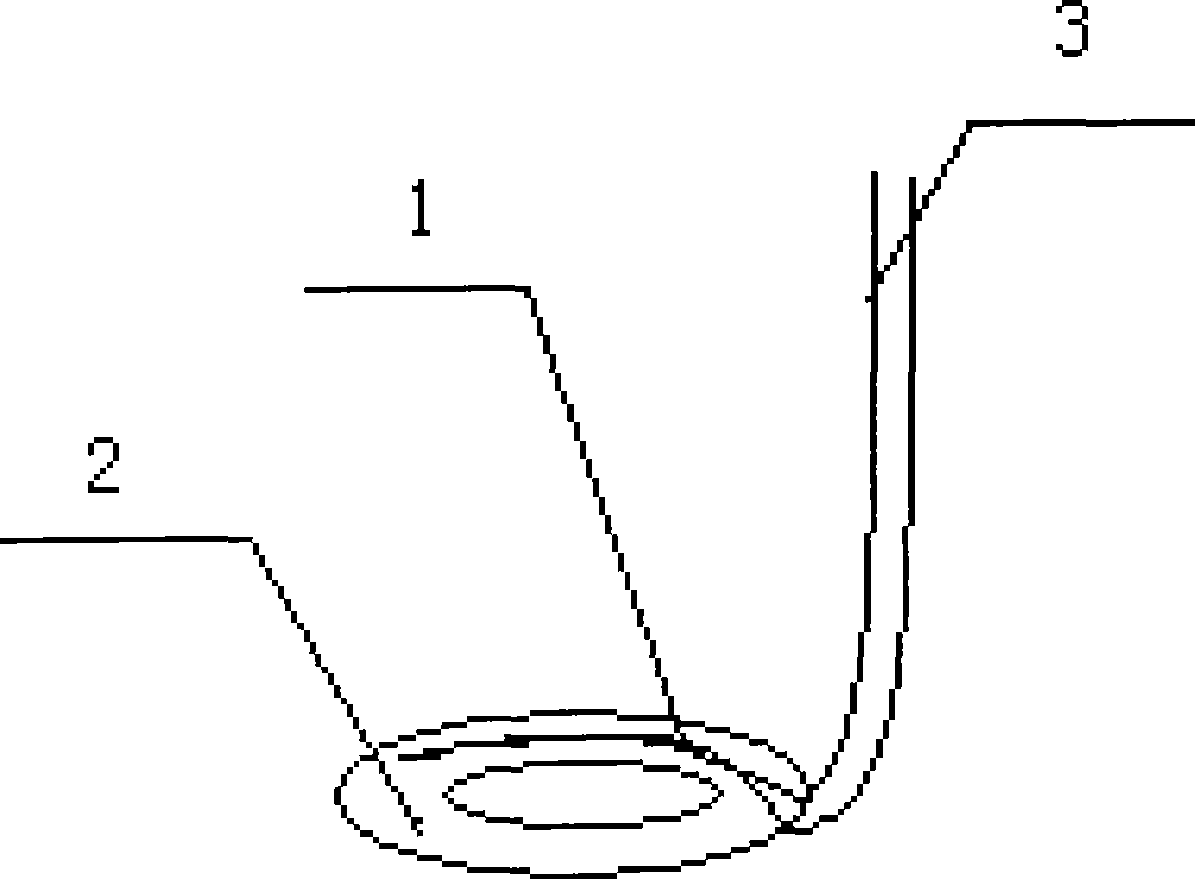

[0028] The annular sensor of the present invention is made of two thermocouple wires, the temperature-sensing ends of the thermocouple wires are in the shape of a semicircular ring with a tight spiral structure, and a copper ring gasket is welded on the temperature-sensing ends of the thermocouple wires.

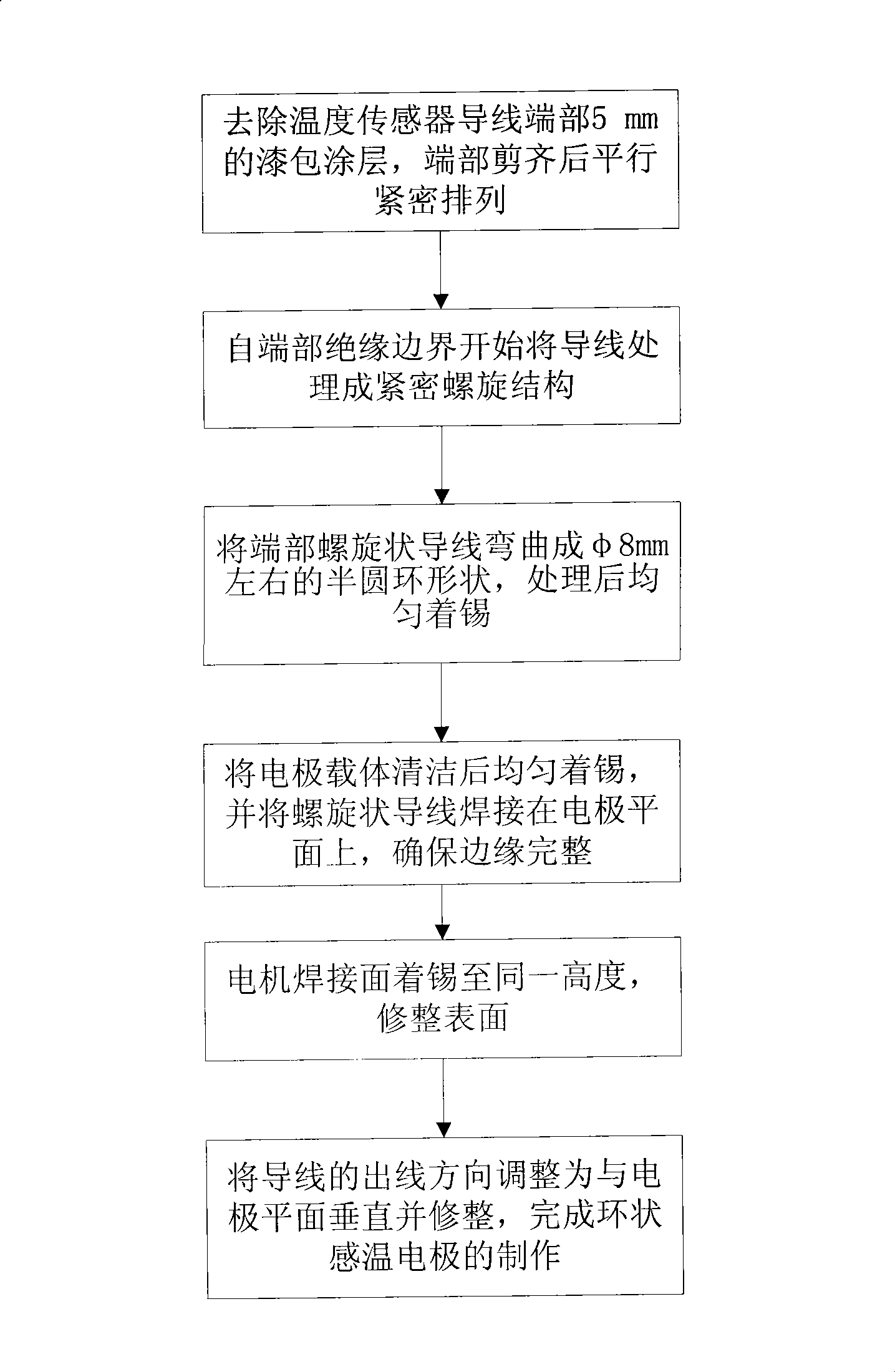

[0029] The annular sensor of the present invention adopts an industrial T-type thermocouple with a precision of 0.5 as the sensing material, and is manufactured in the following manner:

[0030] 1. The cross section is 0.5mm 2 The T-type thermocouple wire is used to make the ring-shaped temperature-sensing electrode of the sensor, and the thermocouple wire should have an enamelled coating. Remove the insulating coating on the surface of the two wire ends of the thermocouple with a length of about 5mm to 7mm, and cut the ends neatly and arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com