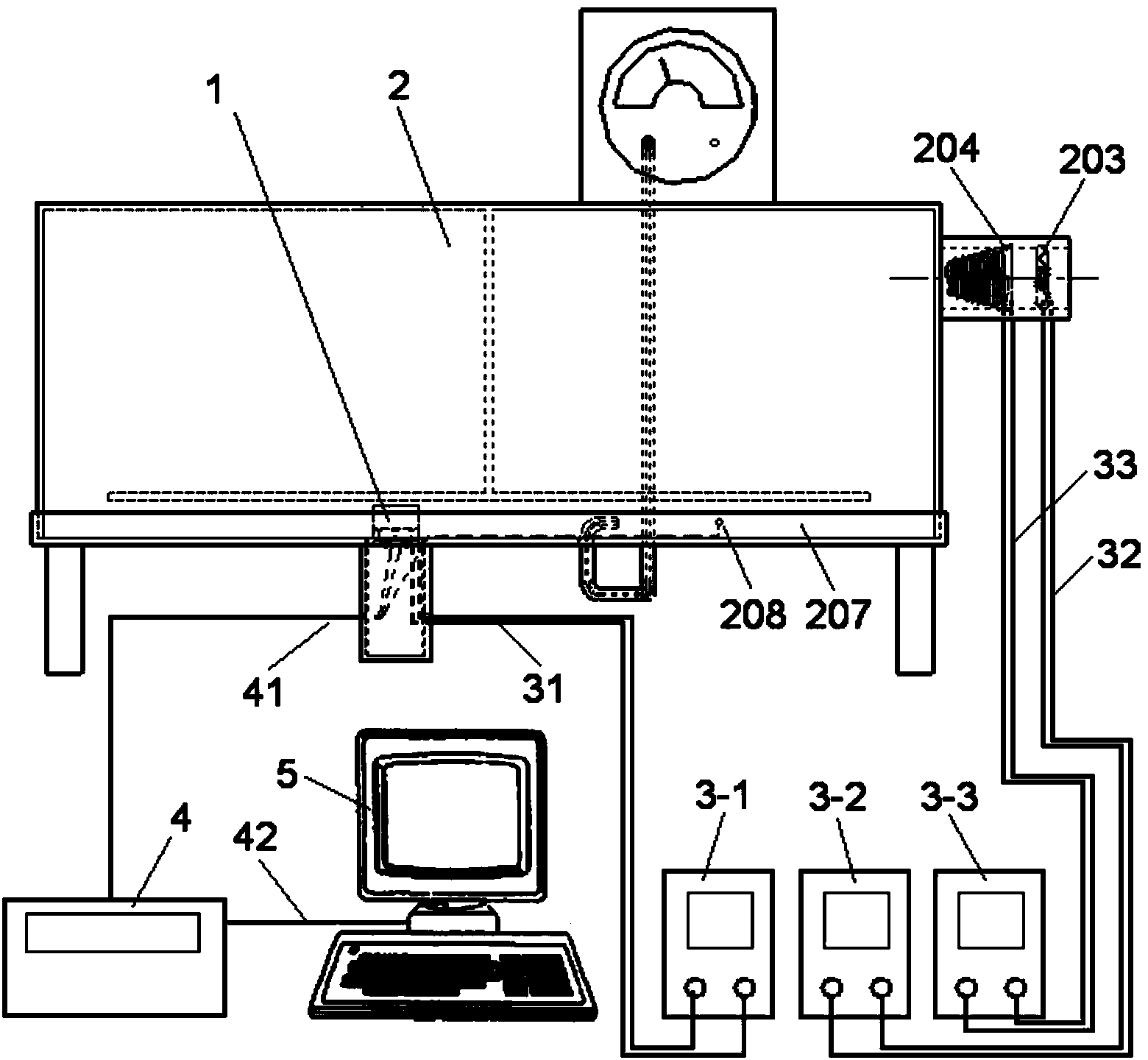

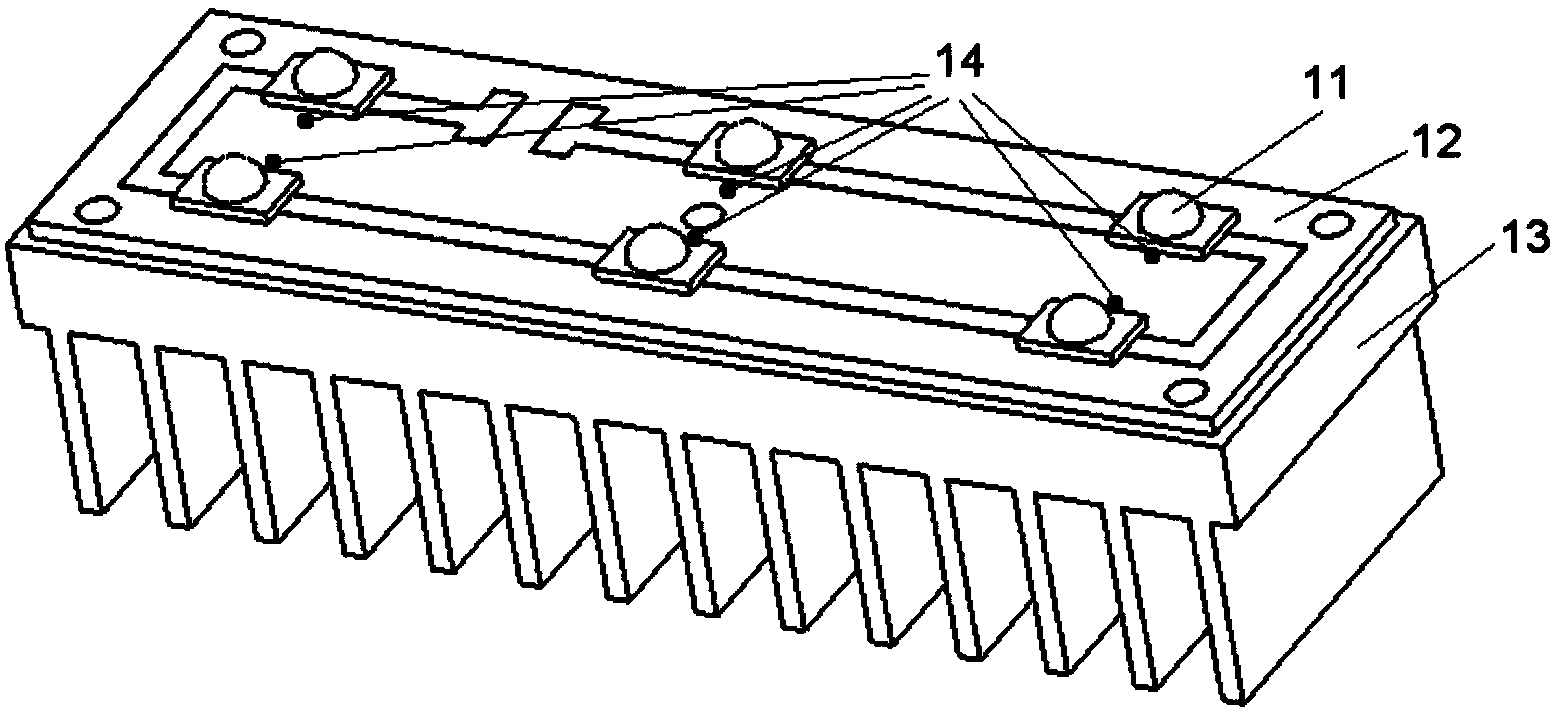

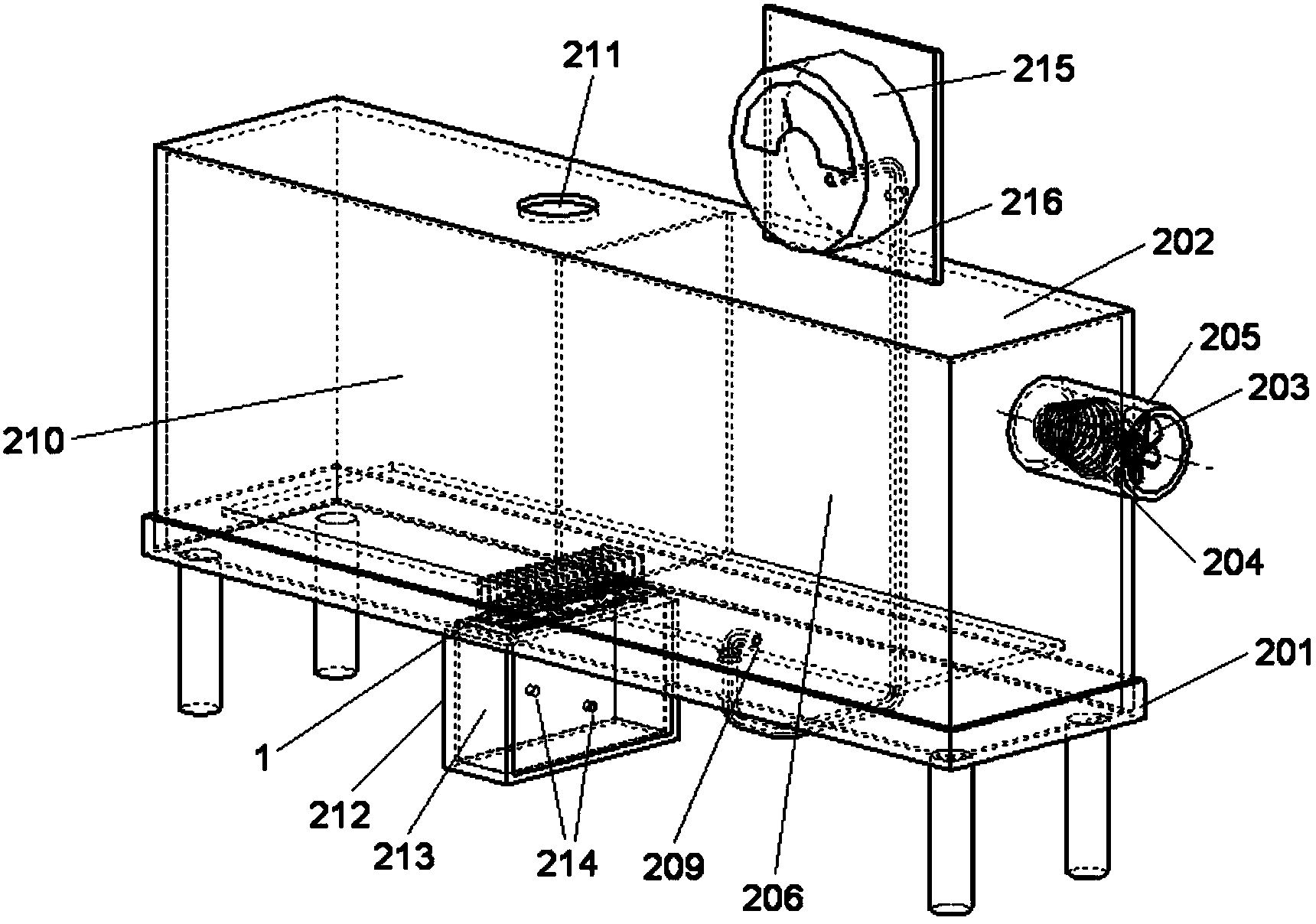

Method and system for measuring entire thermal resistance of LED (light emitting diode) radiating module

A technology of heat dissipation module and measurement method, which is applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of few test conditions and results, inconvenient analysis of trends, and large differences in working characteristics, and achieves experimental data. Effective and reliable, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] (1) Measurement of voltage temperature coefficient of LED lamp beads

[0045] Randomly extract 4 LED lamp beads that are the same as the production batch in the LED cooling module to be tested, and place them on the temperature control platform of the SSP8810-S LED Light Color Thermoelectric Performance Comprehensive Tester (hereinafter referred to as the SSP8810-S Tester). On, with a test current of 10mA, the temperature control platform was obtained at a low temperature T l and high temperature T h The forward test voltage of the LED when V l and V h , and then calculate the voltage temperature coefficient K of the LED device by formula (1). The specific data are shown in Table 1.

[0046] K = V h - V 1 T h - T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com