Method for preparing fine platinum powder used for negative electrode fine platinum wire in intensified thermocouple wires

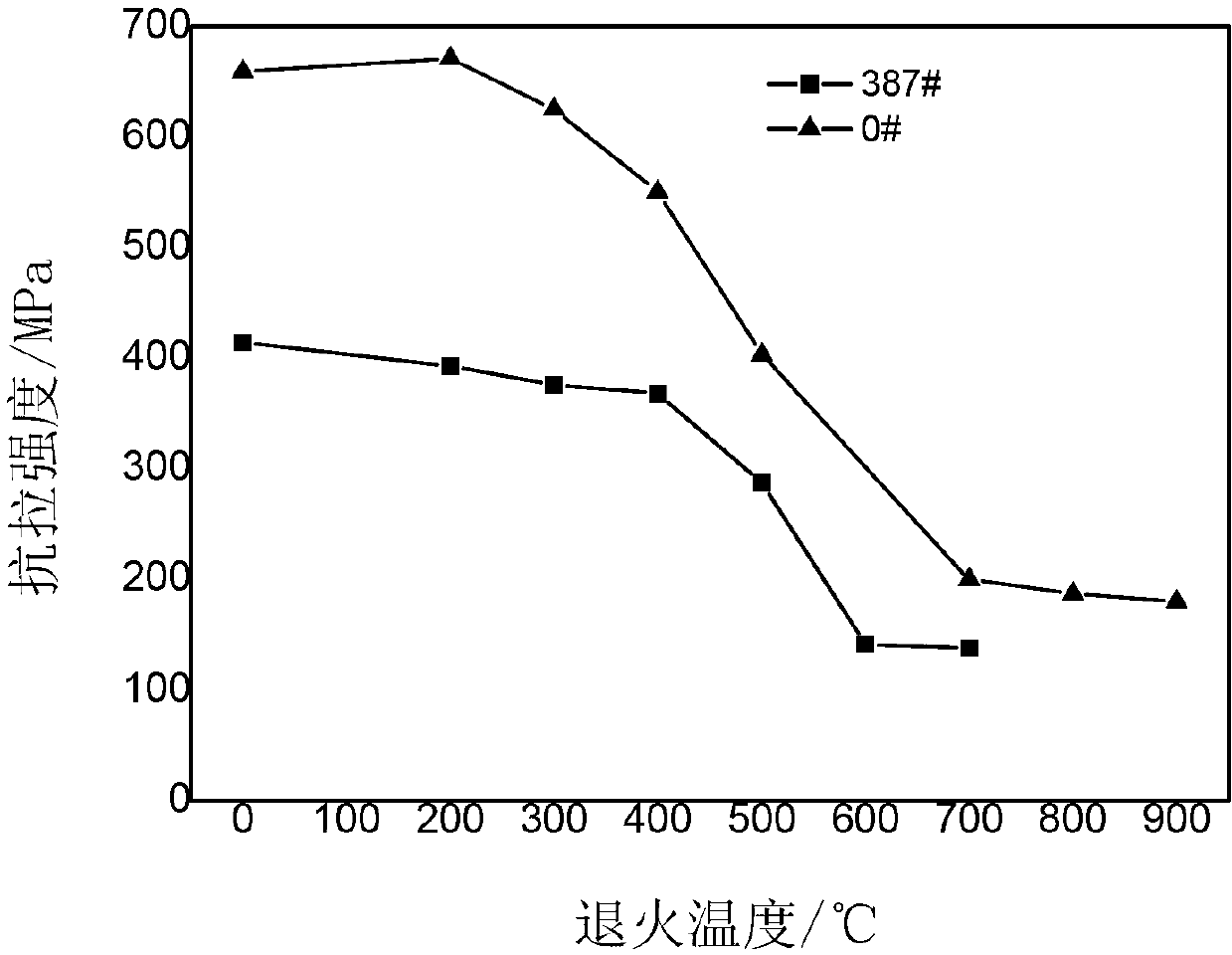

A thermocouple wire and fine technology, applied in the field of fine platinum powder preparation, can solve the problems of low tensile strength and elongation, long preparation process cycle, poor creep resistance, etc. Simple process and the effect of increasing the creep temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Platinum salt solution preparation:

[0046] Get the Pt-based material thermocouple wire waste PtRh alloy (containing rhodium3 :H 2 O=4:1:1 (volume ratio) aqua regia is heated to dissolve the PtRh alloy, concentrated to a viscous state, and 37% hydrochloric acid is added 3-5 times to decompose unreacted nitric acid to obtain a chloroplatinic acid solution. Add NaCl solid according to the ratio of PtRh:NaCl=1:0.6 (weight ratio) to obtain a crude sodium chloroplatinate solution, evaporate to dryness (control the acidity of the platinum-rhodium solution) to obtain sodium chloroplatinate particles; dissolve sodium chloroplatinate particles in water , make wherein containing platinum rhodium 50g / L, boil, adjust the pH value of solution with 10% chlor-alkali to be 8, filter, separate out green precipitate, filter, obtain filtrate;

[0047] 2) Take the filtrate described in step 1), boil it, add chlor-alkali to adjust the pH value of the solution to 8 (make the metal ions ...

Embodiment 2

[0056] 1) Preparation of platinum salt solution

[0057] Get the Pt-based material thermocouple wire waste PtRh alloy (containing rhodium3 :H 2 O=4:1:1 (volume ratio) aqua regia is heated to dissolve the PtRh alloy, concentrated to a viscous state, and 37% hydrochloric acid is added 3-5 times to decompose unreacted nitric acid to obtain a chloroplatinic acid solution. Add NaCl solid according to the ratio (weight ratio) of PtRh:NaCl=1:0.7 to obtain a crude sodium chloroplatinate solution, evaporate to dryness to obtain sodium chloroplatinate particles; dissolve the sodium chloroplatinate particles in water to make 50g / L, boiled, the pH value of solution is adjusted to 9 with 20% chlor-alkali, separates out green precipitate, filters, obtains filtrate;

[0058] 2) Take the filtrate described in step 1), boil it, add chlor-alkali to adjust the pH value of the solution to 9 (make the metal ions in the solution except platinum form hydroxide precipitates in the weak alkaline sol...

Embodiment 3

[0066] 1) Preparation of platinum salt solution

[0067] Get the Pt-based material thermocouple wire waste PtRh alloy (containing rhodium3 :H 2 O=4:1:1 (volume ratio) aqua regia is heated to dissolve the PtRh alloy, concentrated to a viscous state, and 37% hydrochloric acid is added 3-5 times to decompose unreacted nitric acid to obtain a chloroplatinic acid solution. Add NaCl solid according to the ratio (weight ratio) of PtRh:NaCl=1:0.5 to obtain a crude sodium chloroplatinate solution, evaporate to dryness to obtain sodium chloroplatinate particles; add water to dissolve the sodium chloroplatinate particles, so that 100g / L, boil, adjust the pH value of solution with 5% chlor-alkali to be 7, separate out green precipitate, filter, obtain filtrate;

[0068] 2) Take the filtrate described in step 1), boil it, add chlor-alkali to adjust the pH value of the solution to 7 (make the metal ions in the solution except platinum form hydroxide precipitates in the neutral solution), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com