Thermocouple multi-point temperature measurement device and simulated pressure reactor comprising same

A temperature measuring device and a technology for simulating pressure, which is applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problem of heat conduction errors in measurement results, limited installation space of temperature field measuring devices, and the like. Problems such as long temperature response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] While the present invention will be fully described with reference to the accompanying drawings containing preferred embodiments of the invention, it should be understood before proceeding that those skilled in the art may modify the invention described herein while obtaining the technical effects of the present invention. Therefore, it should be understood that the above description is a broad disclosure for those skilled in the art, and its content is not intended to limit the described exemplary embodiments of the present invention.

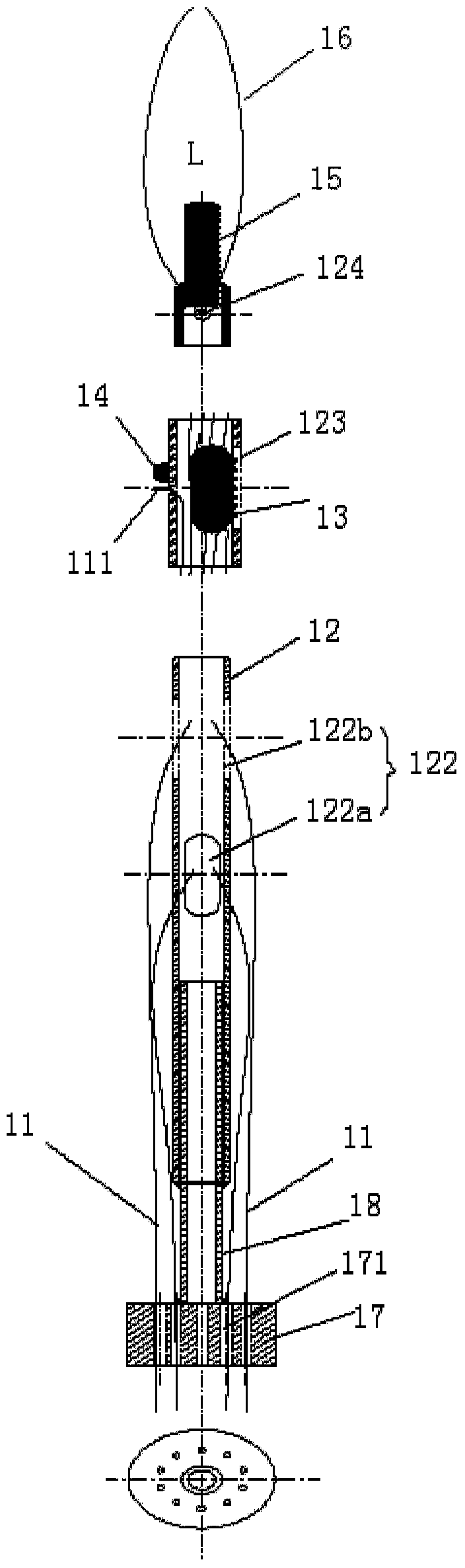

[0031] Refer below Figure 3-7 A thermocouple multi-point temperature measuring device according to an exemplary embodiment of the present invention is described.

[0032] like image 3 As shown, a thermocouple multi-point temperature measurement device 10 according to an exemplary embodiment of the present invention includes: at least two thermocouple wires 11; One end (corresponding to the upper end in the figure) and the second end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com