Metallic material tensile experiment system of multifunctional integration structure

A technology of metal materials and experimental systems, which is applied in the field of high-temperature mechanical properties research of materials, can solve problems such as the inability to provide experimental environments, and achieve the effects of reducing damage, reducing oxidation and releasing toxic gases, avoiding oxidation and releasing toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

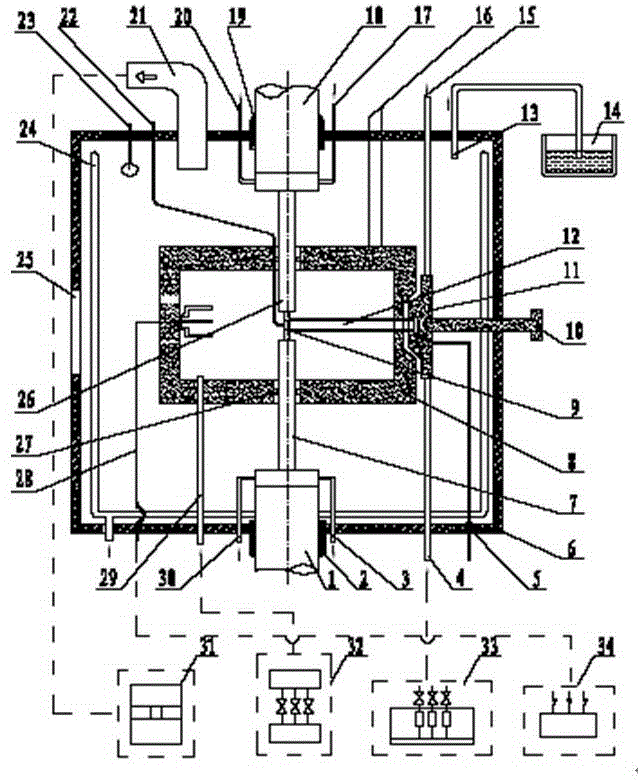

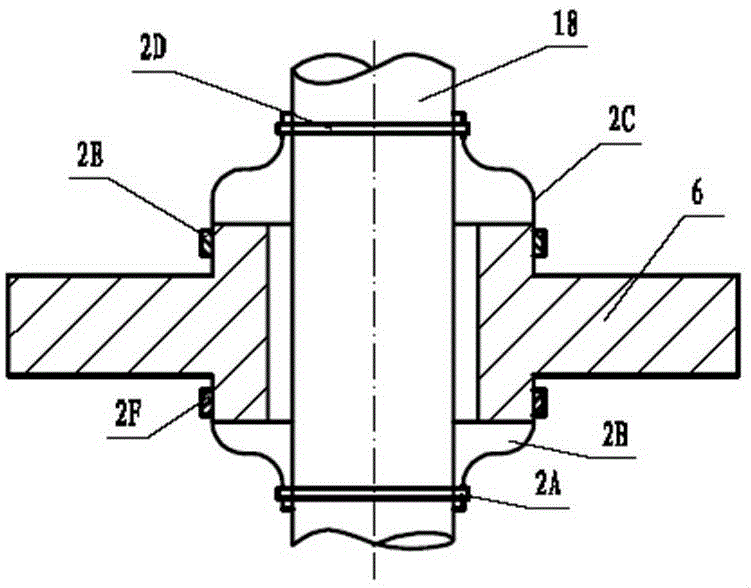

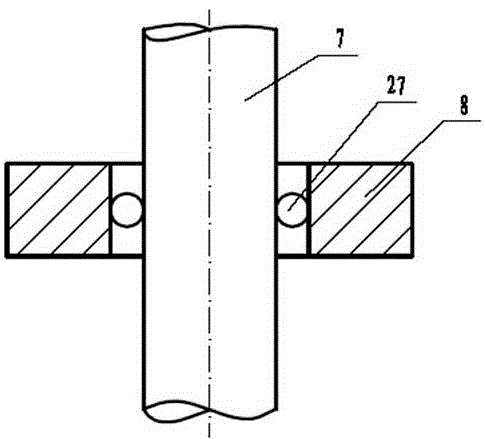

[0030] This example requires the use of figure 1Loading and measuring system, heating control system and vacuum system in the. The test piece is heated in a vacuum environment, and the tensile test is carried out when the temperature required for the test is reached. The loading system includes the upper chuck 18 of the testing machine, the lower chuck 1, the upper extension rod 26 connected to the sample, the lower extension rod 7, the cooling water inlet and outlet pipes 17 and 20 of the upper chuck, the cooling water inlet and outlet of the lower chuck Outlet water pipes 3 and 30, extensometer 12, extensometer position adjustment devices 11A, 11B and 11C, extensometer cooling water pipes 4A, 4B and outlet pipe 15, extensometer release devices 10A, 10B and 10C. The heating system includes a heating furnace 8, a high-temperature furnace semi-sealing device 27, an armored thermocouple 28 for monitoring the furnace temperature, and a thermocouple wire 22 for measuring the temp...

Embodiment 2

[0034] This example requires the use of figure 1 Loading and measuring system, heating control system, vacuum system and atmosphere protection system in the. Wherein loading and measuring system, heating control system, vacuum system are the same as embodiment 1. The atmosphere protection system is connected with exhaust gas filtering and absorbing device 14 by exhaust pipeline 13 , and inert gas inlet pipeline 30 is connected with gas source and gas distribution system (including valve, flow meter and gas distribution chamber) 32 .

[0035] After the connection and assembly of the above-mentioned parts are completed, turn on the light 23 and confirm whether the extensometer 12 meets the test requirements through the observation window. If it is slow enough, you can enter the next step. If not, you need to re-adjust the extensometer in the direction of 11B and 11C s position. Then close the gas source that contains valve, flowmeter and gas distribution chamber and the valve ...

Embodiment 3

[0037] This example requires the use of figure 1 Loading and measuring system, heating control system, vacuum system and atmosphere protection system in the. When starting the gas source and gas distribution system 32 including valves, flowmeters and gas distribution chambers, it is necessary to open one of the valves or the other four groups of valves according to the requirements of the test environment. The gas distribution chamber of the gas system, and keep each group of gas flow constant, then open the valve of the intake line 30 and charge the mixed gas in the heating furnace 8. other operations with Reality Example 2 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com