Food processing machine with electric sucking pump and method for vacuumizing to produce foodstuff liquid

A technology of food processor and air pump, which can be used in household appliances, applications, kitchen appliances, etc., and can solve problems such as unsealed lids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention is further described below in conjunction with the examples.

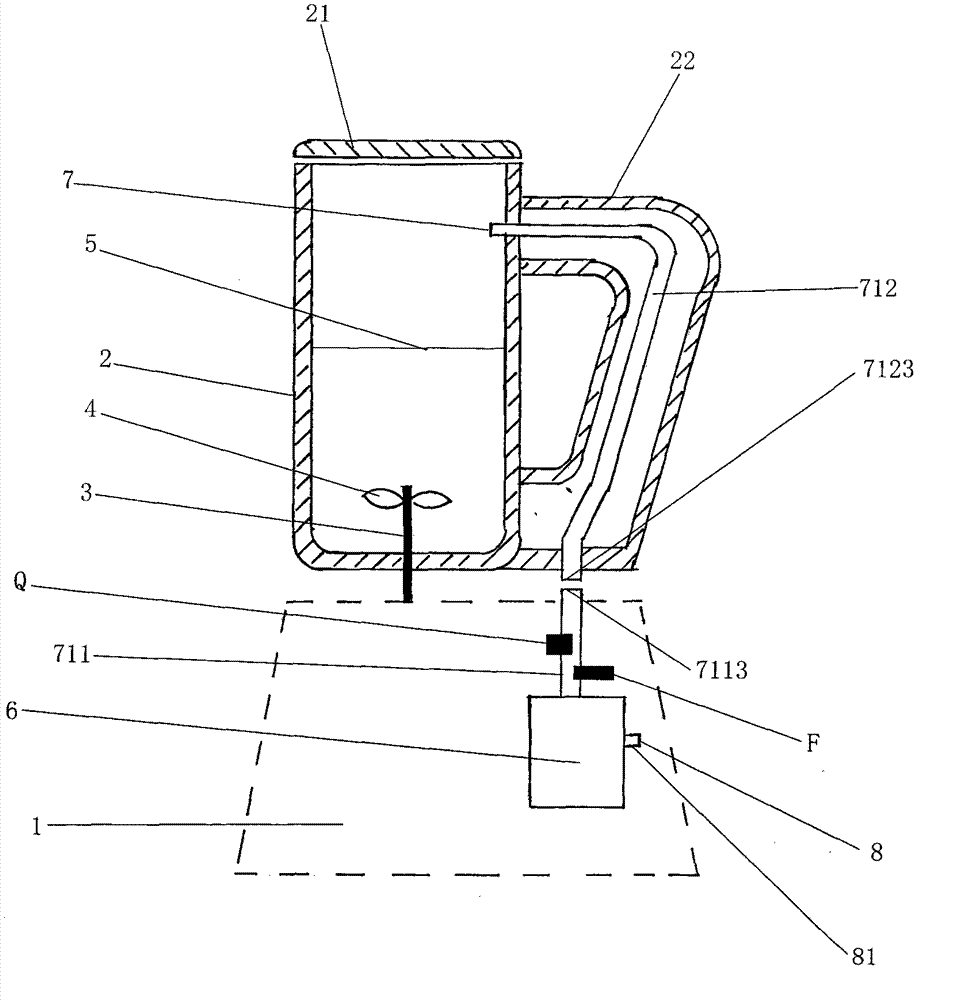

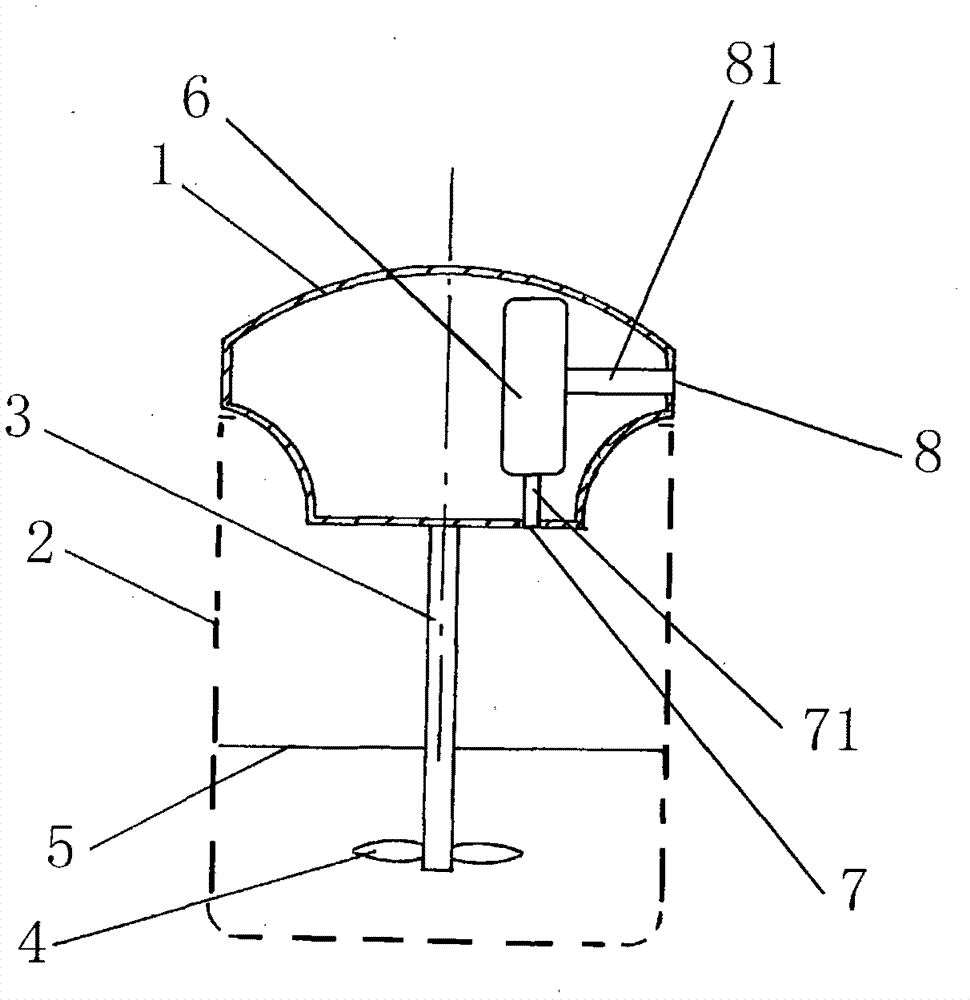

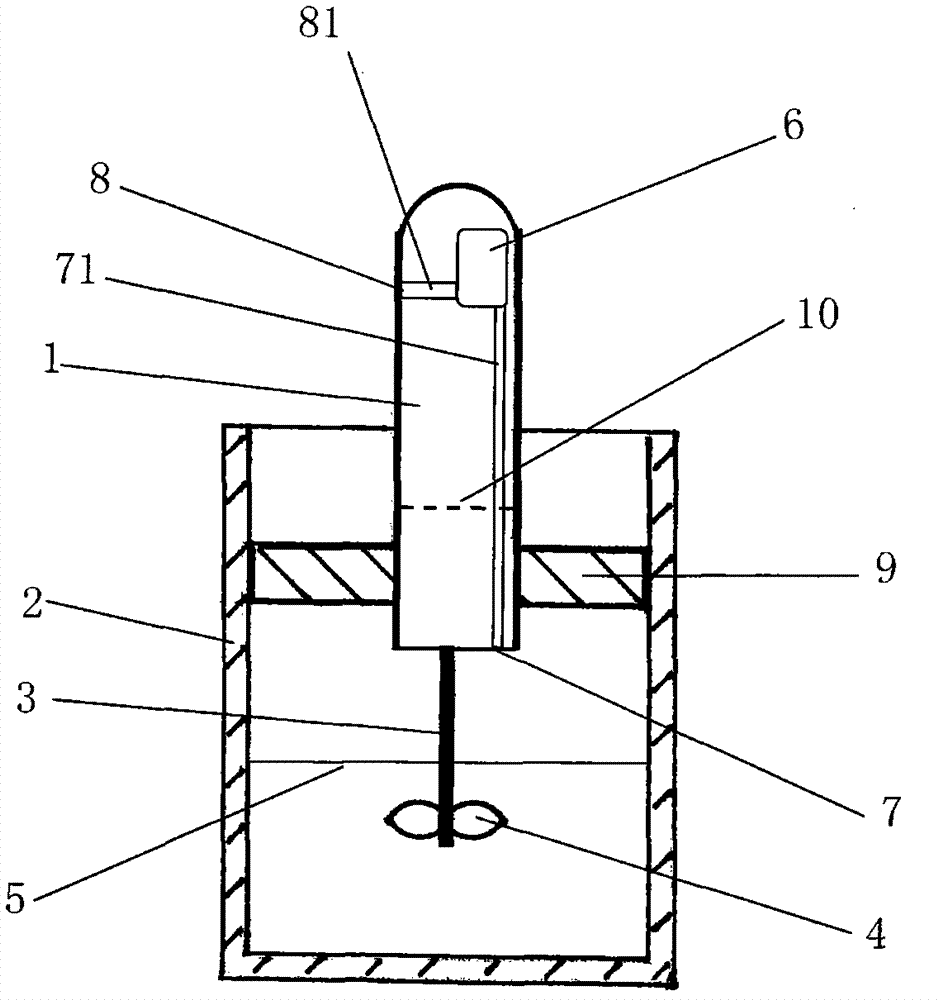

[0078] As shown in the figure, machine base (head) 1; barrel body 2; cutter shaft 3; cutter 4; food liquid surface 5; electric air pump 6; air inlet 7; exhaust port 8; piston type sealing device 9; interface 10; sealing cover 21; bucket handle 22; sealing lower cover 211; sealing upper cover 212; shaft hole 2110; cutter shaft 31; driving shaft 61; transmission belt 62; ; Suction duct 712; Suction duct 711; Suction duct joint 7113; Suction duct joint 7123; Exhaust duct 81; Air pressure sensor Q; Breathing valve F; motor D; motor shaft D1; solenoid valve F.

[0079] Components irrelevant to the present invention are omitted in the accompanying drawings, such as the most common component of the food processor, the control circuit board, and the like.

[0080] The food liquid is a mixture of food (such as fruits and vegetables) and water (or oil). The comminution knife device is only ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com