Testing method of baking temperature of steel ladle

A technology of baking temperature and testing method, which is applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve the problems that the baking temperature of the inner wall of the ladle cannot be accurately reflected, and the temperature of the inner wall is difficult, etc. Achieve convenient control and adjustment, avoid measurement errors, and display complete results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

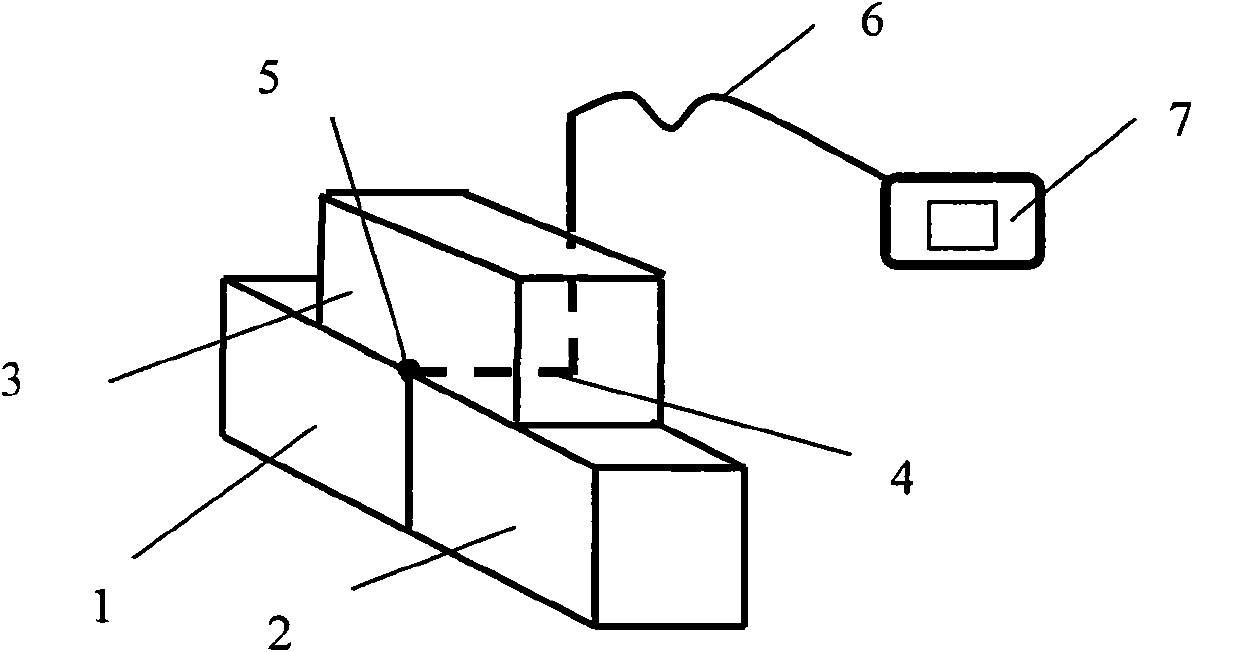

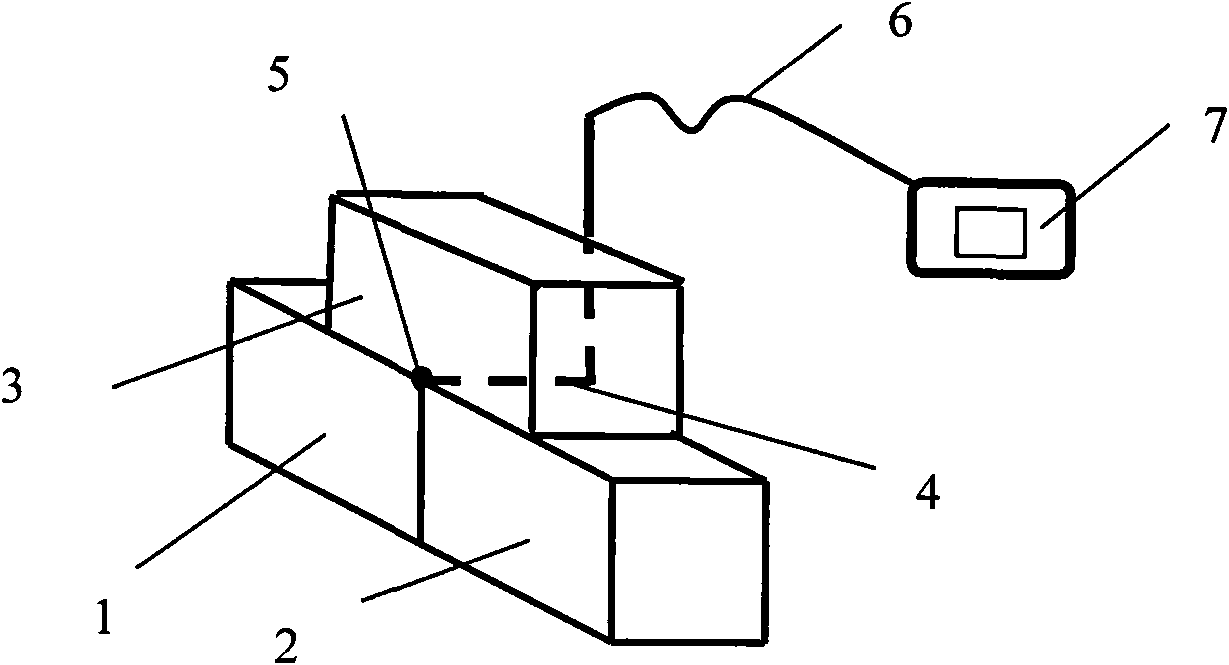

[0009] Take the 210-ton steel ladle in a steelmaking plant of an iron and steel company as an example. The shape of the ladle is similar to a cylinder, with an upper diameter of about 5 meters, a lower diameter of about 4 meters, and a height of 5 meters. Select the test points according to the shape and volume of the ladle, and select 5 thermocouples with a length of 6 meters and a diameter of 2mm. When the ladle is building the working layer, the thermocouples are respectively embedded in the center of the ladle bottom, the outer side of the ladle bottom, the lower part of the ladle wall, and the ladle wall. In the middle, slag line, etc., the temperature measurement point is located at the joint of refractory bricks and inward, the thermocouple is wired along the working layer and the permanent layer, and the tail wire is led out of the ladle.

[0010] After the masonry is completed, the ladle is placed on the roaster platform, and the thermocouple wire is connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com