A high-strength room-temperature fast-curing two-component epoxy structural adhesive

A structural adhesive and rapid curing technology, which is applied in the direction of epoxy resin adhesive, adhesive, adhesive additive, etc., can solve the problems of voids and bulges, insufficient reaction between curing agent and resin, and delamination of composite sandwich panels, etc. Problems, to achieve the effect of reducing the probability of voids and delamination, good wetting effect and bonding ability, and ensuring the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

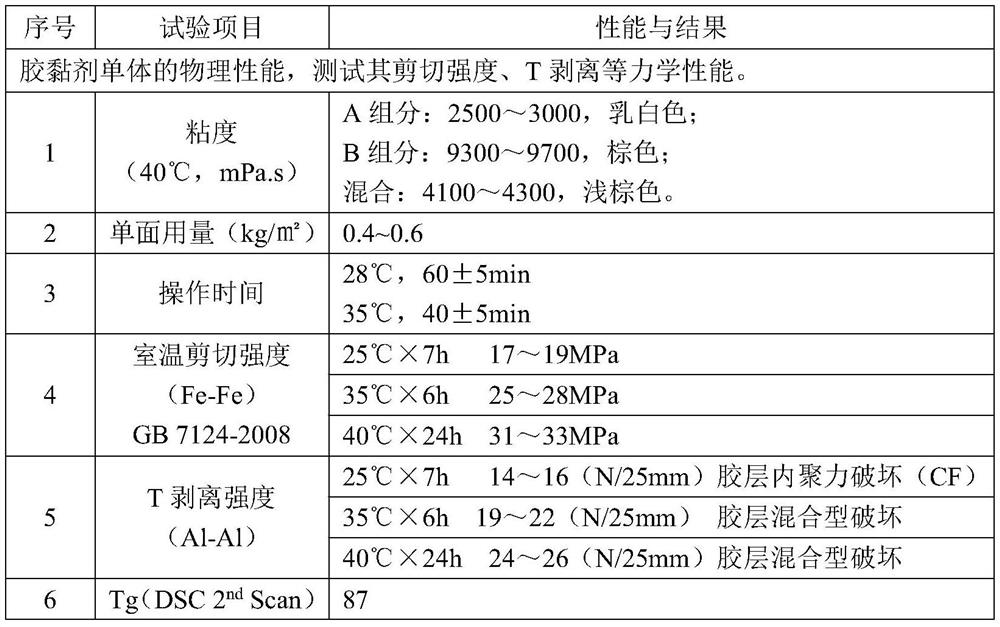

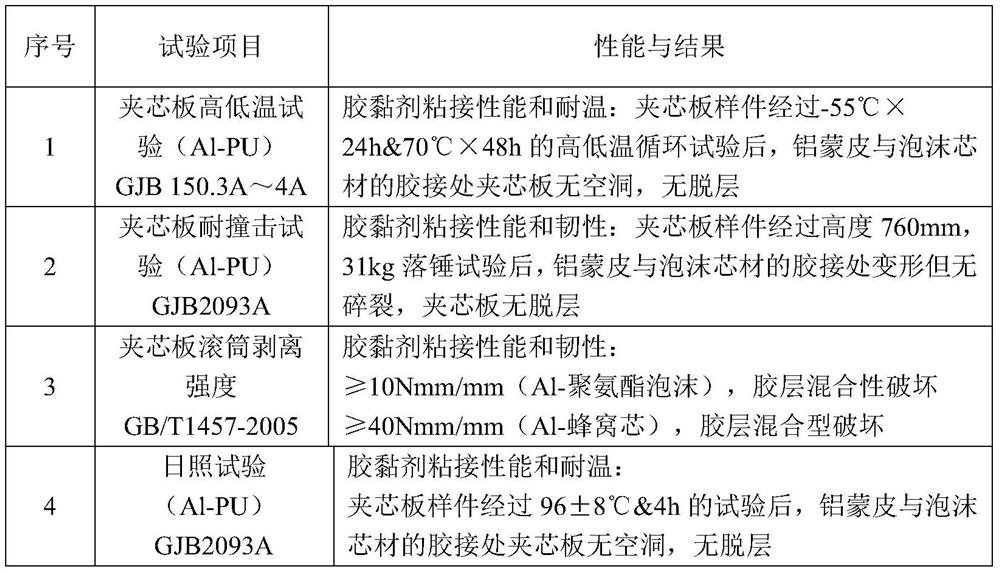

Examples

Embodiment 1

[0040] Preparation of component A: 100 parts by weight of bisphenol A epoxy resin NPEL-128, 2 parts by weight of epoxy coupling agent KH561, 10 parts by weight of 120 mesh barium sulfate whiskers, and stir evenly at room temperature;

[0041] Preparation of component B: 60 parts by weight of modified polyamide curing agent V140, 10 parts by weight of modified fatty amine curing agent JH5473, 20 parts by weight of modified fatty amine curing agent B-X, 15 parts by weight of liquid nitrile rubber, bisamino 3 parts by weight of joint agent KH791, 10 parts by weight of 120 mesh barium sulfate whiskers, stirred evenly at room temperature;

[0042] Stir components A and B evenly according to the weight ratio of 100:50 to obtain a light brown adhesive.

Embodiment 2

[0044] Preparation of component A: 110 parts by weight of bisphenol A epoxy resin E-331, 2.5 parts by weight of epoxy coupling agent KH562, 20 parts by weight of 1000 mesh silicon powder, and stir evenly at room temperature;

[0045] Preparation of component B: 50 parts by weight of modified polyamide curing agent Aek3140a, 15 parts by weight of modified fatty amine curing agent JH547315 parts by weight, 10 parts by weight of modified fatty amine curing agent V-I70, 11 parts by weight of liquid nitrile rubber, diamino 2 parts by weight of coupling agent KH602, 20 parts by weight of 1200 mesh silica powder, stirred evenly at room temperature;

[0046] Stir components A and B evenly according to the weight ratio of 100:45 to obtain a light brown adhesive.

Embodiment 3

[0048] Preparation of component A: 120 parts by weight of bisphenol A epoxy resin NPEL-128, 4 parts by weight of epoxy coupling agent KBM403, 30 parts by weight of 5000 mesh silicon powder, and stir evenly at room temperature;

[0049] Preparation of component B: 80 parts by weight of modified polyamide curing agent V140, 25 parts by weight of modified fatty amine curing agent JH5432s, 15 parts by weight of modified fatty amine curing agent B-X, 15 parts by weight of modified fatty amine curing agent V-I70 Part, 25 parts by weight of liquid nitrile rubber, 4 parts by weight of double amino coupling agent KBM603, 30 parts by weight of 5000 mesh silicon micropowder, stir at room temperature;

[0050] Stir components A and B evenly according to the weight ratio of 100:40 to obtain a light brown adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com