Layer-by-layer brush coating preparation method of thin film

A technique of brushing and filming, applied in the field of layer-by-layer brushing and preparation of films, can solve the problems of being easily affected by the external environment temperature, wasting solution, and difficult to obtain a film with a smooth and uniform surface. Adjust, save solution, improve the effect of uneven thickness of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

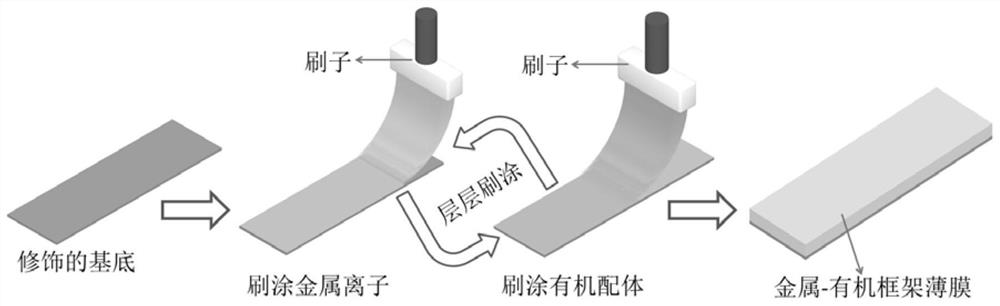

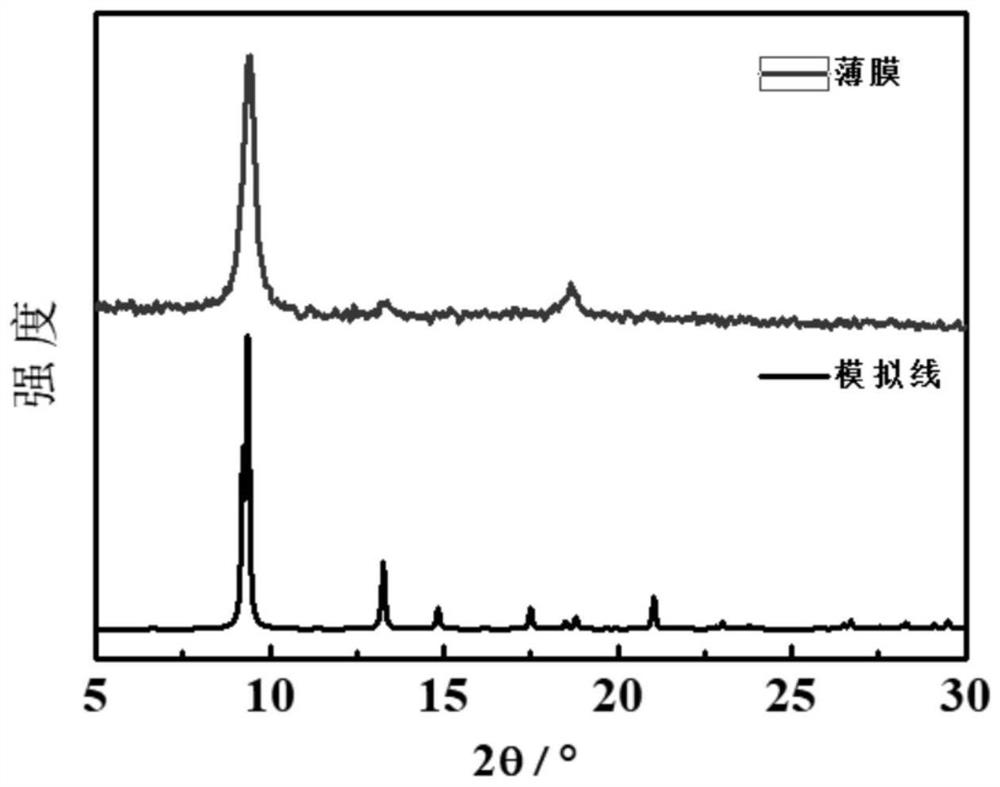

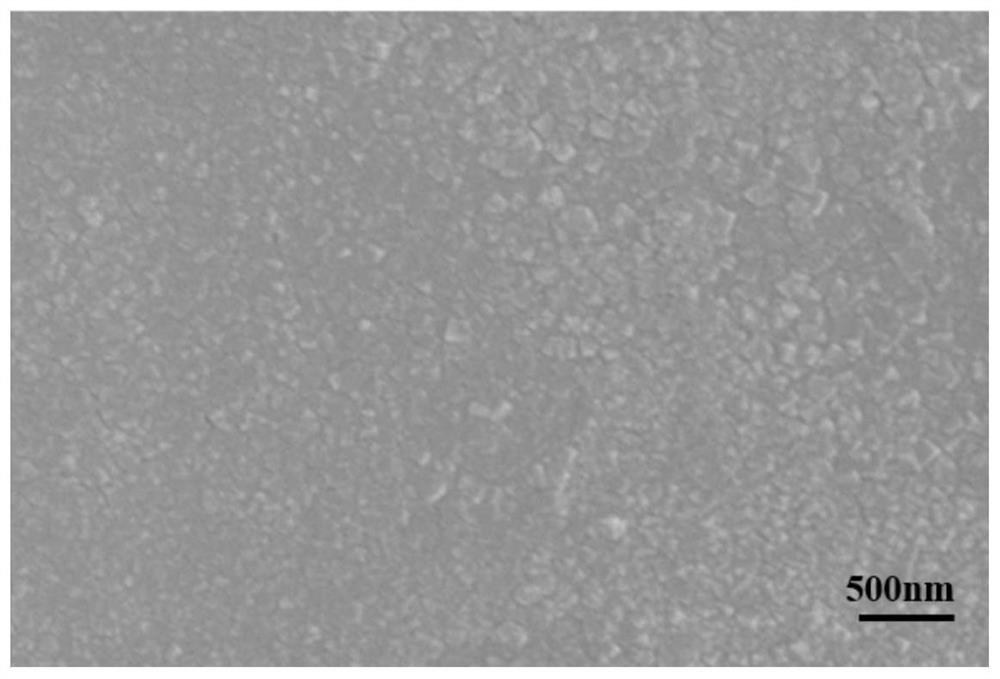

[0039] basically as figure 1 The preparation process of the metal-organic framework film shown, the preparation of the metal-organic framework (in MOFCu 2 Dcam 2dabco as an example) of self-assembled films, the tools used in the preparation process are arranged according to the laboratory arrangement, and the number of preparations is arranged according to the needs of the experiment; specifically, the following steps are included:

[0040] Weigh copper acetate, D-camphoric acid (Dcam) and 1,4-diazabicyclo[2.2.2]octane (dabco), dissolve them respectively in absolute ethanol, and prepare the concentration to be 5mmol respectively / L copper acetate ethanol solution, 5mmol / L D-camphoric acid ethanol solution and 2.5mmol / L 1,4-diazabicyclo[2.2.2]octane ethanol solution were each 50mL, another 50mL of anhydrous ethanol.

[0041] The prepared copper acetate ethanol solution, D-camphoric acid ethanol solution, 1,4-diazabicyclo[2.2.2]octane ethanol solution and absolute ethanol wer...

Embodiment 2

[0054] The metal-organic framework MOF HKUST-1 thin film is prepared by layer-by-layer brushing method. The tools used in the preparation process are arranged according to the laboratory arrangement method, and the preparation quantity is arranged according to the experimental needs; the specific steps are as follows:

[0055] Weigh copper acetate and trimesic acid (BTC), dissolve them in absolute ethanol respectively, and prepare 50 mL each of copper acetate ethanol solution with a concentration of 5 mmol / L and trimesic acid ethanol solution with a concentration of 3.33 mmol / L. , Take another 50mL absolute ethanol.

[0056] The prepared copper acetate ethanol solution, trimesic acid ethanol solution and absolute ethanol were placed in beakers respectively.

[0057] The silicon wafer modified with hydroxyl groups was selected as the growth substrate for experiments.

[0058] Finally, according to the properties of the solution and the growth of the film, determine the stop ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com