Silver electrode paste

A technology of silver electrodes and conductive pastes, applied in circuits, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as adverse effects, improve wettability, prevent flow, and overcome agglomeration and settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0034] Embodiment 1~4: a kind of silver electrode paste, described conductive paste is made up of the component of following parts by weight:

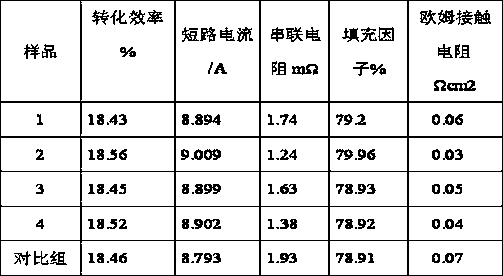

[0035] Table 1

[0036]

Example 1

Example 2

Example 3

Example 4

Silver powder 75~92 parts

78 copies

90 copies

88 copies

82 copies

5~12 parts of organic solvent

5 copies

8 servings

4.5 servings

6 servings

2~3 copies of organic carrier

3 copies

5 copies

2.6 servings

4.5 servings

Alkylphenol polyoxyethylene ether 0.5~1 part

0.7 parts

0.6 parts

0.9 parts

0.8 parts

Metal glass-ceramic powder 0.8~5.3 parts

2.8 servings

0.9 parts

3.2 parts

1 copy

[0037] ;

[0038] The above-mentioned organic carrier is formed by mixing butyl carbitol acetate, ethyl cellulose, acrylate, oleic acid, polypropylene glycol, and polyamide wax in a weight ratio of 75:7:6:4:3:5.

[0039] The above-mentioned organic carrier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com