Special composite wear-resistant rubber for inorganic enhanced driving belt and preparation method

A technology of inorganic reinforced and wear-resistant rubber, which is applied in the field of composite wear-resistant rubber for inorganic reinforced transmission belts and its preparation, can solve the problem of prolonging the service time, tensile strength and wear resistance of the special composite wear-resistant rubber for inorganic reinforced transmission belts. It can achieve the effect of obvious improvement of tensile strength, overcoming poor wear resistance and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

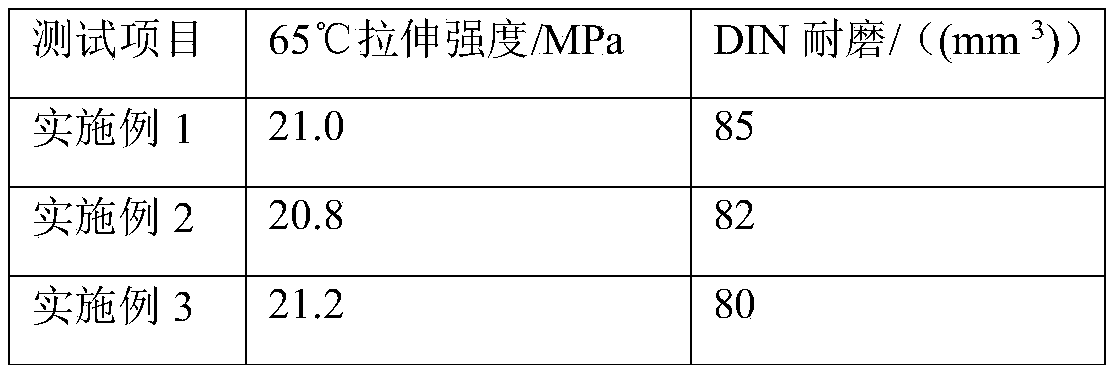

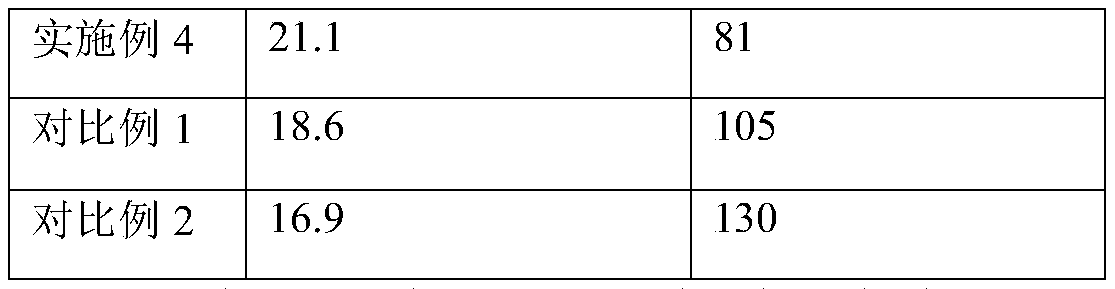

Examples

Embodiment 1

[0025] A special composite wear-resistant rubber for inorganic reinforced transmission belts. The special composite wear-resistant rubber for inorganic reinforced transmission belts includes the following components in parts by weight: 40 parts of styrene-butadiene rubber, 20 parts of butadiene rubber, and 10 parts of EPDM rubber , 15 parts of wear-resistant filler, 5 parts of sulfur, 5 parts of titanate coupling agent, 1 part of filling and reinforcing agent white carbon black, 2 parts of anti-aging agent RD, 1 part of softener aromatic oil, 1 part of vulcanization aid TBBS;

[0026] The wear-resistant filler is a layered silicate wear-resistant filler of molybdenum disulfide coated graphene.

[0027] The preparation method of the above-mentioned inorganic reinforced transmission belt special composite wear-resistant rubber comprises the following steps:

[0028] Step 1. Dissolve molybdenum chloride in ethanol, stir evenly to obtain a precursor solution, spray the precursor s...

Embodiment 2

[0032] A special composite wear-resistant rubber for inorganic reinforced transmission belts, the special composite wear-resistant rubber for inorganic reinforced transmission belts includes the following components in parts by weight: 60 parts of styrene-butadiene rubber, 30 parts of butadiene rubber, and 20 parts of EPDM rubber , 25 parts of wear-resistant filler, 8 parts of sulfur, 10 parts of titanate coupling agent, 3 parts of filling and reinforcing agent white carbon black, 3 parts of anti-aging agent RD, 2 parts of softener aromatic oil, 3 parts of vulcanization aid TBBS;

[0033] The wear-resistant filler is a layered silicate wear-resistant filler of molybdenum disulfide coated graphene.

[0034] The preparation method of the above-mentioned inorganic reinforced transmission belt special composite wear-resistant rubber comprises the following steps:

[0035] Step 1. Dissolve molybdenum chloride in ethanol, stir evenly to obtain a precursor solution, spray the precurs...

Embodiment 3

[0039] A special composite wear-resistant rubber for inorganic reinforced transmission belts. The special composite wear-resistant rubber for inorganic reinforced transmission belts includes the following components in parts by weight: 60 parts of styrene-butadiene rubber, 25 parts of butadiene rubber, and 20 parts of EPDM rubber , 22 parts of wear-resistant filler, 5 parts of sulfur, 9 parts of titanate coupling agent, 3 parts of filling and reinforcing agent white carbon black, 3 parts of anti-aging agent RD, 2 parts of softener aromatic oil, 3 parts of vulcanization aid TBBS;

[0040] The wear-resistant filler is a layered silicate wear-resistant filler of molybdenum disulfide coated graphene.

[0041] The preparation method of the above-mentioned inorganic reinforced transmission belt special composite wear-resistant rubber comprises the following steps:

[0042] Step 1. Dissolve molybdenum chloride in ethanol, stir evenly to obtain a precursor solution, spray the precurso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com