Sewage treatment method

A treatment method and sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc., can solve problems such as inability to remove ammonia nitrogen, high operating costs, waste water discharge, etc., and achieve biological toxicity Large, good treatment effect, high concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

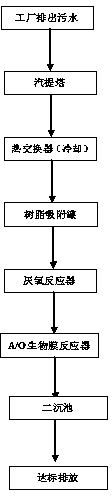

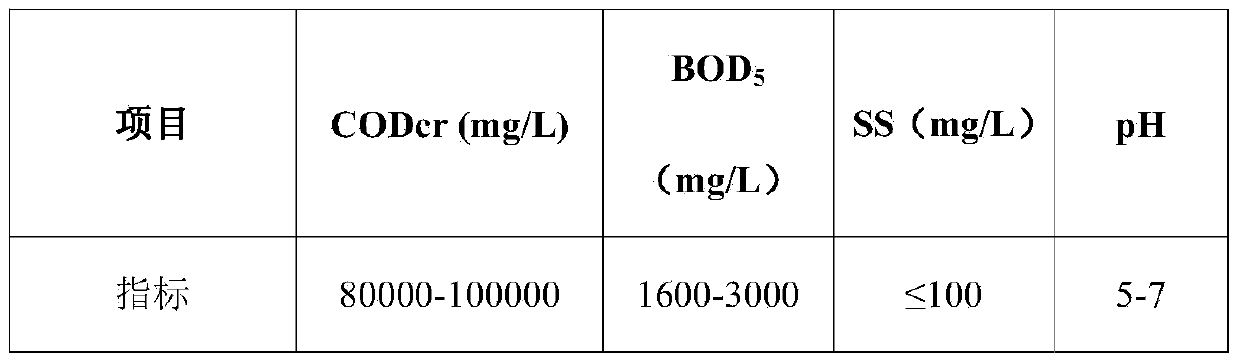

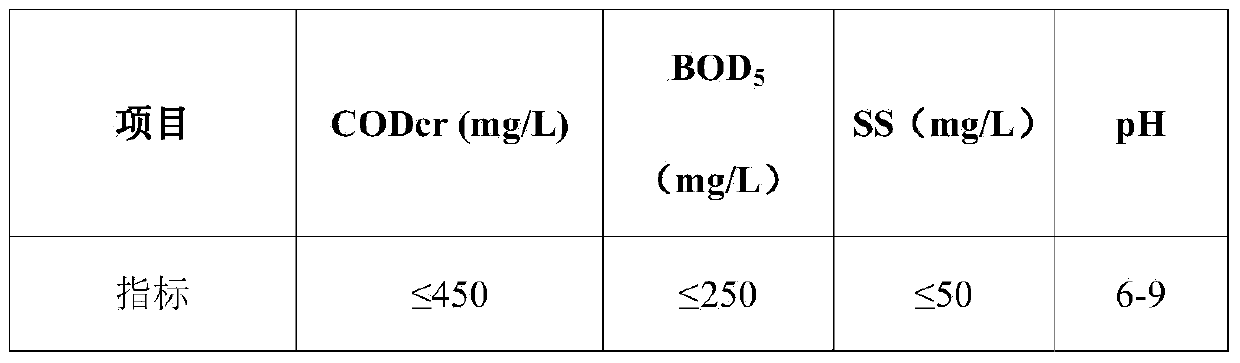

[0025] Such as figure 1 As shown, the neopentyl glycol production wastewater treatment process includes two parts: physicochemical pretreatment and biochemical treatment.

[0026] (1) Pretreatment

[0027] Due to the high concentration of trimethylamine in the high-concentration organic wastewater produced by the hydrogenation condensation method in the production process of neopentyl glycol, trimethylamine has a fishy odor and strong toxicity, and can inhibit the activity of bacteria in the wastewater, resulting in the inability of biological treatment of the wastewater. Therefore, its concentration must be reduced before biological treatment.

[0028] The first step in pretreatment is high-temperature gas stripping of wastewater. In the stripping tower, the sewage is sprayed from the top of the tower, and the steam enters from the bottom. The temperature of the discharged waste water is controlled at 95°C. Most of the organic matter such as trimethylamine in the waste wate...

Embodiment 2

[0040] A treatment method for neopentyl glycol sewage, comprising the following steps:

[0041] Step 1. Carry out high-temperature stripping of sewage, specifically, spray sewage from the top of the stripper in the stripper, and steam enters from the bottom; when performing high-temperature stripping of sewage, the temperature of the wastewater discharged from the stripper is 95°C.

[0042] Step 2, cooling the waste water discharged from step 1 to 40°C;

[0043] Step 3, pump the cooled wastewater into the resin adsorption tank for adsorption treatment; the flow rate of the wastewater in the resin adsorption tank is 10m / h, and the residence time is 20min; the resin adsorption tank is a cationic macroporous resin in the form of countercurrent regeneration Adsorption tank.

[0044] Step 4, adding a mixture of phosphate, cobalt chloride and molybdenum chloride to the wastewater after adsorption treatment, the amount added is 15mg / L, and then anaerobic biological treatment is carr...

Embodiment 3

[0054] A treatment method for neopentyl glycol sewage, comprising the following steps:

[0055] Step 1. Carry out high-temperature stripping of sewage, specifically, spray sewage from the top of the stripping tower, and steam enter from the bottom; when carrying out high-temperature stripping of sewage, the temperature of the waste water discharged from the stripping tower is 90°C.

[0056] Step 2, cooling the waste water discharged from step 1 to 30°C;

[0057] Step 3, pump the cooled wastewater into the resin adsorption tank for adsorption treatment; the flow rate of the wastewater in the resin adsorption tank is 8m / h, and the residence time is 25min; the resin adsorption tank is a cationic macroporous resin in the form of countercurrent regeneration Adsorption tank.

[0058] Step 4, adding a mixture of phosphate, cobalt chloride and molybdenum chloride to the wastewater after adsorption treatment, the amount added is 5 mg / L, and then anaerobic biological treatment is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com