MoSi2-BSG coated zirconium oxide fiberboard integrated heat insulating material and preparation method thereof

A technology of zirconia fiber and heat insulation materials, which is applied in the field of heat insulation materials preparation, and can solve problems such as harsh aerodynamic environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

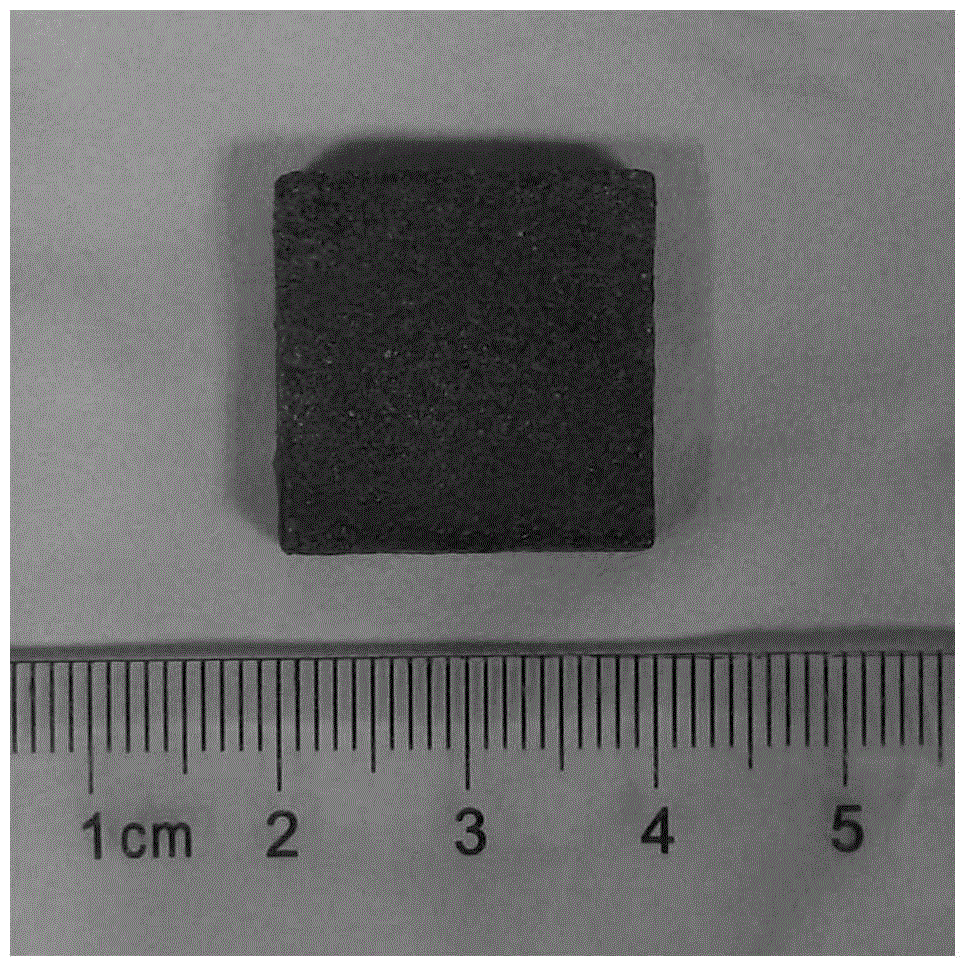

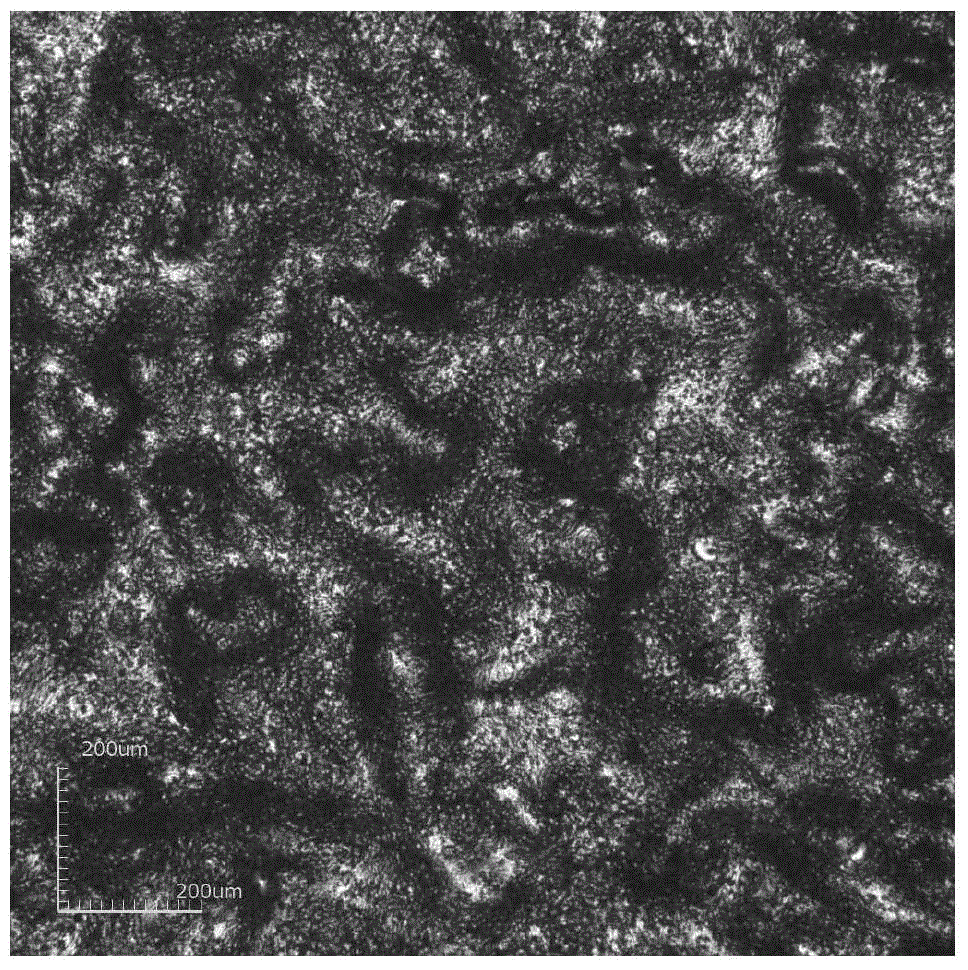

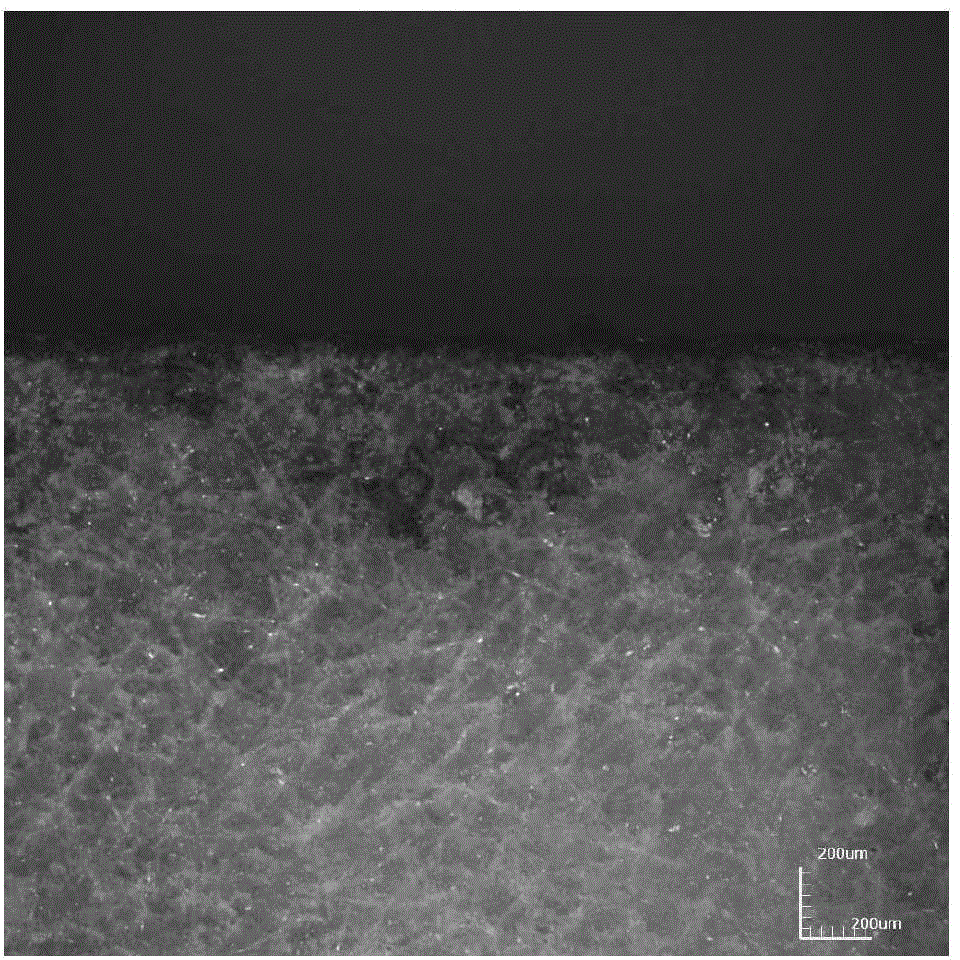

Image

Examples

example 1

[0023] (1) with silicon dioxide (SiO 2 ) and borax (Na 2 B 4 o 7 10H 2 O) is raw material, according to mass percentage: 70%, 30% weighing, the container that is equipped with mixed material is placed on the roller mill and mixes 12h, makes raw material mix evenly. Then put the mixture into a platinum crucible, keep it warm at 1450°C for 4 hours, take it out immediately, put it in water and quench it, and make a borosilicate glass frit. Use a vibrating mill to grind for 10 seconds, and crush it to borosilicate glass powder with a particle size of about 50 μm.

[0024] (2) Molybdenum disilicide (MoSi 2 ), borosilicate glass powder (BSG) as raw materials, according to the mass percentage: 20%, 80% weighing. Put the weighed raw materials into a nylon ball mill jar with ethanol as the medium, and the mass ratio of raw materials / ethanol is 1:1. A planetary ball mill was used to mill for 24 hours to obtain a slurry, wherein the particle size of the mixture was 5 μm. At the s...

example 2

[0026] (1) with silicon dioxide (SiO 2 ) and borax (Na 2 B 4 o 7 10H 2 O) is raw material, according to mass percentage: 90%, 10% weighing, the container that is equipped with mixed material is placed on the roller mill and mixes 24h, makes raw material mix evenly. Then put the mixture into a platinum crucible, keep it warm at 1550°C for 5 hours, take it out immediately, put it in water and quench it, and make a borosilicate glass frit. Use a vibrating mill to grind for 20s, and crush it to borosilicate glass powder with a particle size of about 30 μm.

[0027] (2) Molybdenum disilicide (MoSi 2 ), borosilicate glass powder (BSG) and silicon hexaboride (SiB 6 ) is raw material, according to mass percent: 40%, 57.5%, 2.5% weighing. Put the weighed raw materials into a nylon ball mill jar with ethanol as the medium, and the mass ratio of raw materials / ethanol is 1:1. A planetary ball mill was used to mill for 48 hours to obtain a slurry, wherein the particle size of the m...

example 3

[0029] (1) with silicon dioxide (SiO 2 ) and borax (Na 2 B 4 o 7 10H 2 O) is raw material, is: 85%, 15% weighing according to mass percentage, and the container that is equipped with compound is placed on the roller mill and mixes 24h, makes raw material mix evenly. Then put the mixture into a platinum crucible, keep it warm at 1500°C for 5 hours, take it out immediately, put it into water and quench it to make a borosilicate glass frit. Use a vibrating mill to grind for 15 seconds, and crush it to borosilicate glass powder with a particle size of about 40 μm.

[0030] (2) Molybdenum disilicide (MoSi 2 ), borosilicate glass powder (BSG) and silicon hexaboride (SiB 6 ) as raw material, according to mass percentage: 60%, 35%, 5% weighing. Put the weighed raw materials into a nylon ball mill jar with ethanol as the medium, wherein the mass ratio of raw materials / ethanol is 3:2. A planetary ball mill was used to mill for 36 hours to obtain a slurry, wherein the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com