Composite high-temperature molybdenum disilicide-base material and preparation method thereof

A technology of molybdenum disilicide and composite materials, which is applied in the field of high-temperature structural materials, and can solve problems such as inability to inherit Mo powder, increase process cost, and voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Prepare a high-temperature composite hollow disc with an outer diameter of 50 mm, an inner diameter of 30 mm, and a thickness of 6 mm.

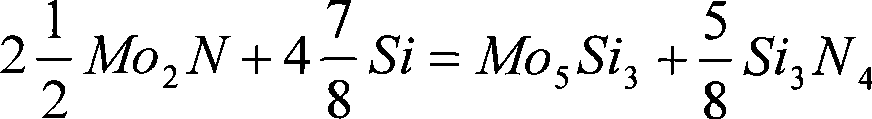

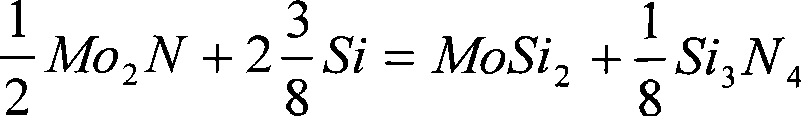

[0061] In kerosene medium, Mo with an average particle size of 1 μm 2 N powder and Si powder are evenly mixed, and the weight of Si powder is Mo 2 28% by weight of N powder. Vacuumize the reactor, then feed hydrogen to make the pressure of hydrogen in the reactor a positive pressure (the main purpose is to remove the atmospheric medium in the reactor), keep the flow of hydrogen, add the above mixed powder into the reactor, stir Powder;. The reactor was heated to 450°C at a rate of 5°C / min. HCl gas was introduced to make the concentration of HCl in the reactor 50%, and then the reactor was closed. Heating the reactor to 1050°C and keeping it warm for 5 hours, the Mo 2 Siliconization of N powder into Mo 5 Si 3 — Si 3 N 4 Composite powder, where Si 3 N 4 The volume content is about 27%.

[0062] Add the composite powder and Si...

Embodiment 2

[0066] A high-temperature composite material sheet with a length and width of 80 mm and a thickness of 1.2 mm was prepared.

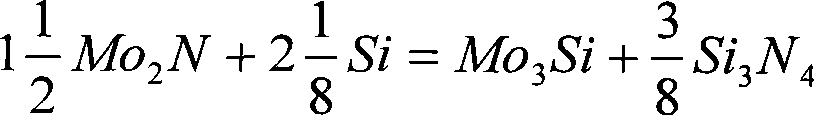

[0067] Mo with an average particle size of 0.5 microns 2 The N powder was treated three times by silicification, nitriding, and silicification to become Mo 5 Si 3 ~ Si 3 N 4 Composite powder, where Si 3 N 4 The volume content is about 54%. The first silicidation process is basically the same as that in Example 1, except that the silicidation temperature is 950° C. and the holding time is 4 hours. After the siliconization treatment, put the powder directly into the kerosene without contacting with the air. Ball mill the powder for 4 hours to eliminate agglomeration. The reactor was evacuated, and then nitrogen was introduced to make the pressure of nitrogen in the reactor a positive pressure. Keep the nitrogen flowing, add the above powder into the reactor, and stir the powder. The reactor was heated to 450°C at 5°C / min. Close the reactor and ...

Embodiment 3

[0072] Prepare a high-temperature composite material square with a side length of 20 mm and a thickness of 5 mm.

[0073] The preparation method of composite powder and mixed powder is the same as that of Example 1. YSZ powder (yttria-stabilized zirconia powder) with an average particle size of 160 microns is added as a strengthening phase, and the amount added is 20% of the weight of the mixed powder. After uniform mixing, the mixture is pressed into a blank with a side length of 26 mm and a thickness of 8.5 mm

[0074] The sintering process was carried out under nitrogen. Heating to 1300°C for 10 minutes to uniform the blank temperature, heating to 1450°C for 30 minutes for liquid phase sintering, and then heating to 1500°C for 60 minutes to nitride the remaining Si phase. The blank was molded under a nitrogen atmosphere at 1500°C to a thickness of 5.2 mm to eliminate internal pores. Machining removes the surface defect layer to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com