Experimental device and method for performing on-line monitoring on lump coal splitting decomposition

A technology of experimental device and experimental method, which can be used in measurement devices, fuel testing, material inspection products, etc., can solve problems such as hindering research development and promotion, and achieve the effect of simple device, broad application prospects, and reduced fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

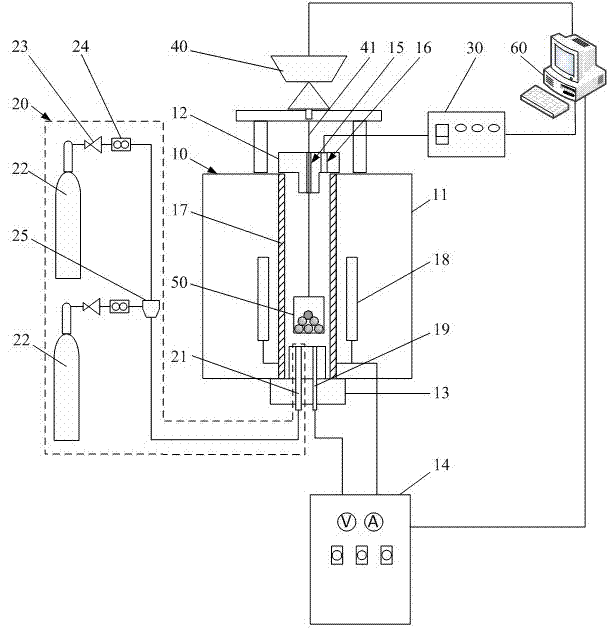

[0034] This embodiment provides an on-line monitoring experimental device for lump coal cracking. The experimental device is mainly composed of a molybdenum disilicide furnace 10, a protective gas supply device 20, a flue gas analyzer 30, an electronic balance 40, a corundum crucible 50 and a monitoring computer 60. constitute, such as figure 1 shown.

[0035]Among them, the molybdenum disilicide furnace 10 includes a furnace body and a temperature control cabinet 14; the furnace body includes a furnace body 11 and a furnace cover 12 and a furnace bottom 13 respectively arranged at the upper and lower ends of the furnace body 11; the furnace cover 12 is provided with a through hole for a hanging rope 15 and exhaust through hole 16; the furnace body 11 is mainly composed of a furnace shell, a corundum tube 17 vertically installed in the furnace shell, and some molybdenum disilicide electric heating rods 18 installed in the furnace shell and circumferentially distributed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com