Solar selectively absorbing coating and preparation method thereof

An absorbing coating and selective technology, applied in the field of solar selective absorbing coating and its preparation, medium and high temperature solar selective absorbing coating and its preparation, can solve the problems affecting the wide application and price of medium and high temperature selective absorbing coating Expensive, narrow range of refractory metal materials, etc., to achieve good thermal stability at medium and high temperatures, easy operation, and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

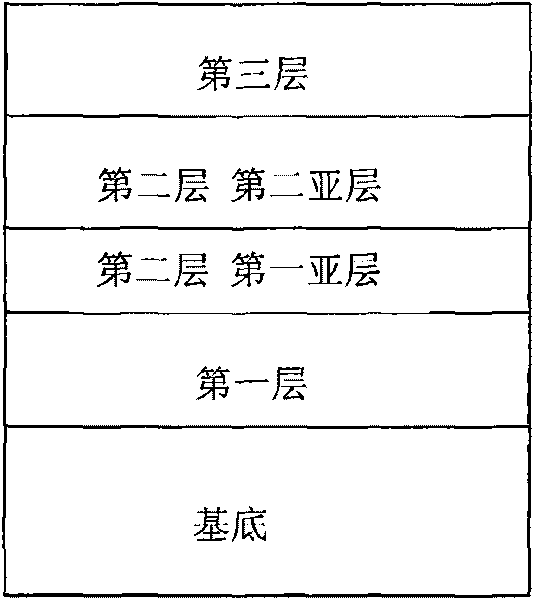

[0019] Embodiment one A kind of solar energy selective absorbing coating of the present invention, it comprises three layers: the first layer infrared reflection layer (the Cu sheet after this example adopts polishing can adopt this substrate directly as the infrared reflection layer), the second layer absorption layer, the first layer Three anti-reflection layers.

[0020] The first layer is an infrared reflective layer, which is composed of a 70nm thick Cu metal film. It is prepared by direct current sputtering of a metal Cu target with Ar gas as the sputtering gas. If the polished Cu and stainless steel sheet are used as the substrate, this can be used The substrate directly acts as an infrared reflective layer. The infrared reflective layer has high reflection characteristics to the infrared band spectrum and low emissivity.

[0021] The second layer is the absorbing layer, composed of MoSi 2 and Al 2 o 3 The structure is composed of two sub-layers with different thi...

Embodiment 2

[0028] Embodiment two : prepare a kind of solar energy selective absorbing coating, comprise three layers: the first layer infrared reflective layer (this example adopts the stainless steel plate after polishing can adopt this substrate directly as infrared reflective layer), second layer absorbing layer, the third layer Anti-reflection layer. The preparation steps are as follows:

[0029] Step 1: preparing the first infrared reflection layer. In this experiment, the polished copper sheet was selected as the substrate, because the infrared reflectivity of copper sheet and stainless steel sheet is already high, and for the sake of simplicity of the preparation process, the substrate was directly used as the infrared reflective layer. The preparation steps are the same as in Example 1.

[0030] The performance of the solar selective absorbing coating prepared in this embodiment is as follows: under the condition of air quality factor AM1.5, the absorptivity of the coating is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com