High-temperature graphite carbon bush and production method

A high-temperature graphite and production method technology, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of low impregnation weight gain, poor dispersion, poor permeability, and affecting production progress, so as to increase high-temperature oxidation resistance and resistance Abrasiveness, dense internal structure, and the effect of improving homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

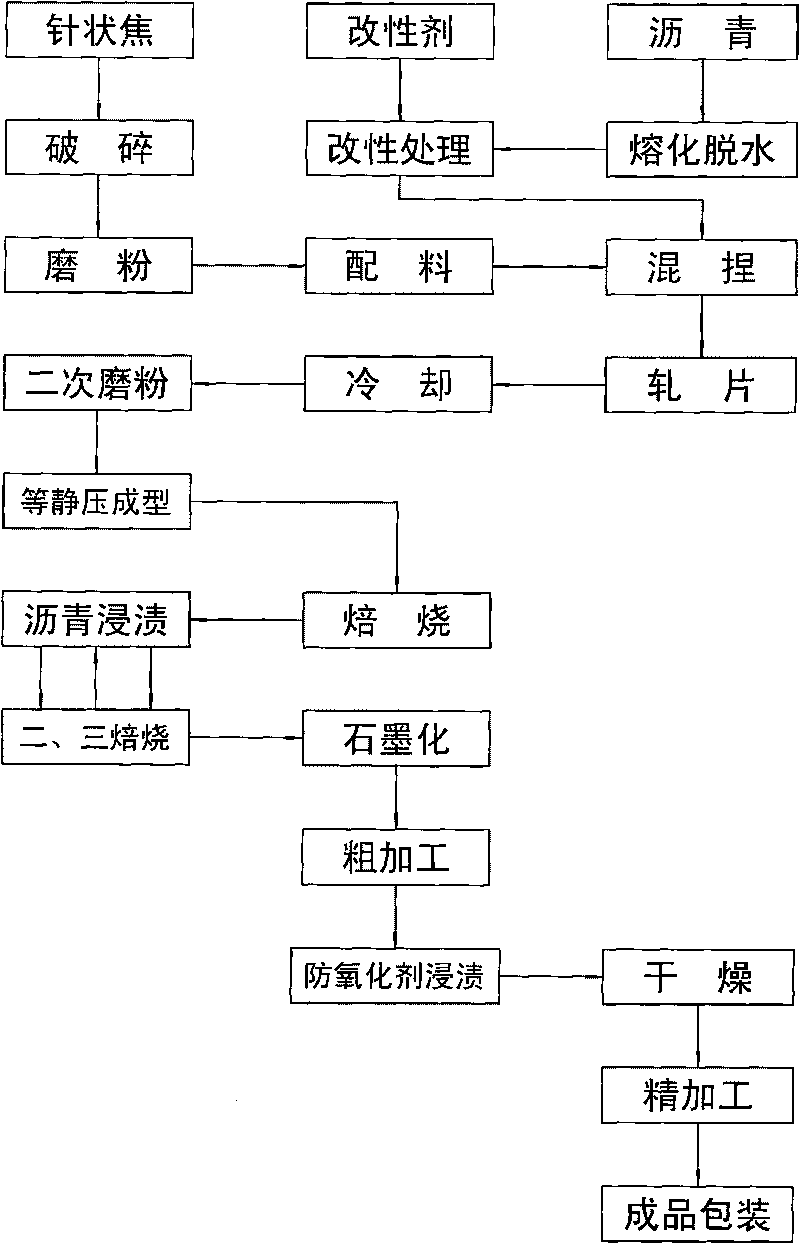

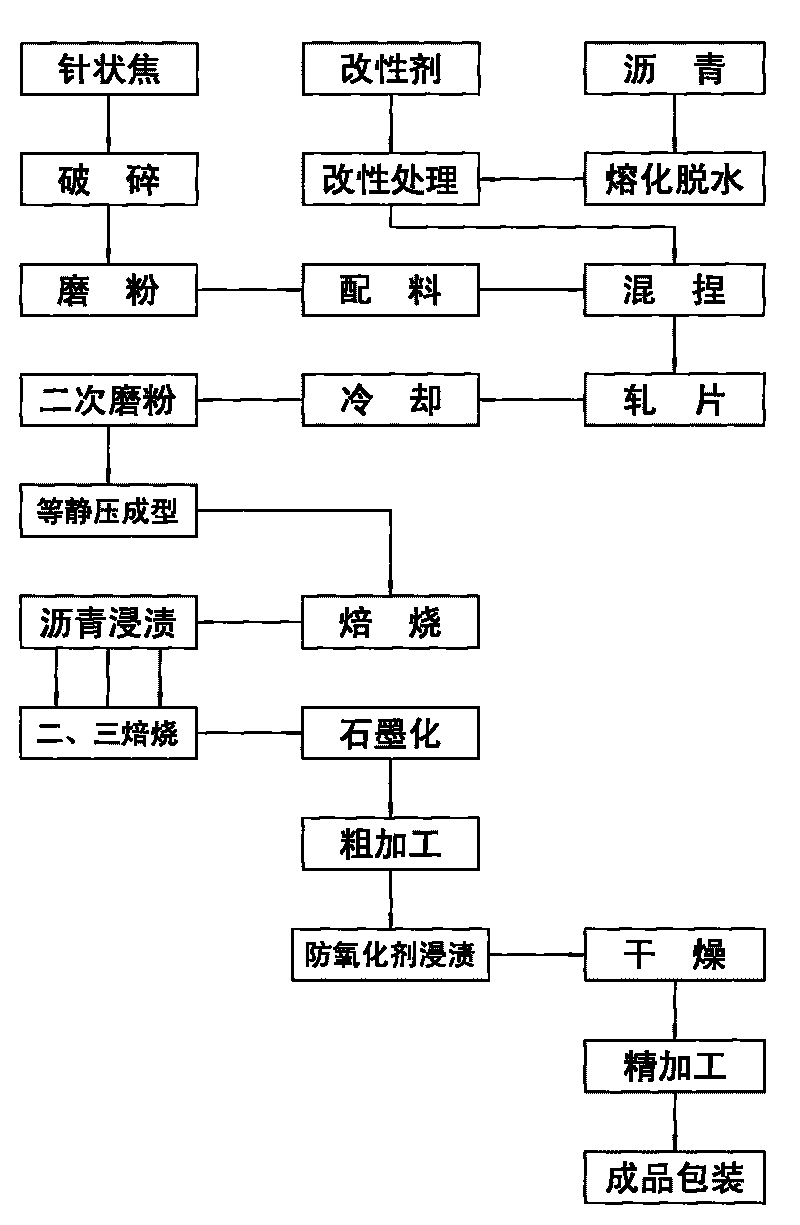

[0024] a. Select petroleum-based needle coke imported from Japan, crush and grind it into 300-400 mesh powder, and mix it with purchased titanium nitride and molybdenum disilicide with a particle size of 300-400 mesh. The weight of needle coke The percentage is 99.5-99.8%, the weight percentage of titanium nitride is 0.3-0.5%, and the weight percentage of molybdenum disilicide is 0.2-0.3%;

[0025] b. The high-temperature coal tar pitch is melted and dehydrated and modified by adding a phenolic resin. The weight ratio of the high-temperature coal tar pitch raw material to the phenolic resin before dehydration is 100: 3 to 5;

[0026] c. Mixing and kneading the powder ingredients obtained in step a and the modified asphalt obtained in step b respectively by weight percentage of 65-70% and 30-35%;

[0027] d. Use a flaking machine to flake the kneaded material, and after cooling, grind it into 100-150 mesh powder and then isostatically press it. Pressurize for 20-30 minutes, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com