Fibre reinforced vinyl ester resin base pultrusion composite

A vinyl ester resin and composite material technology, which is applied in the field of fiber-reinforced vinyl ester resin composite materials, can solve the problems of difficult to meet heat resistance, complex production process, reduced toughness of composite materials, etc., and achieve excellent high temperature resistance performance and mechanical properties. performance, excellent mechanical properties, and the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The composition of high temperature resistant vinyl ester resin composition is as follows:

[0024] Phenolic vinyl ester resin (Fuchem-890) 50 parts

[0025] Bisphenol A vinyl ester resin (Ashland H-922) 50 parts

[0026] Organic peroxide curing agent 2 parts

[0027] Of which: bis(4-tert-butylcyclohexyl) peroxydicarbonate

[0028] (trade name Perkadox-16): 0.5 parts

[0029] Tert-butyl peroxybenzoate (trade name Trigonox-C): 1.5 parts

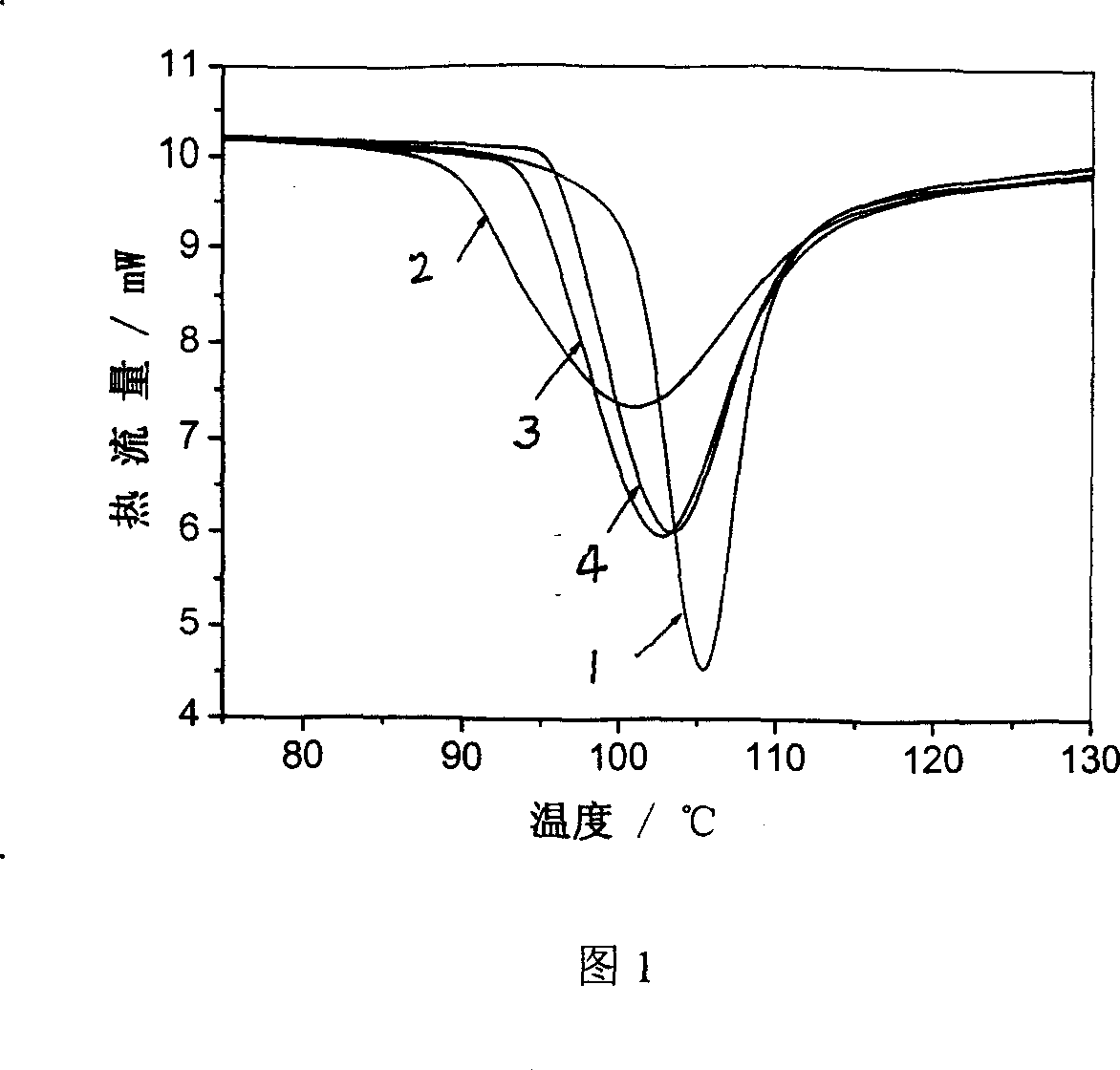

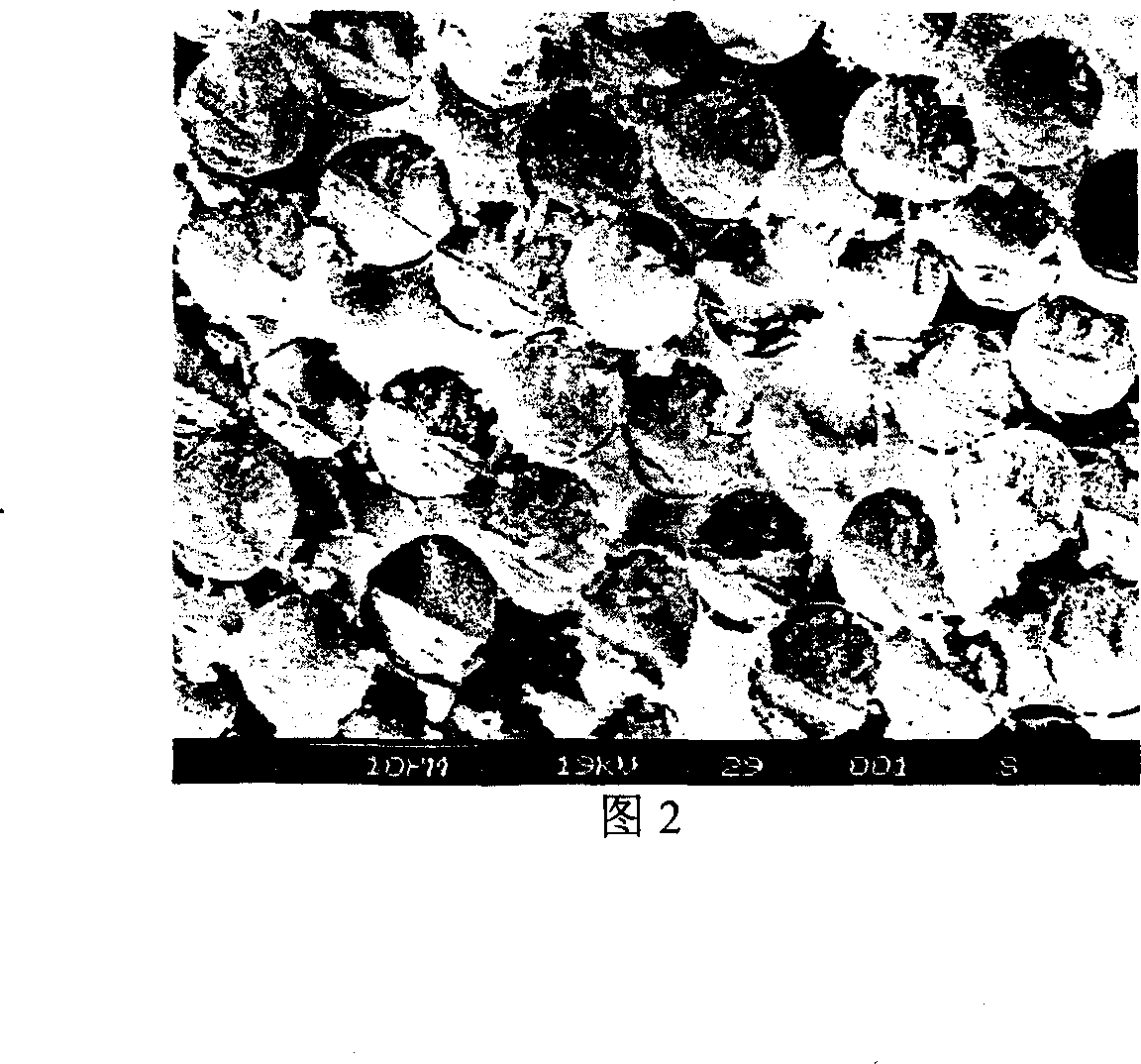

[0030] Release agent (trade name INT-PS125) 3 parts

[0031] After the above components are mixed and stirred evenly, pour into the dipping tank of the pultrusion equipment. The fiber reinforced material is T300-12K carbon fiber, and a carbon fiber reinforced resin-based unidirectional composite material is obtained, with a section width of 6mm and a thickness of 2mm, wherein the volume content of carbon fiber is 65%. The pultrusion process is stable, the interlayer shear strength of the product is 76MPa, the glass transition temp...

Embodiment 2

[0033] The composition of high temperature resistant vinyl ester resin composition is as follows:

[0034] 75 parts of phenolic vinyl ester resin

[0035] Bisphenol A type vinyl ester resin 25 parts

[0036] Organic peroxide curing agent 1.2 parts

[0037] Among them, bis(4-tert-butylcyclohexyl ester) peroxydicarbonate

[0038] (trade name Perkadox-16): 0.3 parts

[0039] Tert-butyl peroxybenzoate (trade name Trigonox-C): 0.9 parts

[0040] Release agent INT-PS125 1 part

[0041] nano-SiO 2 Filling 1 part

[0042] After the above components are mixed and stirred evenly, pour into the dipping tank of the pultrusion equipment. The fiber reinforced material is T300-12K carbon fiber and glass fiber cloth wrapped in the outer layer of carbon fiber, and the product is a flat strip-shaped continuous sucker rod with a cross-section of 32mm×4.2mm, and the volume content of the fiber is 60%. The pultrusion process is stable, the interlaminar shear strength of the product is 78MP...

Embodiment 3

[0044] The composition of high temperature resistant vinyl ester resin composition is as follows:

[0045] 95 parts of phenolic vinyl ester resin

[0046] Bisphenol A type vinyl ester resin 5 parts

[0047] Organic peroxide curing agent 0.8 parts

[0048] Of which Perkadox-16: 0.2 parts

[0049] Trigonox-C: 0.6 parts

[0050] Release agent INT-PS125 2 parts

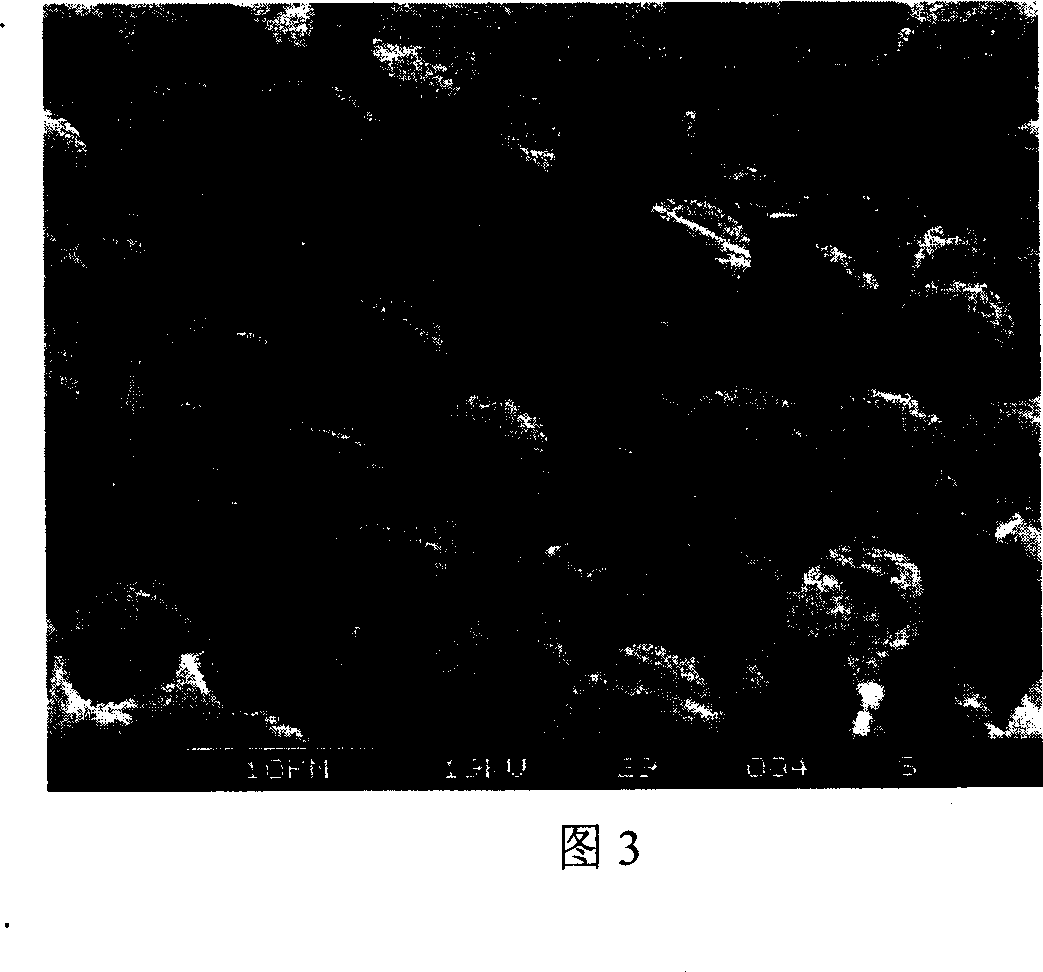

[0051] 300 mesh calcium carbonate filler 1 part

[0052] 2 parts of 300 mesh aluminum hydroxide filler

[0053] Active diluent MMA 2 parts

[0054] Inhibitor hydroquinone 0.005 parts

[0055] After the above components are mixed and stirred evenly, pour into the dipping tank of the pultrusion equipment. The fiber reinforced material is T300-12K carbon fiber and aramid fiber cloth coated on the outer layer of carbon fiber, and the product is a flat rod with a section of 32mm×4.2mm, and the volume content of the fiber is 55%. The pultrusion process is stable, the interlayer shear strength of the product is 79MPa, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com