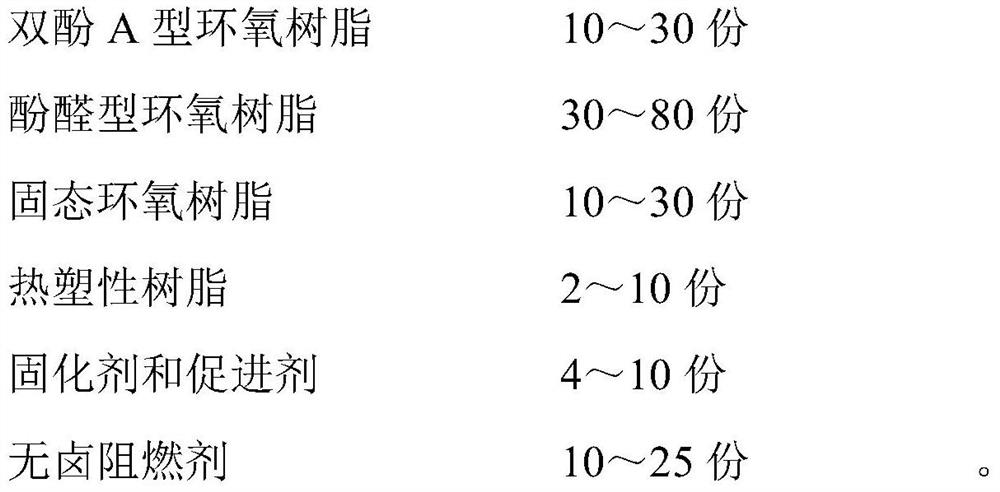

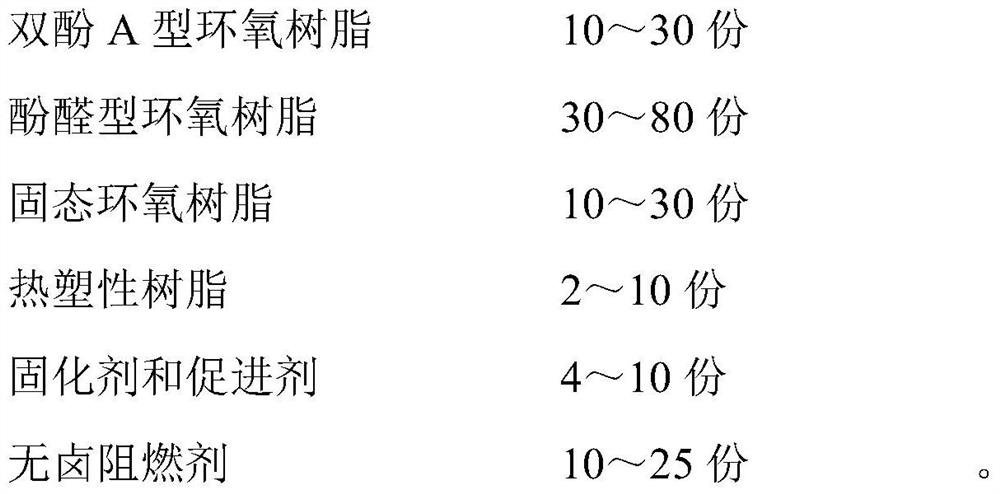

Halogen-free flame-retardant epoxy resin system for prepregs, and preparation method thereof

An epoxy resin system and epoxy resin technology, applied in the field of polymer materials, can solve the problems of destroying electrical properties, heat resistance and reliability of use, flame retardants cannot participate in the curing reaction of resin systems, and limited application range. Achieve uniform stability, high toughness, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Weigh 10 parts of bisphenol A liquid epoxy resin 128 and 4 parts of phenoxy resin in a reactor, heat up to 150°C under the protection of nitrogen, keep stirring for 4 hours, until the mixed liquid becomes clear, discharge, and cool to room temperature to obtain component a; then weigh 8 parts of bisphenol A liquid epoxy resin 128 and preheat to 50-70°C, add 2 parts of dicyandiamide curing agent EQ-14 and 2 parts of urea derivative accelerator UR-D, disperse evenly with a high-speed disperser, and then grind it in a three-roll mill for 3 to 6 times to obtain component b; then mix 75 parts of phenolic epoxy resin 638S, 10 parts of phosphorus nitrogen flame retardant FR- Add 01 to the double planetary mixer in turn, raise the temperature to 150°C, and stir at a revolution speed of 20-40 rpm and a dispersion speed of 750-1500 rpm for 1-3 hours to obtain component c; Add 1 part of component a and 16 parts of solid bisphenol A resin 901 to component c, stir in the container a...

Embodiment 2

[0062] Weigh 12 parts of bisphenol A liquid epoxy resin 128 and 2 parts of phenoxy resin in a reactor, heat up to 150°C under the protection of nitrogen, keep stirring for 4 hours, until the mixed liquid becomes clear, discharge, and cool to room temperature to obtain component a; then weigh 12 parts of bisphenol A liquid epoxy resin 128 and preheat to 50-70°C, add 4 parts of dicyandiamide curing agent 100S and 4 parts of urea derivative accelerator UR- 2T, disperse evenly with a high-speed disperser, and then grind it in a three-roller mill for 3 to 6 times to obtain component b; then mix 50 parts of phenolic epoxy resin 638S and 19 parts of phosphorus nitrogen flame retardant FR-01 in sequence Add it into a double planetary mixer, raise the temperature to 150°C, and stir at a revolution speed of 20-40 rpm and a dispersion speed of 750-1500 rpm for 1-3 hours to obtain component c; Add 1 part of component a and 10 parts of solid bisphenol A resin 902, stir in the container at ...

Embodiment 3

[0065] Weigh 15 parts of bisphenol A liquid epoxy resin 128 and 5 parts of polyvinyl alcohol phenolic resin in a reactor, heat up to 150°C under nitrogen protection, keep stirring for 4 hours, until the mixed liquid becomes clear and discharge , cooled to room temperature to obtain component a; then weigh 15 parts of bisphenol A liquid epoxy resin 128 and preheat it to 50-70°C, add 4 parts of dicyandiamide curing agent 1400F and 2 parts of urea derivative accelerator UR-41, disperse evenly with a high-speed disperser, and then grind it in a three-roll mill for 3 to 6 times to obtain component b; then mix 34 parts of phenolic epoxy resin 638S, 15 parts of phosphorus nitrogen flame retardant FR- 02 Add it to the double planetary mixer in sequence, raise the temperature to 150°C, and stir at a revolution speed of 20-40 rpm and a dispersion speed of 750-1500 rpm for 1-3 hours to obtain component c; Add 1 part of component a and 30 parts of solid bisphenol A resin 902 to component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com