Modified PGA material and preparation method thereof, and modified PGA film

A modification and raw material technology, applied in the field of modified PGA materials and their preparation, and modified PGA films, can solve the problems affecting practical use, poor mechanical properties and processability, etc., and achieve good thermodynamic compatibility, good Compatibility and interaction, effects of rheological enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

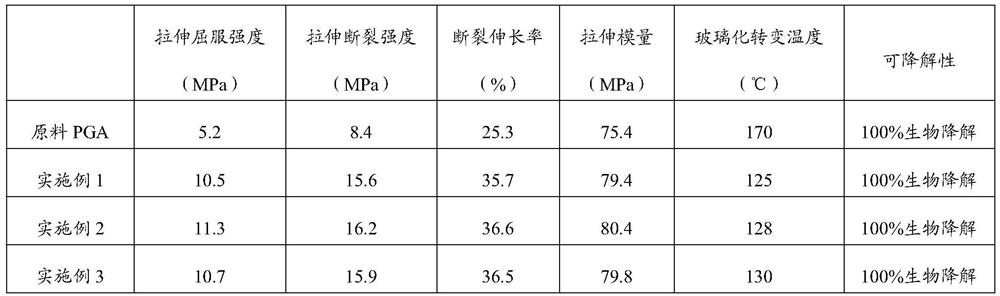

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the modified PGA material described in the above technical solution, comprising: mixing PGA, ionic liquid and filler, putting them into a twin-screw extruder to granulate, and then drying to obtain the modified PGA material. PGA material.

[0037] Wherein, the types and dosages of the PGA, ionic liquid and filler are consistent with those described in the previous technical solution, and will not be repeated here.

[0038] In the present invention, the mixing is performed by using a high-speed machine. The rotational speed of the mixing is preferably 90-100 rpm; the mixing time is preferably 1-1.5 h.

[0039] After the above mixing, the resulting mixture is put into a twin-screw extruder for granulation. Among the present invention, the condition of described twin-screw extruder is as follows:

[0040] Length-to-diameter ratio ≥ 1:55;

[0041] The temperature of the feeding section is 130-160°C, preferably 1...

Embodiment 1

[0053] 1. Raw materials:

[0054] 80 parts of PGA (weight average molecular weight is 100,000, melting point is 220°C);

[0055] 15 parts of 1-pentyl-3-methylimidazolium tetrafluoroborate;

[0056] Filler (talcum powder) 5 parts.

[0057] 2. Preparation:

[0058] Put PGA, ionic liquid and filler into a high-speed mixer, and mix at 90 rpm for 1 hour to obtain a mixture. The resulting mixture was put into a twin-screw extruder for granulation. The aspect ratio of the twin-screw extruder was 1:55, the temperature of the feeding section was kept at 150°C, the temperature of the mixing section was 230°C, and the temperature of the extrusion section was 230°C. And maintain vacuum treatment in the extrusion section. The material is granulated by means of water-stretching, and the temperature of the water tank is 55°C. The resulting masterbatch was dried at 80° C. for 2 hours to obtain a modified PGA material. The resulting product is packaged in aluminum foil, vacuumized and st...

Embodiment 2

[0060] 1. Raw materials:

[0061] 70 parts of PGA (weight average molecular weight is 200,000, melting point is 225°C);

[0062] 15 parts of 1-pentyl-3-methylimidazolium tetrafluoroborate;

[0063] Filler (nanometer calcium carbonate) 15 parts.

[0064] 2. Preparation:

[0065] PGA, ionic liquid and filler were put into a high-speed mixer, and mixed for 2 hours at 100 rpm to obtain a mixture. The resulting mixture was put into a twin-screw extruder for granulation. The aspect ratio of the twin-screw extruder was 1:45, the temperature of the feeding section was kept at 150°C, the temperature of the mixing section was 230°C, and the temperature of the extrusion section was 230°C. And maintain vacuum treatment in the extrusion section. The material is granulated by means of water-stretching, and the temperature of the water tank is 60°C. The resulting masterbatch was dried at 80° C. for 2 hours to obtain a modified PGA material. The resulting product is packaged in aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com