A kind of hydrophobic and heat-resistant thermoplastic elastomer and its preparation method

A technology of thermoplastic elastomers and elastomers, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., to achieve the effects of preventing ice hanging, improving thermodynamic compatibility, improving hydrophobicity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

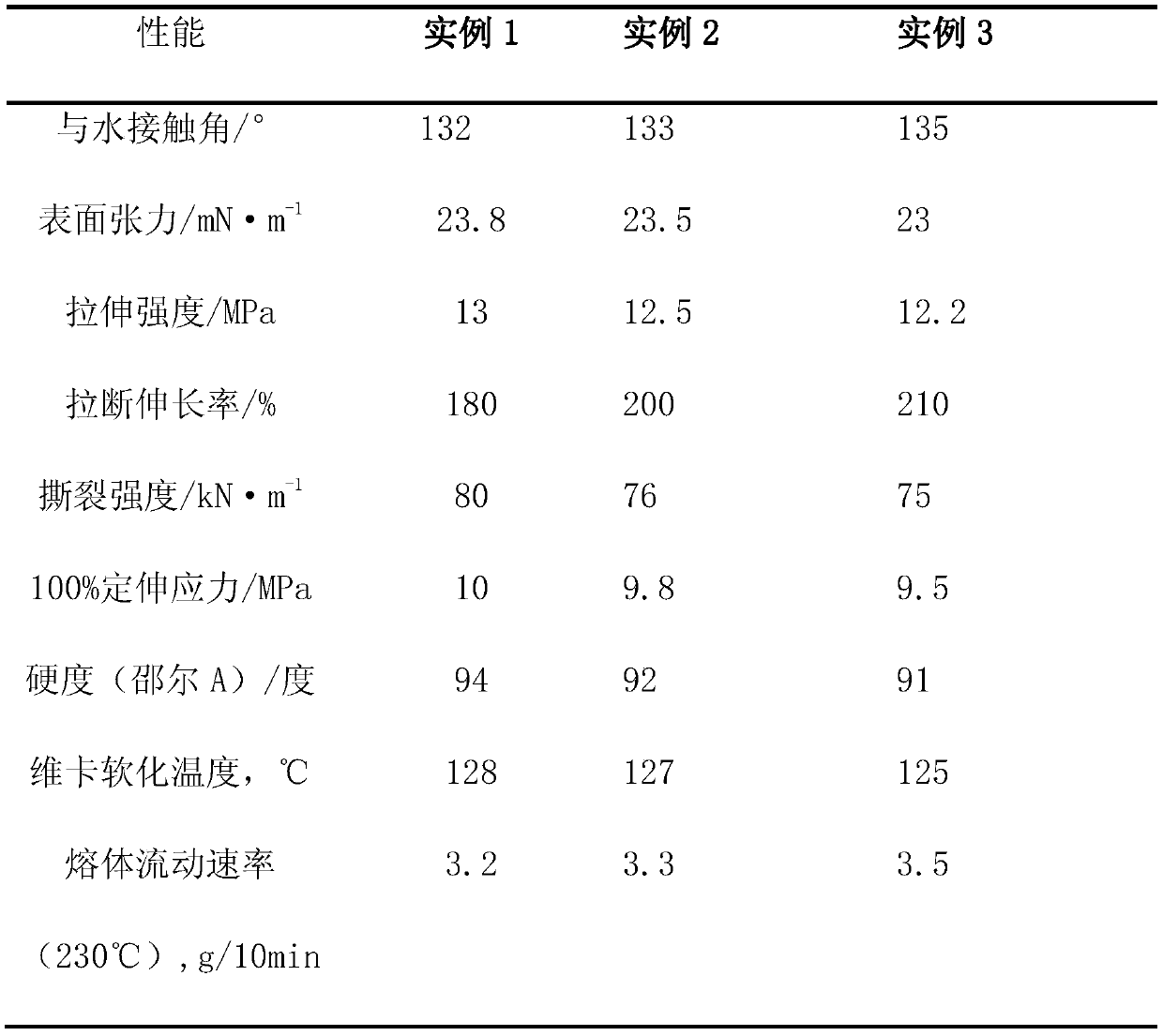

Examples

Embodiment approach 1

[0034] (1) First mix MVQ with white carbon black, silane coupling agent, and peroxide vulcanizing agent on an open mill to make MVQ masterbatch, and prepare the next sheet for later use; the ratio is 100:20:1:1.

[0035] (2) Mix POE with the above-mentioned MVQ masterbatch and polytetrafluoroethylene micropowder on a high-temperature open mill, and then cut into strips for subsequent use; the blending ratio is 100:110:6, and the temperature of the high-temperature open mill is 90°C.

[0036] (3) Extrude the above rubber strip with a twin-screw extruder, and dynamically vulcanize it to make PMTPV; the temperature of the feeding section of the extruder is 135°C, the temperature of the plasticizing section is 140°C, the temperature of the extrusion section is 145°C, and the temperature of the head is 140°C , the screw speed is 80rpm.

[0037] (4) After mixing the PP and PMTPV pellets evenly, the ratio is: 100:135; use a twin-screw extruder to extrude and granulate, the temperatu...

Embodiment approach 2

[0039] (1) Mix MVQ with white carbon black, silane coupling agent, and peroxide vulcanizing agent on an open mill, and then prepare the next sheet for later use; the ratio is 100:25:1:1.

[0040] (2) Mix POE and the above-mentioned MVQ masterbatch in an internal mixer evenly, put the sheets on and off the open mixer, cut into rubber strips, and granulate for later use; the blending ratio is 100:120.

[0041] (3) Extrude and granulate the above-mentioned pellets with a twin-screw extruder, and dynamically vulcanize them to make PMTPV; 140°C, the screw speed is 80rpm.

[0042] (4) After mixing PP, PMTPV pellets and polytetrafluoroethylene micropowder evenly, the ratio is: 100:140:5; use a twin-screw extruder to extrude and granulate to obtain the material of the present invention. The temperature of the feeding section of the extruder is 180°C, the temperature of the plasticizing section is 185°C, the temperature of the extrusion section is 190°C, the temperature of the head is 1...

Embodiment approach 3

[0044] (1) First mix MVQ with white carbon black, silane coupling agent, and peroxide vulcanizing agent on an open mill to make MVQ masterbatch, and prepare the next sheet for later use; the ratio is 100:25:1:1.

[0045] (2) Mix POE with the above-mentioned MVQ masterbatch and polytetrafluoroethylene micropowder on a high-temperature open mill, and then cut into strips for later use; the blending ratio is 100:130:6, and the temperature of the high-temperature open mill is 90°C.

[0046] (3) Extrude the above rubber strip with a twin-screw extruder, and dynamically vulcanize it to make PMTPV; the temperature of the feeding section of the extruder is 135°C, the temperature of the plasticizing section is 140°C, the temperature of the extrusion section is 145°C, and the temperature of the head is 140°C , the screw speed is 80rpm.

[0047] (4) After mixing the PP and PMTPV pellets evenly, the ratio is: 100:145; use a twin-screw extruder to extrude and granulate, the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com