Low-temperature-resistant low-hardness thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, low hardness technology, used in the field of polymer elastomers, can solve the problems of oil precipitation, large permanent deformation of products, poor dispersibility, etc., to improve the interface condition, good low temperature resistance and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

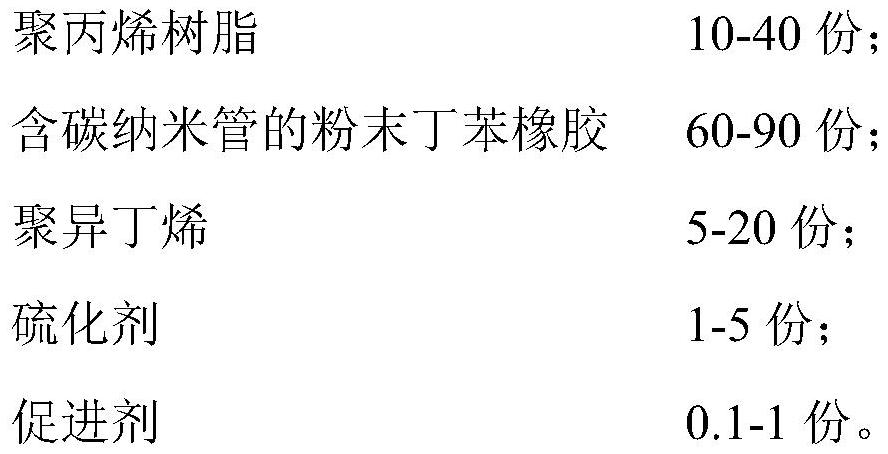

Method used

Image

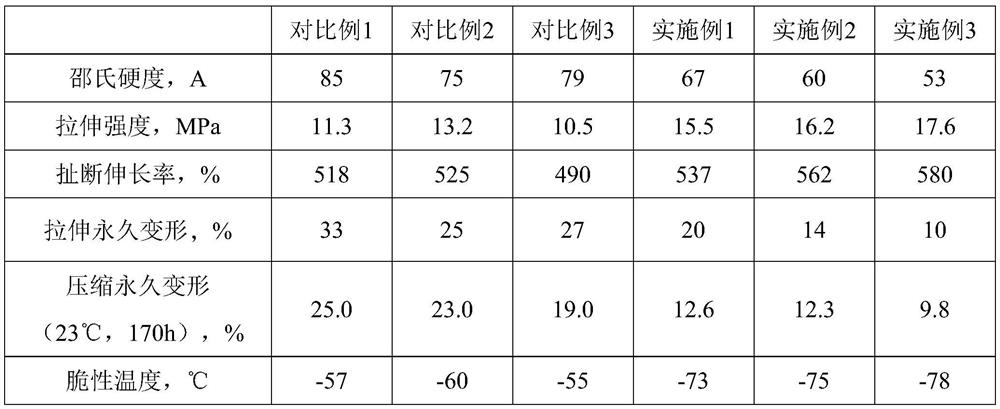

Examples

Embodiment 1

[0038] Weigh 80 parts of powdered styrene-butadiene rubber containing carbon nanotubes, 20 parts of PP230G, 5 parts of PIB1300, 5 parts of vulcanizing agent BPDH, and 1 part of accelerator TAIC, and premix them in an internal mixer for 5 minutes to make a premix, and then Put the premixed material into the twin-screw extruder for reaction extrusion, granulation, the temperature is controlled at 160-165°C, the screw rotation frequency is 5Hz, and then the pellets are pressed on the Brabender single-screw extruder at 170-185°C A 2mm thick TPV sheet is produced, and a dumbbell-shaped sample is cut out by a sample making machine.

Embodiment 2

[0040] Weigh 75 parts of powdered styrene-butadiene rubber containing carbon nanotubes, 25 parts of PP230G, 20 parts of PIB1300, 1 part of vulcanizing agent BPDH, and 0.1 part of accelerator TAIC, and premix them in an internal mixer for 5 minutes to make a premix, and then Put the premixed material into the twin-screw extruder for reaction extrusion, granulation, the temperature is controlled at 160-165°C, the screw rotation frequency is 5Hz, and then the pellets are pressed on the Brabender single-screw extruder at 170-185°C A 2mm thick TPV sheet is produced, and a dumbbell-shaped sample is cut out by a sample making machine.

Embodiment 3

[0042] Weigh 68 parts of powdered styrene-butadiene rubber containing carbon nanotubes, 32 parts of PP230G, 10 parts of PIB1300, 3 parts of vulcanizing agent BPDH, and 0.5 parts of accelerator TAIC and pre-mix them in an internal mixer for 5 minutes to make a premix, and then Put the premixed material into the twin-screw extruder for reaction extrusion, granulation, the temperature is controlled at 160-165°C, the screw rotation frequency is 5Hz, and then the pellets are pressed on the Brabender single-screw extruder at 170-185°C A 2mm thick TPV sheet is produced, and a dumbbell-shaped sample is cut out by a sample making machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com