A polyoxymethylene nanoporous film with micro-nano double continuous porous structure and preparation method thereof

A technology of nanoporous film and porous structure, which is applied in the field of polyoxymethylene nanoporous film with micro-nano double continuous porous structure and its preparation, which can solve the problem of poor uniformity of microporous film pore structure, difficulty in mixing uniformly, and high requirements for production equipment. problem, to achieve the effect of high porosity, good mechanical strength and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

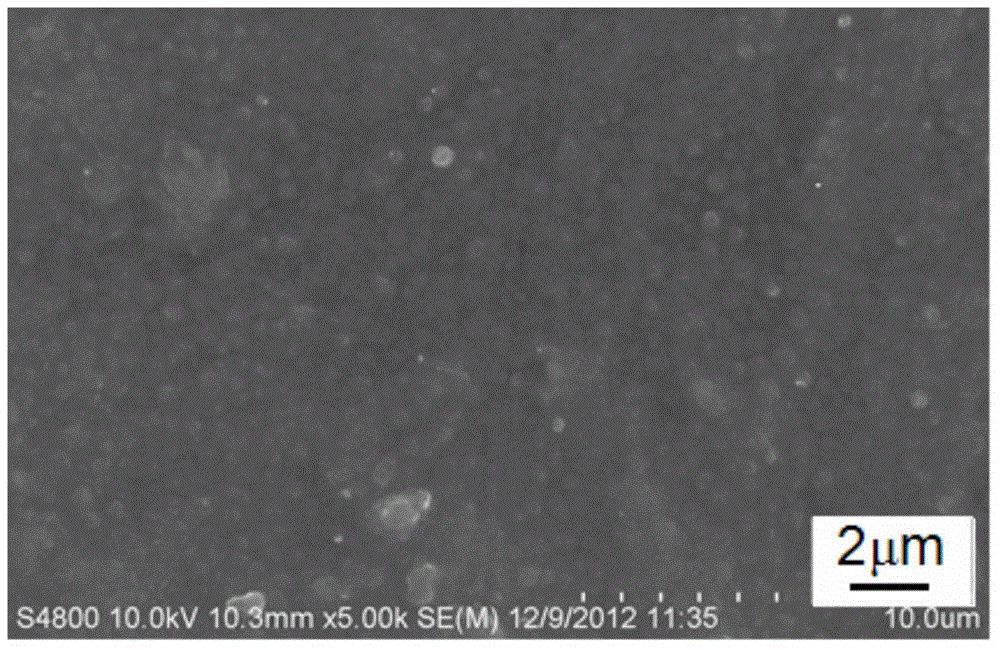

[0045] Dry polylactic acid and polyoxymethylene in a vacuum drying oven at 80°C overnight, and then add 10g polylactic acid and 90g polyoxymethylene to the internal mixer. The temperature of the internal mixer is 190°C and the rotor speed is 20rpm / min. Mix for 1 min; then increase the rotor speed to 50 rpm / min and mix for 5 min before discharging, and cool to normal temperature. Then, the above-mentioned melt-kneaded mixture was hot pressed into a film with a thickness of 10 μm in a hot press at 190° C., and then quenched after hot pressing for 1 min. Then the film was immersed in a 1mol / L NaOH solution, kept at a constant temperature of 65°C for 120h, after hydrolysis to remove polylactic acid, washed with distilled water, and finally a polyoxymethylene nanoporous film was obtained.

Embodiment 2

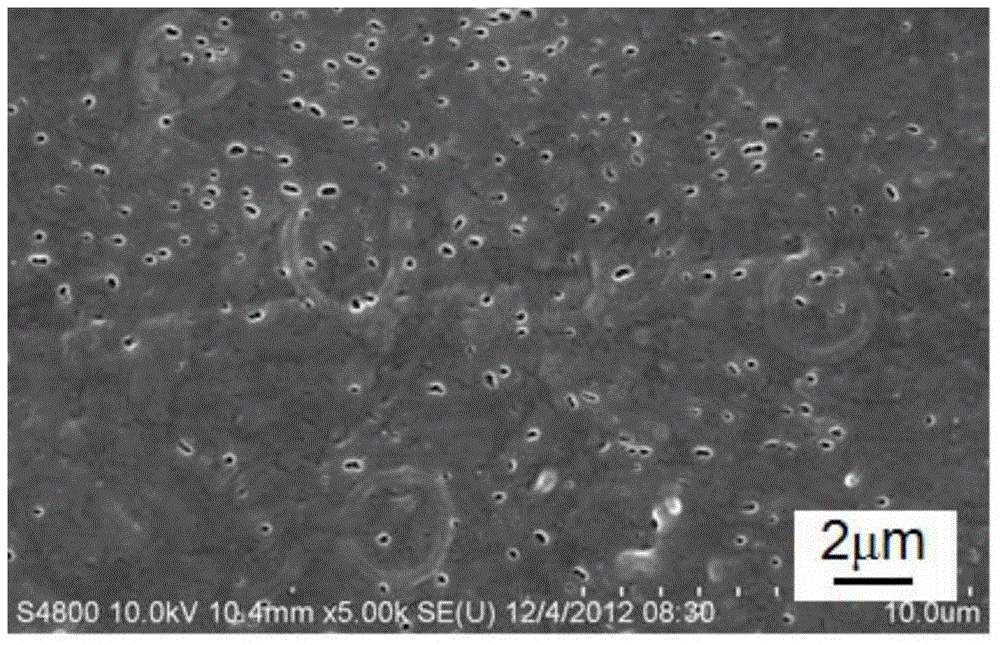

[0047] The weight of the raw material polylactic acid in Example 1 was changed to 50 g, and the weight of POM was changed to 50 g, and the other experimental conditions were the same as in Example 1. Finally, the polyoxymethylene nanoporous film was obtained.

Embodiment 3

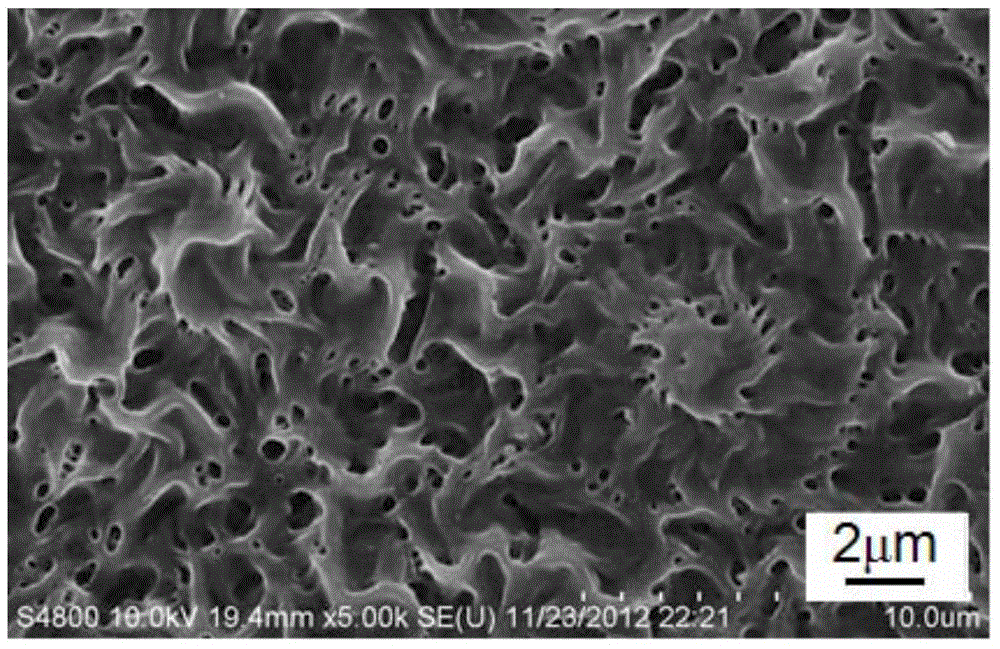

[0049] The weight of the raw material polylactic acid in Example 1 was changed to 60 g, and the weight of POM was changed to 40 g. The other experimental conditions were the same as those in Example 1. Finally, the polyoxymethylene nanoporous film was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com