Aromatic polyamide-contained ternary alloy and preparation method thereof

A technology of aromatic polyamide and naphthalene aromatic polyamide, which is applied to the field of ternary alloy containing aromatic polyamide and its preparation, and can solve the problems of limiting the application scope of aromatic polyamide, difficulty in processing, exceeding and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

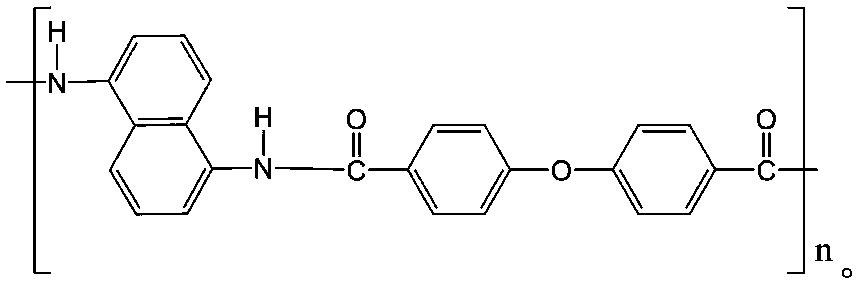

[0039] In the present invention, the aromatic polyamide is a method for preparing aromatic polyamide containing naphthalene, preferably comprising the following steps: 1,5-naphthalene diamine and 4,4'-diphenyl ether diacid chloride are 1 in a molar ratio: Mixed in a ratio of 1, using NMP as a solvent and LiCl as a catalyst to undergo a polymerization reaction at room temperature; the present invention does not have any special restrictions on the amount of NMP and LiCl, and the amount known to those skilled in the art can be used. In the present invention, the structural formula of the naphthalene-containing aromatic polyamide is preferably:

[0040]

[0041] In the present invention, there is no special limitation on n in the structural formula, and the reduced viscosity of the aromatic polyamide containing naphthalene can be in the range of 0.4 to 1.0 dL / g, and the glass transition temperature can be in the range of 285 to 288°C. Can.

[0042] The present invention also ...

Embodiment 1

[0061] Mix 6g of PK-1 powder, 6g of PEI powder, 1g of LiCl and 60mL of NMP, dissolve it under stirring conditions and discharge it into deionized water. After pulverizing the crude product, wash it three times with boiled deionized water and absolute ethanol respectively. Dry to obtain powdered PK-1 / PEI binary blend;

[0062] After mixing 94g of PEEK powder and 6g of PK-1 / PEI binary blend powder, add it to a high-speed mixer, stir at a high speed for 10 minutes, mix well, put it in a vacuum oven at 100°C for 8 hours, and add the dried mixture Into a twin-screw extruder, extrude at a temperature of 370°C and a screw speed of 40r / min, granulate, and dry in vacuum at 120°C for 12 hours to obtain PEEK / PEI / PK-1 ternary alloy pellets material;

[0063] PEEK / PEI / PK-1 ternary alloy pellets were injection molded under the conditions of 380°C and 750bar, and then annealed at 210°C for 4 hours to obtain PEEK / PEI / PK-1 ternary alloy.

Embodiment 2

[0065] Mix 10g of PK-1 powder, 10g of PEI powder, 2g of LiCl and 150mL of NMP, dissolve under stirring conditions and discharge in deionized water, grind the crude product and wash with boiled deionized water and absolute ethanol three times respectively, Dry to obtain powdered PK-1 / PEI binary blend;

[0066] After mixing 90g of PEEK powder and 10g of PK-1 / PEI binary blend powder, add it to a high-speed mixer, stir at a high speed for 10 minutes, mix well, put it in a vacuum oven at 100°C for 8 hours, and add the dried mixture Into a twin-screw extruder, extrude at a temperature of 380°C and a screw speed of 40r / min, granulate, and dry in vacuum at 120°C for 12 hours to obtain PEEK / PEI / PK-1 ternary alloy pellets material;

[0067] PEEK / PEI / PK-1 ternary alloy pellets were injection molded under the conditions of 400°C and 900bar, and then annealed at 200°C for 5 hours to obtain PEEK / PEI / PK-1 ternary alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com