High toughness and high modulus polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of polypropylene, can solve the problems of poor toughness of polypropylene, and achieve the effects of reduced interfacial tension, good electrical insulation, and uniform distribution of copolymer sequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

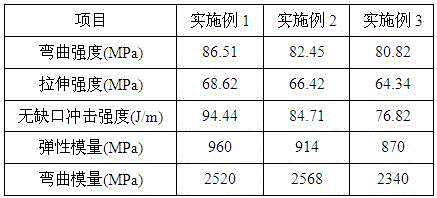

Examples

Embodiment 1

[0022] High toughness and high modulus polypropylene composite material, composed of 60 parts of polypropylene matrix, 10 parts of high density polyethylene, 13 parts of polyolefin elastomer, 7 parts of modified wollastonite, 1 part of nano-modified titanium dioxide, and 1 part of modified Boron nitride, 5 parts of maleic anhydride grafted polypropylene, 1 part of anti-phosphite antioxidant and 2 parts of dimethyl silicone oil, wherein the nano-modified particles are silane-coupled with a weight ratio of 1:100 It is made by mixing titanium dioxide with a particle size of 10nm; modified wollastonite is made by mixing silane coupling agent with a weight ratio of 1.5:100 and wollastonite with a particle size of 1250 mesh; modified boron nitride is made by a weight ratio of It is made by mixing 2:100 silane coupling agent and monolayer boron nitride with an average particle size of 5 microns.

[0023] The preparation method of high-toughness and high-modulus polypropylene composit...

Embodiment 2

[0025]High toughness and high modulus polypropylene composite material, composed of 50 parts of polypropylene matrix, 12 parts of high density polyethylene, 15 parts of polyolefin elastomer, 9 parts of modified wollastonite, 2 parts of nano-modified titanium dioxide, 2 parts of modified Boron nitride, 6 parts of maleic anhydride grafted polypropylene, 1.5 parts of anti-phosphite antioxidant and 2.5 parts of dimethyl silicone oil, wherein the nano-modified particles are silane-coupled with a weight ratio of 1:100 It is made by mixing titanium dioxide with a particle size of 10nm; modified wollastonite is made by mixing silane coupling agent with a weight ratio of 1.5:100 and wollastonite with a particle size of 1250 mesh; modified boron nitride is made by a weight ratio of It is made by mixing 2:100 silane coupling agent and monolayer boron nitride with an average particle size of 5 microns.

[0026] The high-toughness and high-modulus polypropylene composite material is prepar...

Embodiment 3

[0028] High toughness and high modulus polypropylene composite material, composed of 57 parts of polypropylene matrix, 11 parts of high density polyethylene, 13 parts of polyolefin elastomer, 7.5 parts of modified wollastonite, 1.5 parts of nano-modified titanium dioxide, 1.5 parts of modified Boron nitride, 5.5 parts of maleic anhydride grafted polypropylene, 1 part of anti-phosphite antioxidant and 2 parts of dimethyl silicone oil, wherein the nano-modified particles are silane-coupled with a weight ratio of 1:100 It is made by mixing titanium dioxide with a particle size of 10nm; modified wollastonite is made by mixing silane coupling agent with a weight ratio of 1.5:100 and wollastonite with a particle size of 1250 mesh; modified boron nitride is made by a weight ratio of It is made by mixing 2:100 silane coupling agent and monolayer boron nitride with an average particle size of 5 microns.

[0029] The high-toughness and high-modulus polypropylene composite material is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com