Fiber-enhanced polypropylene material and preparation method thereof

A polypropylene material and fiber-reinforced technology, which is applied in the field of modification of polymer composite materials, can solve problems such as poor thermal conductivity, achieve the effects of improving thermal conductivity, excellent friction and wear performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

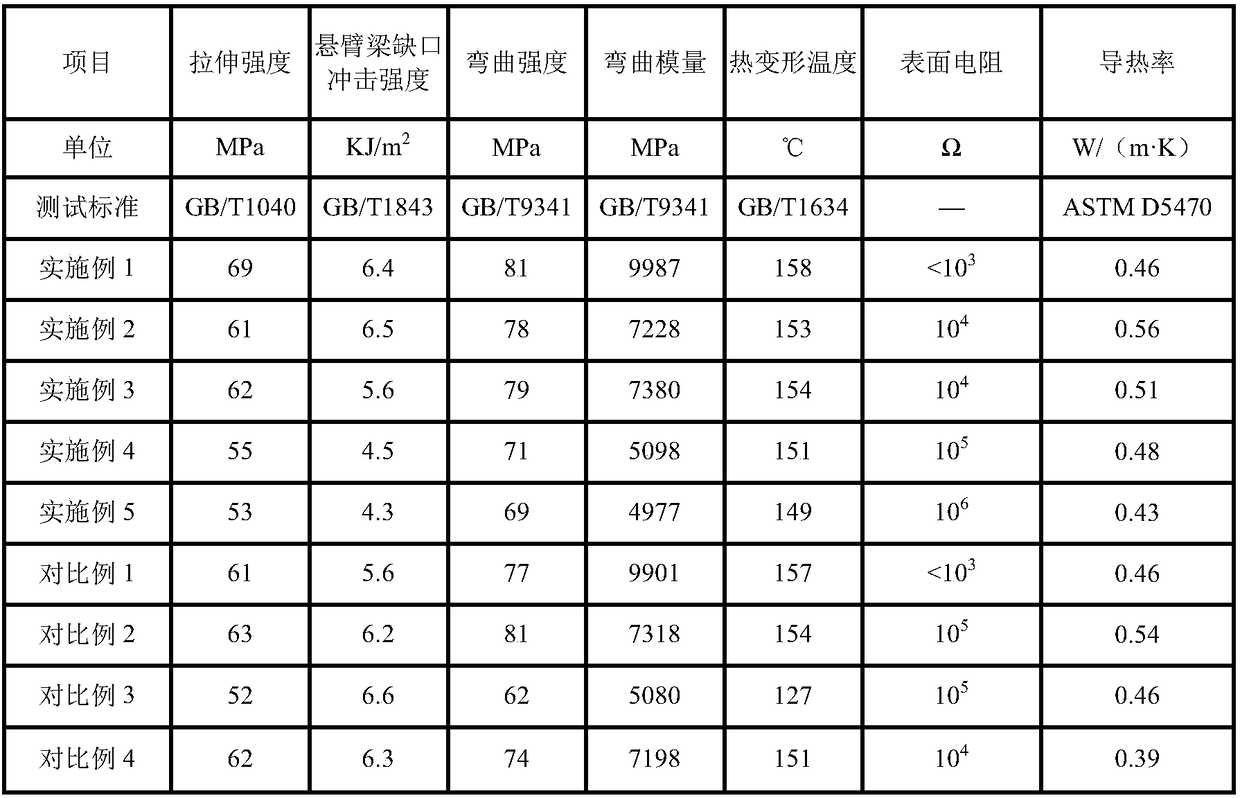

[0043] This embodiment provides a fiber-reinforced polypropylene material and a preparation method thereof.

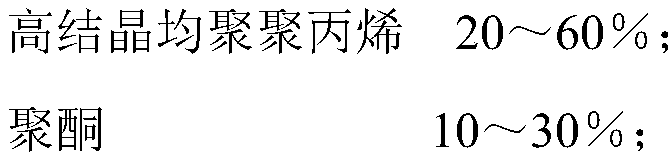

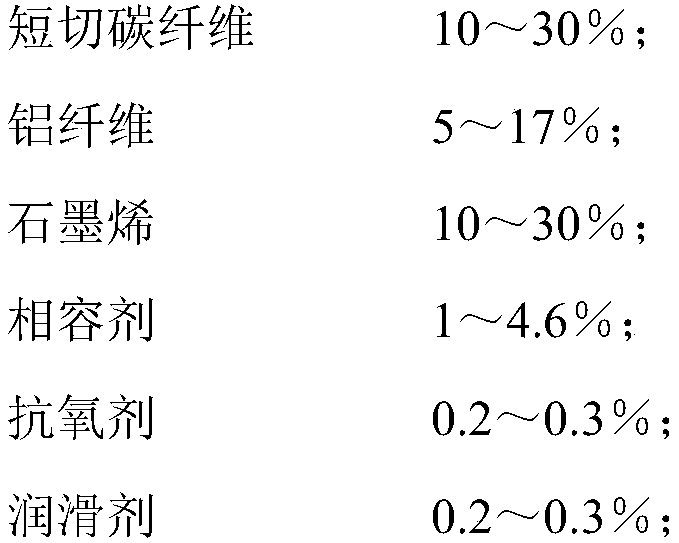

[0044] The fiber-reinforced polypropylene material is proportioned according to the following mass percentage composition:

[0045] High crystalline homopolypropylene 20% (brand: PPMM20-S, China Petrochemical Corporation Maoming Branch), polyketone 30% (brand: M230A, Korea Hyosung Corporation), chopped carbon fiber 30% (brand: PX35CA0250-65, Japan Toray Corporation), aluminum fiber 5% (dimension length 4mm, fiber diameter 90um, Xinyu Jintong Industrial Co., Ltd.), graphene 13.6% (brand: KNG-T181-2, Xiamen Kaina Graphene Technology Co., Ltd.), 1% of compatibilizer (brand: 1001, PP-g-MAH, Israel Pryron Co., Ltd.), 0.1% of antioxidant 1790 (model: 1790, American Cytec Chemical Co., Ltd.), anti-oxidant Oxygen 626 was 0.1% (model: SONOX 626, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) and lubricant 0.2% (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Lt...

Embodiment 2

[0050] This embodiment provides a fiber-reinforced polypropylene material and a preparation method thereof.

[0051] The fiber-reinforced polypropylene material is proportioned according to the following mass percentage composition:

[0052] 20% high crystalline homopolypropylene (brand: PPMM20-S, Maoming Branch of China Petrochemical Corporation), 20% polyketone (brand: M230A, South Korea Hyosung Corporation), 20% chopped carbon fiber (brand: PX35CA0250-65, Japan Toray Corporation), aluminum fiber 5% (dimension length 4mm, fiber diameter 90um, Xinyu Jintong Industrial Co., Ltd.), graphene 30% (brand: KNG-T181-2, Xiamen Kaina Graphene Technology Co., Ltd.), 4.6% of compatibilizer (brand: 1001, PP-g-MAH, Israel Pryron Co., Ltd.), 0.1% of antioxidant 1790 (model: 1790, American Cytec Chemical Co., Ltd.), anti-oxidant Oxygen 626 was 0.1% (model: SONOX 626, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) and lubricant 0.2% (calcium stearate 3818, Zhongshan Huamingtai Chemica...

Embodiment 3

[0057] This embodiment provides a fiber-reinforced polypropylene material and a preparation method thereof.

[0058] The fiber-reinforced polypropylene material is proportioned according to the following mass percentage composition:

[0059] High crystalline homopolypropylene 30% (brand: PPMM20-S, China Petrochemical Corporation Maoming Branch), polyketone 16.6% (brand: M230A, Korea Hyosung Corporation), chopped carbon fiber 20% (brand: CO70CP006-PEY, Korea Amos composites company), aluminum fiber 10% (dimension length 4mm, fiber diameter 90um, Xinyu Jintong Industrial Co., Ltd.), graphene 20% (brand: KNG-T181-2, Xiamen Kaina graphene Technology Co., Ltd.), 3% of compatibilizer (brand: 1001, PP-g-MAH, Israel Pryron Co., Ltd.), 0.1% of antioxidant 1790 (model: 1790, American Cytec Chemical Co., Ltd.), anti-oxidant Oxygen 626 was 0.1% (model: SONOX 626, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) and lubricant 0.2% (calcium stearate 3818, Zhongshan Huamingtai Chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Dimension length | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com