Photopolymer/liquid crystal/zinc sulfide nano-composite holographic grating and preparation method therefor

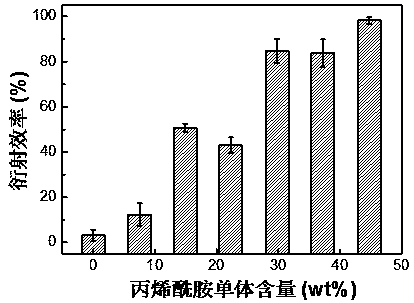

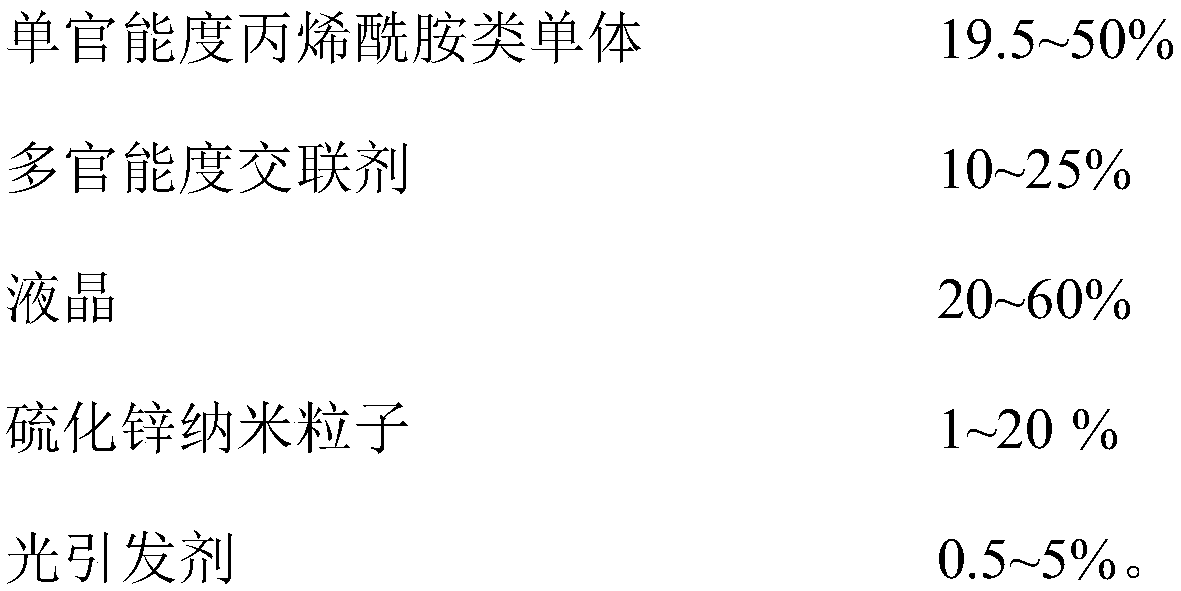

A photopolymer and nanocomposite technology, applied in the directions of diffraction gratings, optics, optical components, etc., can solve the problem of high driving voltage, and achieve the effect of improving low-frequency conductivity and improving diffraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

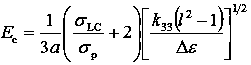

Method used

Image

Examples

Embodiment 1

[0034] A photopolymer / liquid crystal / ZnS holographic nanocomposite grating with a diffraction efficiency of 96% and a driving voltage of 2.5 V / μm, in which the photopolymer content is 39 wt%, the liquid crystal 8OCB content is 60 wt%, and the average particle size is 20 nm The ZnS nanoparticles content was 1 wt%.

[0035] Its preparation method is as follows:

[0036] Acrylamide (mass fraction 20 wt%), polyethylene glycol diacrylate (mass fraction 18.5 wt%), Irgacure184 (mass fraction 0.5 wt%), liquid crystal 8OCB (mass fraction 60 wt%) and zinc sulfide nanoparticles ( Average particle size 20 nanometers, mass fraction 1 wt%) were added respectively in the brown sample bottle, ultrasonic 30 minutes under 50 ℃, obtain uniform mixed solution;

[0037] will step The prepared mixed solution is poured into a liquid crystal cell made of glass with a conductive coating, and the thickness of the liquid crystal cell is 100 microns;

[0038] Divide a beam of 365nm laser light...

Embodiment 2

[0040] A photopolymer / liquid crystal / ZnS holographic nanocomposite grating with a diffraction efficiency of 94% and a driving voltage of 2.5 V / μm, in which the photopolymer content is 61.5 wt%, the liquid crystal 7CB content is 31.5 wt%, and the average particle size is 5 nm The ZnS nanoparticles content was 8 wt%.

[0041] Its preparation method is as follows:

[0042] N,N-dimethylacrylamide (mass fraction 40 wt%), hyperbranched acrylate 6361-100 (mass fraction 20 wt%), photoinitiator 3,3′-carbonyl bis(7-diethylamine aromatic Soybean) / N-phenylglycine (mass fraction 1.5 wt%), liquid crystal 7 CB (mass fraction 31.5 wt%) and zinc sulfide nanoparticles (average particle size 5 nm, mass fraction 8 wt%) were added to the brown sample bottle , ultrasonicated at 50 degrees Celsius for 30 minutes to obtain a homogeneous mixture;

[0043] will step The prepared mixed solution is poured into a liquid crystal cell made of glass with a conductive coating, and the thickness of t...

Embodiment 3

[0046] Photopolymer / LCD / ZnS holographic nanocomposite grating with a diffraction efficiency of 90% and a driving voltage of 2.2 V / μm, in which the photopolymer content is 60 wt%, the liquid crystal P01616A content is 20 wt%, and the average particle size is 100 nm The content of ZnS nanoparticles is 20wt%.

[0047] Its preparation method is as follows:

[0048] N-methylolacrylamide and methacrylamide (mass fractions were 20 wt% and 29 wt% respectively), pentaerythritol tetraacrylate (mass fraction 10 wt%), photoinitiator Rose Bengal / N-phenylglycine (mass fraction 1 wt%), liquid crystal P01616A (mass fraction 20 wt%), and zinc sulfide nanoparticles (average particle size 100 nm, mass fraction 20 wt%) were added to brown sample bottles, ultrasonic at 50 degrees Celsius for 30 minutes, Obtain a homogeneous mixture;

[0049] will step The prepared mixed solution is poured into a liquid crystal cell made of glass with a conductive coating, and the thickness of the liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com