Dyeing process for polyester fabric

A polyester and fabric technology, applied in the field of polyester fabric dyeing technology, can solve the problems of poor dyeing quality of polyester fiber, low dyeing rate of polyester fiber, lack of active groups, etc. The effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

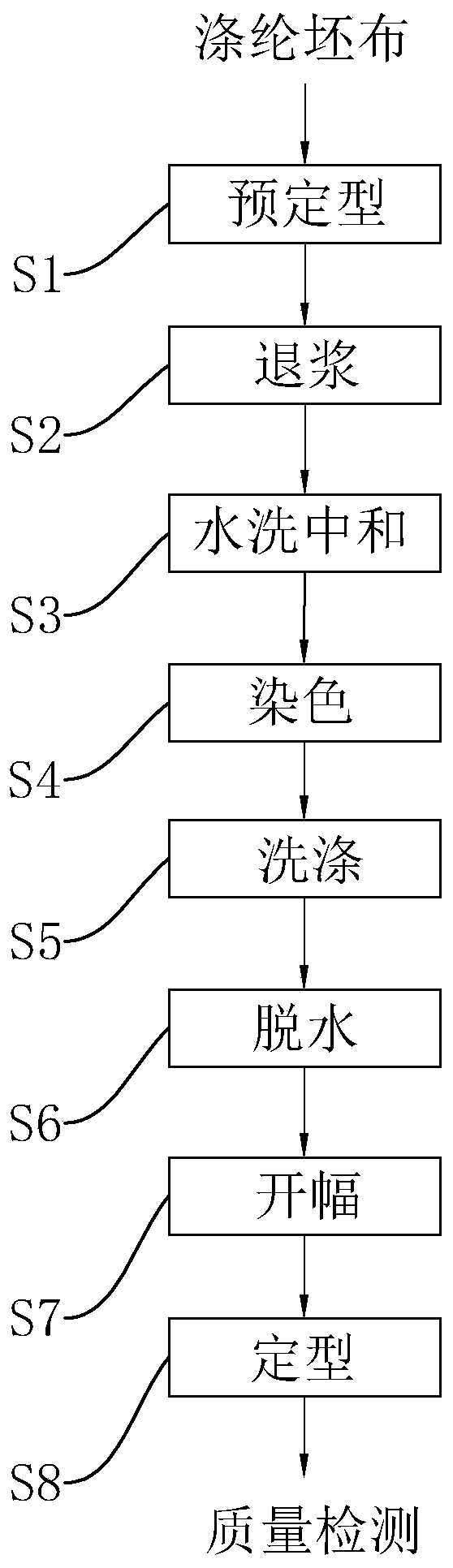

[0039] Reference figure 1 , A dyeing process for polyester fabrics, the polyester grey fabric after unwinding is processed in the following steps:

[0040] S1: Pre-defined. First transport the selected grey fabric into the heat setting machine, and then adjust the temperature of the heat setting machine to 160°C for 4.5 minutes, and then cool the polyester fabric to room temperature.

[0041] S2: Desizing. The pre-shaped grey fabric is put into the padding mill. Then, the desizing solution is added, and the chemical composition of the desizing solution is 40 g / L of caustic soda and 10 g / L of deoiling refining agent. When adding, first add caustic soda to the padding mill and stir for 10 minutes; then add the degreasing refining agent to the padding mill, control the bath ratio of 1:30, and stir for 30 minutes; then the grey fabric is paddled in the padding mill for 7 hours.

[0042] S3: Wash and neutralize. Put the desizing fabric into a washing machine and rinse it several times...

Embodiment 2

[0051] The difference between Example 2 and Example 1 is that in S4 dyeing, the dispersant includes sodium dodecylbenzene sulfonate and sodium succinate, and the mass ratio of sodium dodecylbenzene sulfonate to sodium succinate is 7: 2.

Embodiment 3

[0052] The difference between Example 3 and Example 1 is that there is no dispersant in the dye in S4 dyeing.

[0053] The difference between embodiment 4-6 and embodiment 1 is that the scheduled time in S1 scheduled type is shown in the following table: Unit: min

[0054] Example Example 4 Example 5 Example 6 time44.35

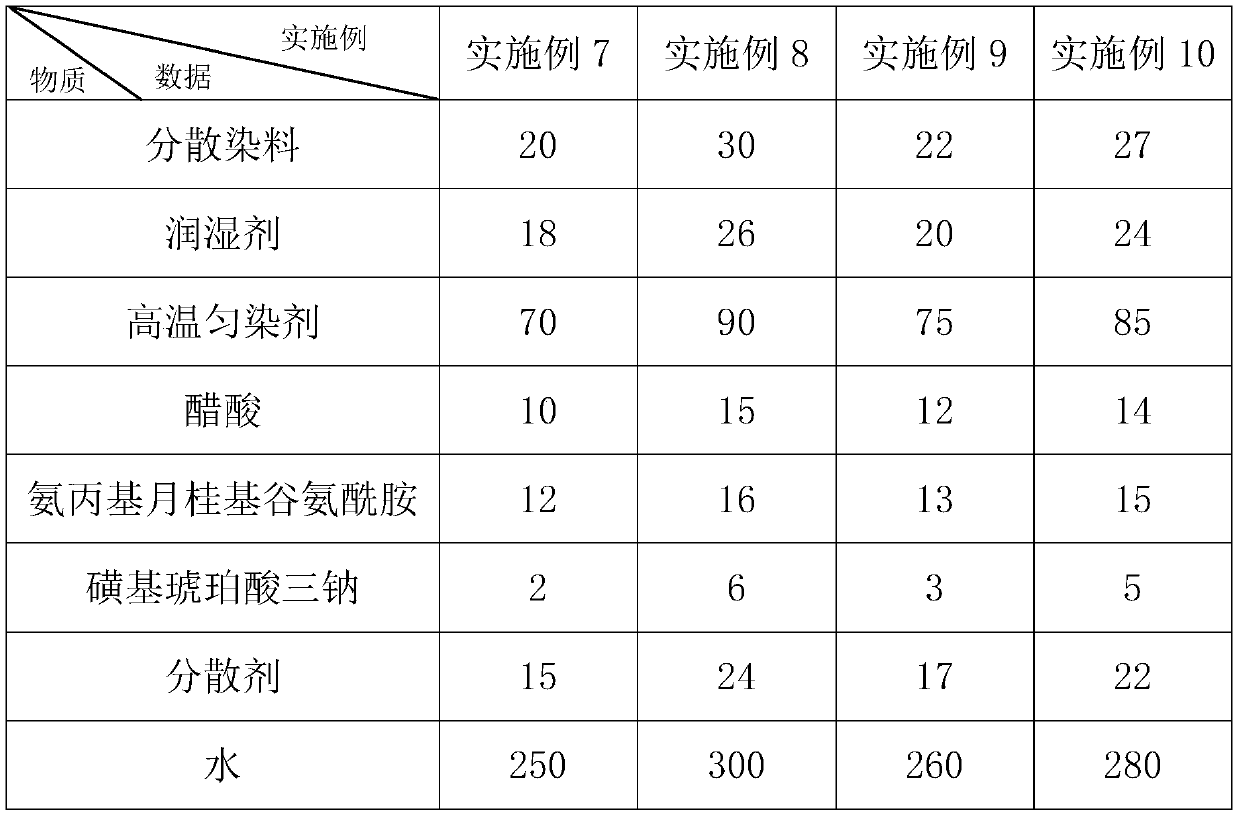

[0055] The difference between Examples 7-10 and Example 1 is that the chemical compositions of the dyes in S4 dyeing are in parts by weight as shown in the following table: Unit: parts

[0056]

[0057] The difference between Examples 11-13 and Example 1 is that the temperature of the dye liquor in S4 dyeing is shown in the following table: Unit: °C

[0058] Example Example 11 Example 12 Example 13 temperature100110120

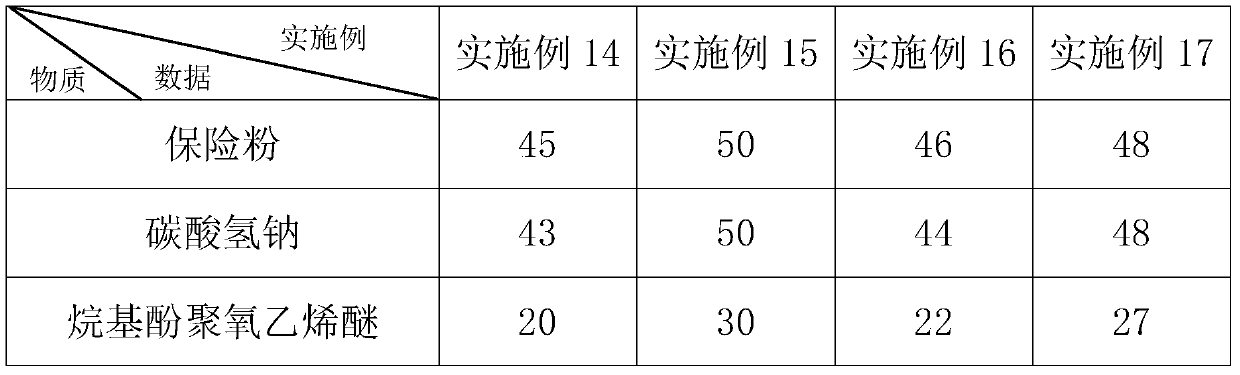

[0059] The difference between Examples 14-17 and Example 1 is that each substance of the reducing agent in step b in S5 washing is calculated in parts by weight as shown in the following table: Unit: parts

[0060]

[0061]

[0062] The diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com