Method for improving specific volume of an aluminum electrode foil by electrochemical deposition method

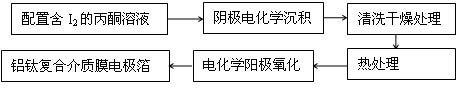

An aluminum electrode foil, electrochemical technology, applied in electrolytic capacitors, capacitor electrodes, capacitors and other directions, can solve the problems of preparing titanium-aluminum composite film, serious environmental pollution, long process cycle, etc., to achieve low industrial production cost and energy consumption, The effect of simple process flow and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

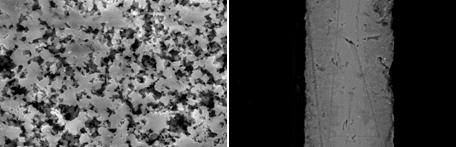

Embodiment 1

[0026] At room temperature, the I 2 The element is dissolved in acetone solution, I 2 The concentration in the acetone solution is 1g / L, the purity of acetone in the acetone solution is 99.5%, and the rest is water. Dry the cleaned metal titanium and aluminum corrosion foil until no moisture remains on the surface, and dip it in the above preparation in the shape of a pendant. In the organic electrolyte solution, the metal titanium is used as the positive electrode, and the aluminum corrosion foil is used as the negative electrode, which are respectively connected to the positive and negative electrodes of the DC stabilized voltage supply. The distance between the two electrodes is 10mm, and the electrochemical deposition is carried out. 35min at a temperature of 20°C.

[0027] The deposited aluminum foil was cleaned with deionized water, and then dried in an oven at 100°C.

[0028] The dried aluminum foil is heat-treated in the air atmosphere, the heat treatment tempera...

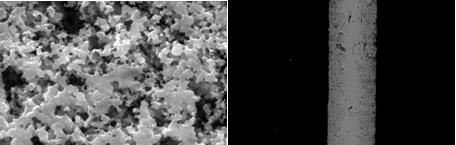

Embodiment 2

[0031] At room temperature, the I 2 The element is dissolved in acetone solution, I 2 The concentration in the acetone solution is 1.1g / L. The purity of acetone in the acetone solution is 99.2%, and the rest is water impurities. Dry the cleaned metal titanium and aluminum corrosion foil until there is no residual moisture on the surface, and dip it in the form of a pendant. In the organic electrolyte prepared above, the metal titanium is used as the positive electrode, and the aluminum corrosion foil is used as the negative electrode, which are respectively connected to the positive and negative electrodes of the DC stabilized voltage supply. The distance between the two electrodes is 5mm, and the electrochemical deposition is carried out. The time is 2min, the temperature is 30℃

[0032] The deposited aluminum foil was cleaned with deionized water, and then dried in an oven at 100°C.

[0033] The dried aluminum foil is heat-treated in the air atmosphere, the heat treatm...

Embodiment 3

[0036] At room temperature, the I 2 The element is dissolved in acetone solution, I 2 The concentration in the acetone solution is 1g / L, the purity of acetone is 99.8%, and the rest is water. Dry the cleaned metal titanium and aluminum corrosion foil until there is no residual moisture on the surface, and dip it in the above prepared organic electrolysis foil in the shape of a pendant. In the solution, the metal titanium is used as the positive electrode, and the aluminum corroded foil is used as the negative electrode, which are respectively connected to the positive and negative electrodes of the DC regulated power supply. The distance between the two electrodes is 20mm, and the electrochemical deposition is carried out. is 0°C.

[0037] The deposited aluminum foil was cleaned with deionized water, and then dried in an oven at 100°C. The dried aluminum foil is heat-treated in the air atmosphere, the heat treatment temperature is 700 ° C, and the heat treatment time is 15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com