Method for preparing poly crystal germanium silicon film

A technology of silicon thin film and polycrystalline germanium, which is applied in the field of preparation of polycrystalline silicon germanium thin film, can solve the problems of poor crystal quality, low carrier mobility, and many defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Clean the silicon substrate and put it into a thermal oxidation furnace, feed oxygen with a purity of 99.99%, and thermally oxidize a layer of 0.2 μm silicon dioxide at 1000°C;

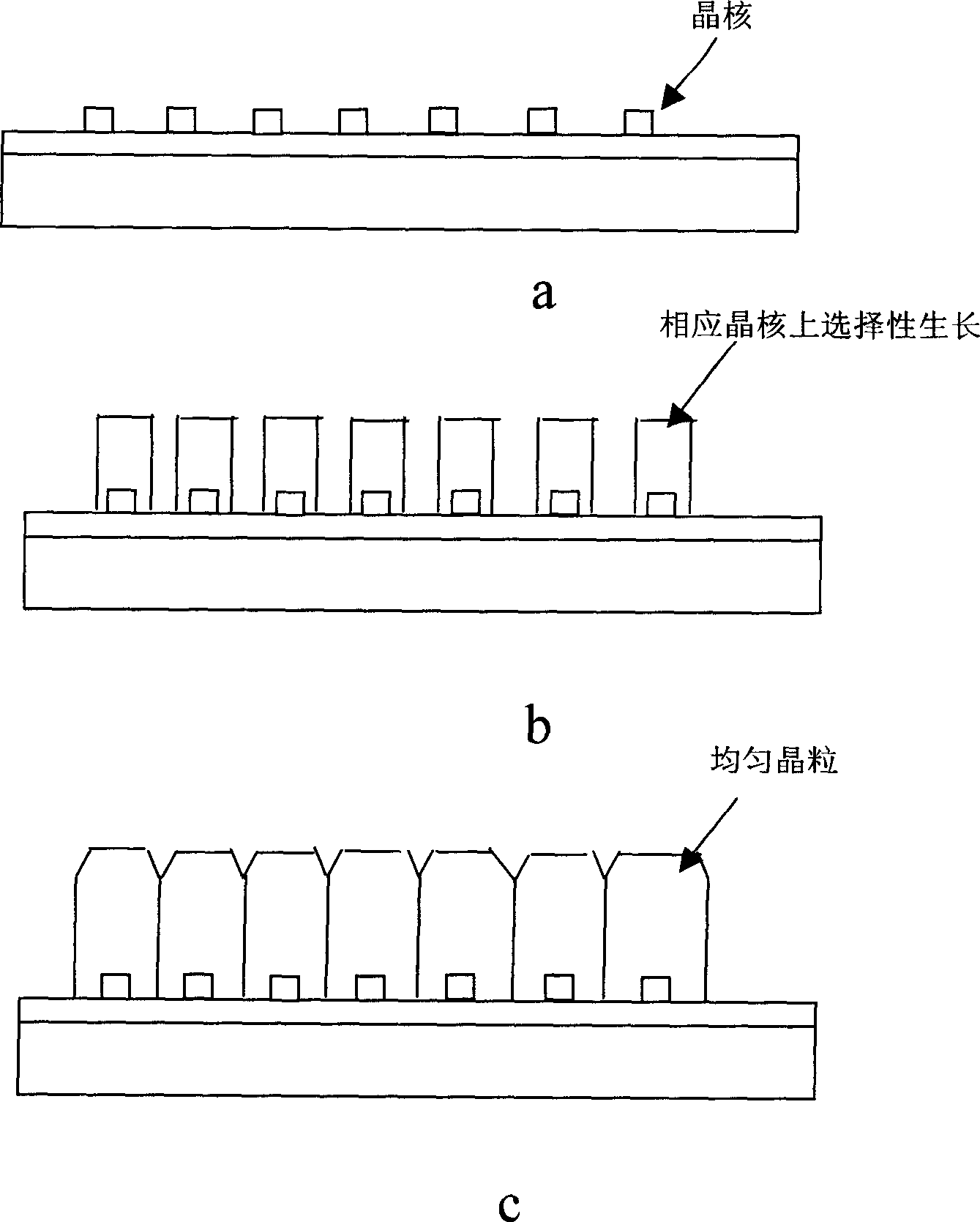

[0015] 2) Put the sample into an ultra-high vacuum chemical vapor deposition system, and at 550°C, feed silane with a purity of 99.999% and a mixed gas of germane and hydrogen with a germane content of 10%, and control the flow of the silane and mixed gas The ratio is 5:5, the pressure in the growth chamber is 10Pa, and the growth takes 15 minutes to form silicon germanium crystal nuclei on the surface of silicon dioxide, as shown in Figure 1a;

[0016] 3) Reduce the growth pressure in the growth chamber to 0.01Pa, keep the temperature at 550°C and the flow ratio of silane and mixed gas at 5:5, and selectively grow at the SiGe crystal nucleus (see Figure 1b) for 20 minutes Finally, a polycrystalline silicon germanium thin film with uniform crystal quality in the growth direction is obtained....

Embodiment 2

[0018] 1) Clean the silicon substrate and put it into a thermal oxidation furnace, feed oxygen with a purity of 99.99%, and thermally oxidize a layer of 0.3 μm silicon dioxide at 1000°C;

[0019] 2) Put the sample into an ultra-high vacuum chemical vapor deposition system, and at 600°C, feed disilane with a purity of 99.999% and a mixed gas of germane and hydrogen with a germane content of 10%, and control the disilane and mixed gas The flow rate ratio is 5:5, the pressure in the growth chamber is 20Pa, and the growth time is 10 minutes, forming silicon germanium crystal nuclei on the surface of silicon dioxide;

[0020] 3) Reduce the growth pressure in the growth chamber to 0.1Pa, keep the temperature at 600°C and the flow ratio of disilane and mixed gas at 5:5, and selectively grow at the silicon germanium nucleus. After 30 minutes of growth, the obtained Polycrystalline silicon germanium film with uniform crystal quality in the growth direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com