Patents

Literature

59 results about "Germanium crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

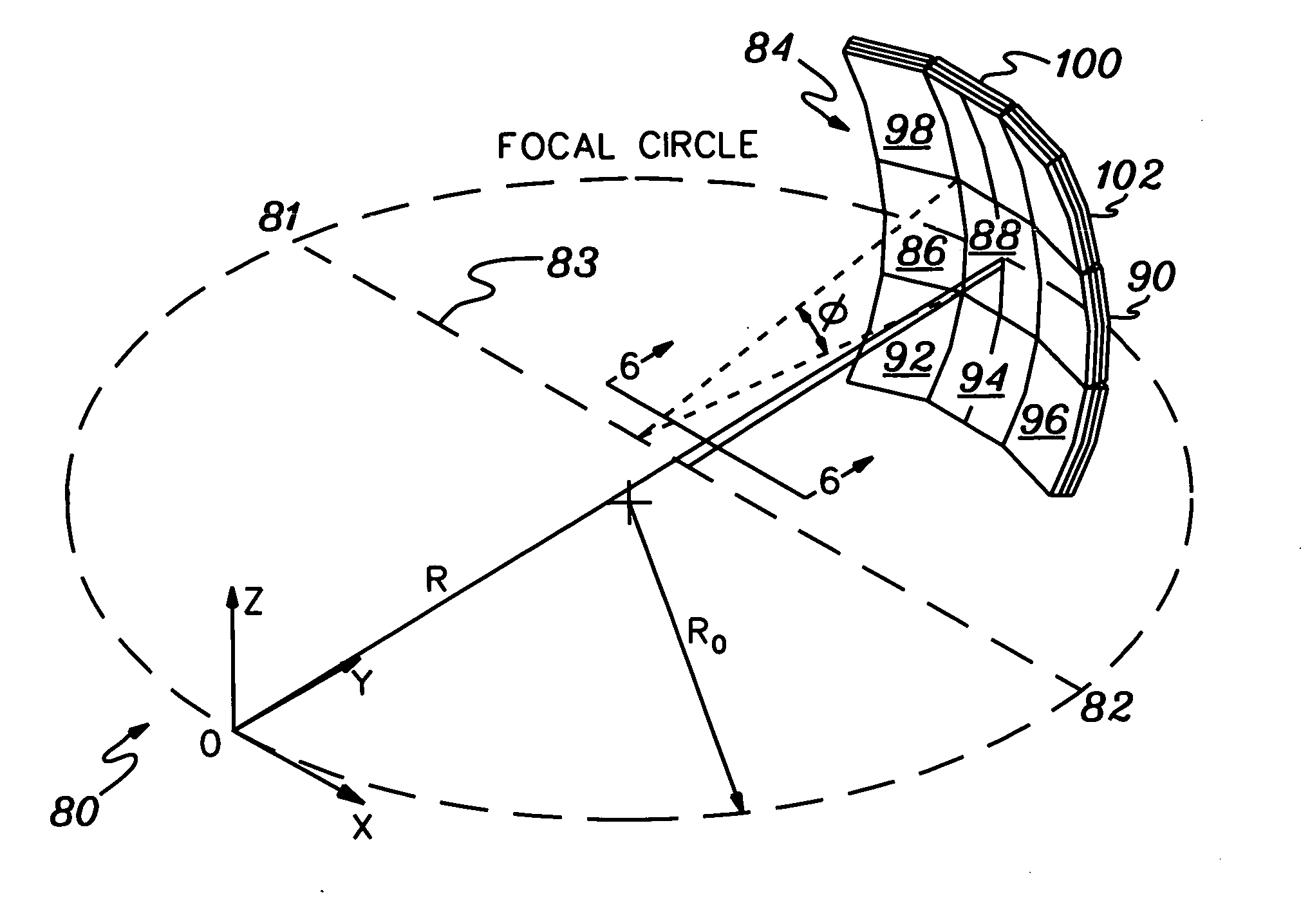

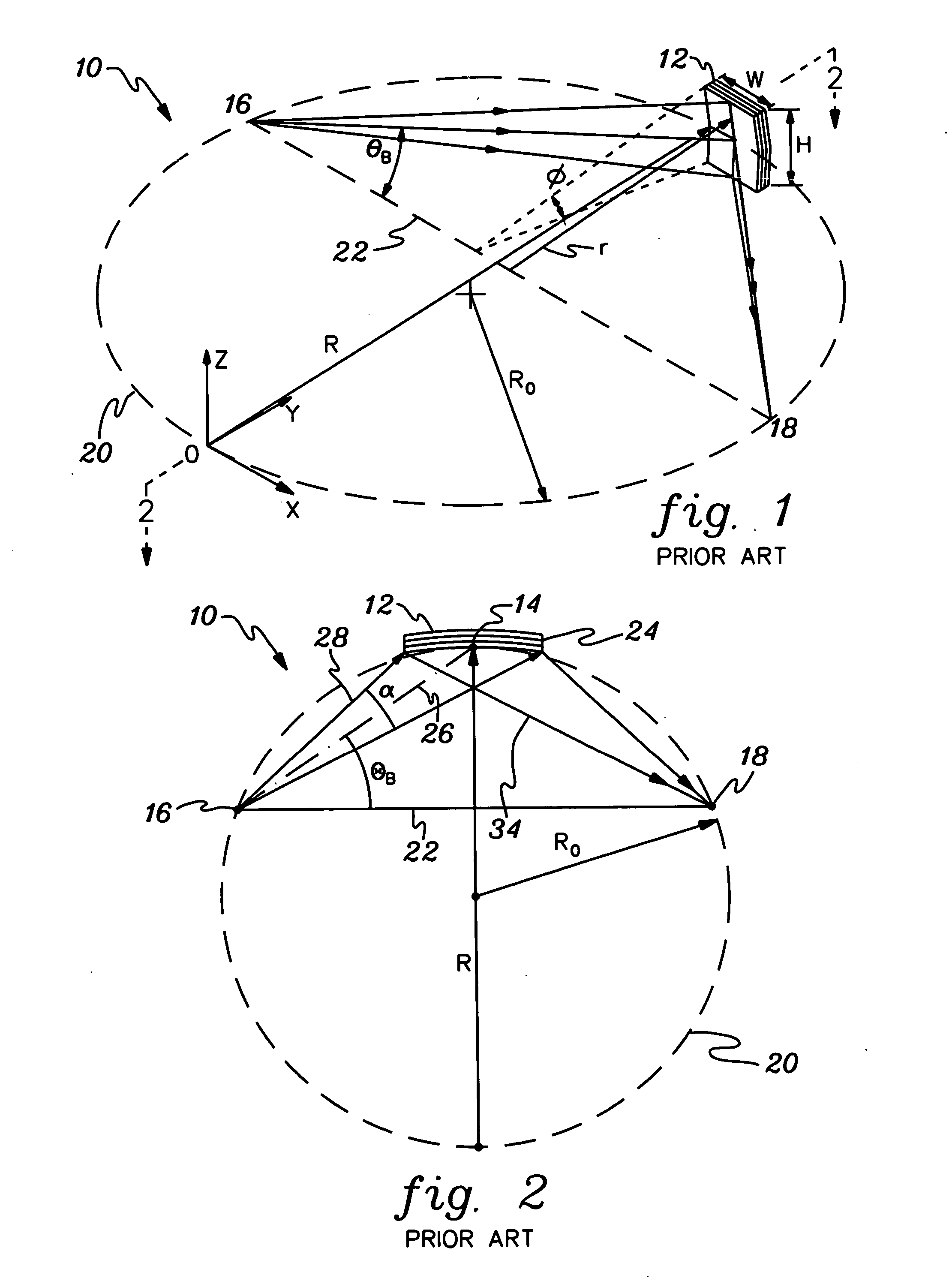

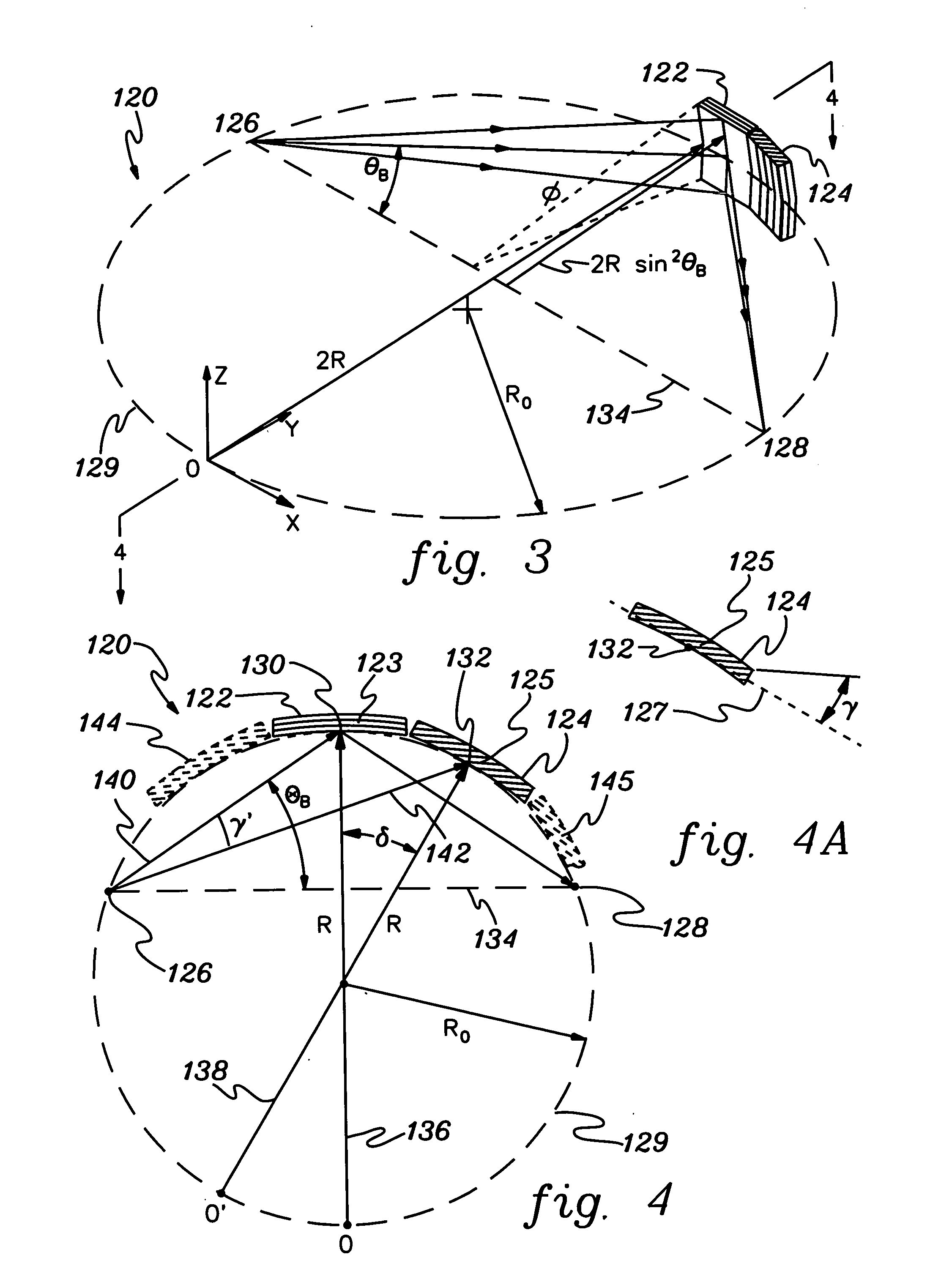

Optical device for directing x-rays having a plurality of optical crystals

InactiveUS7035374B2Material analysis using wave/particle radiationHandling using diffraction/refraction/reflectionSoft x rayHigh energy

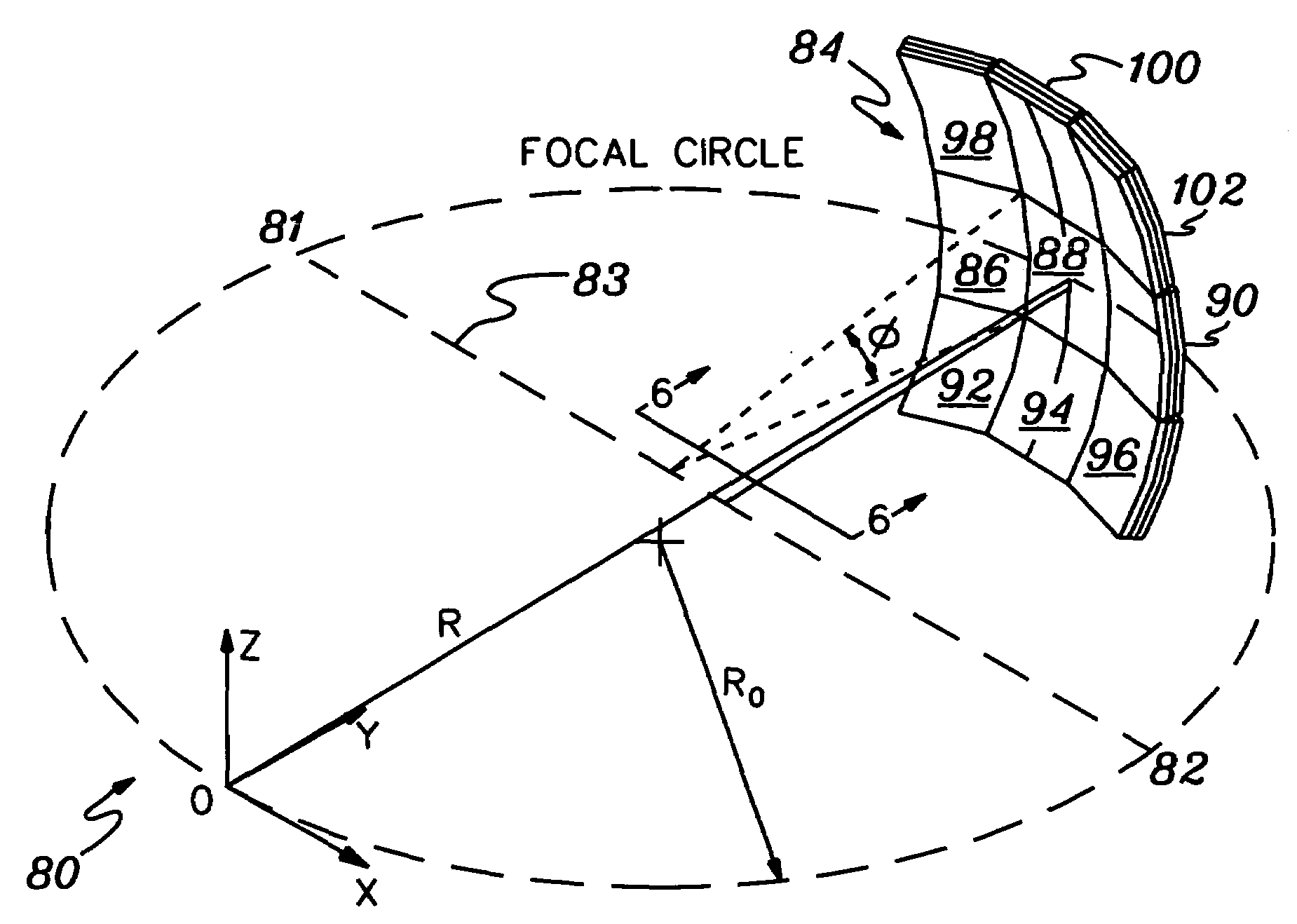

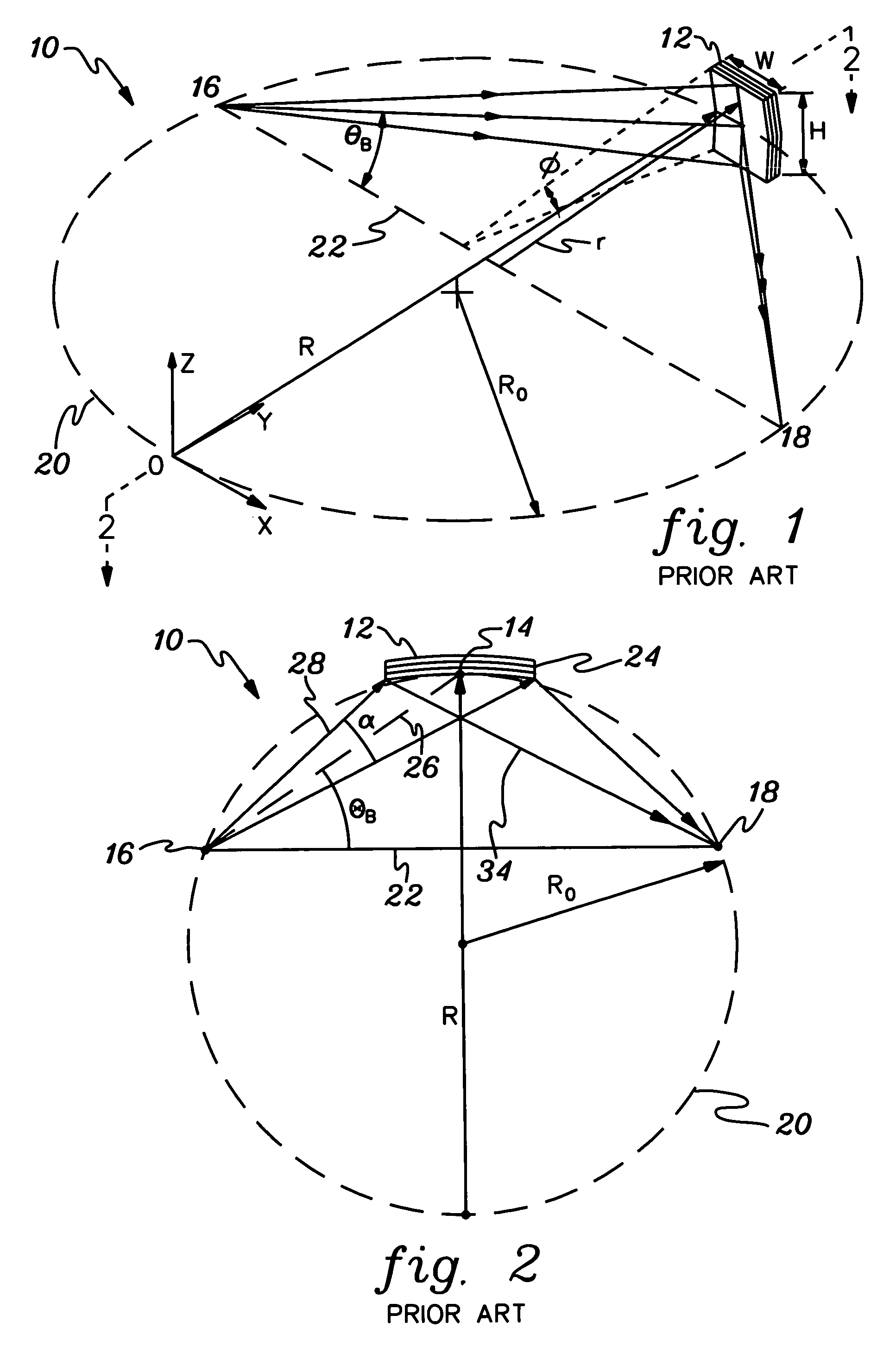

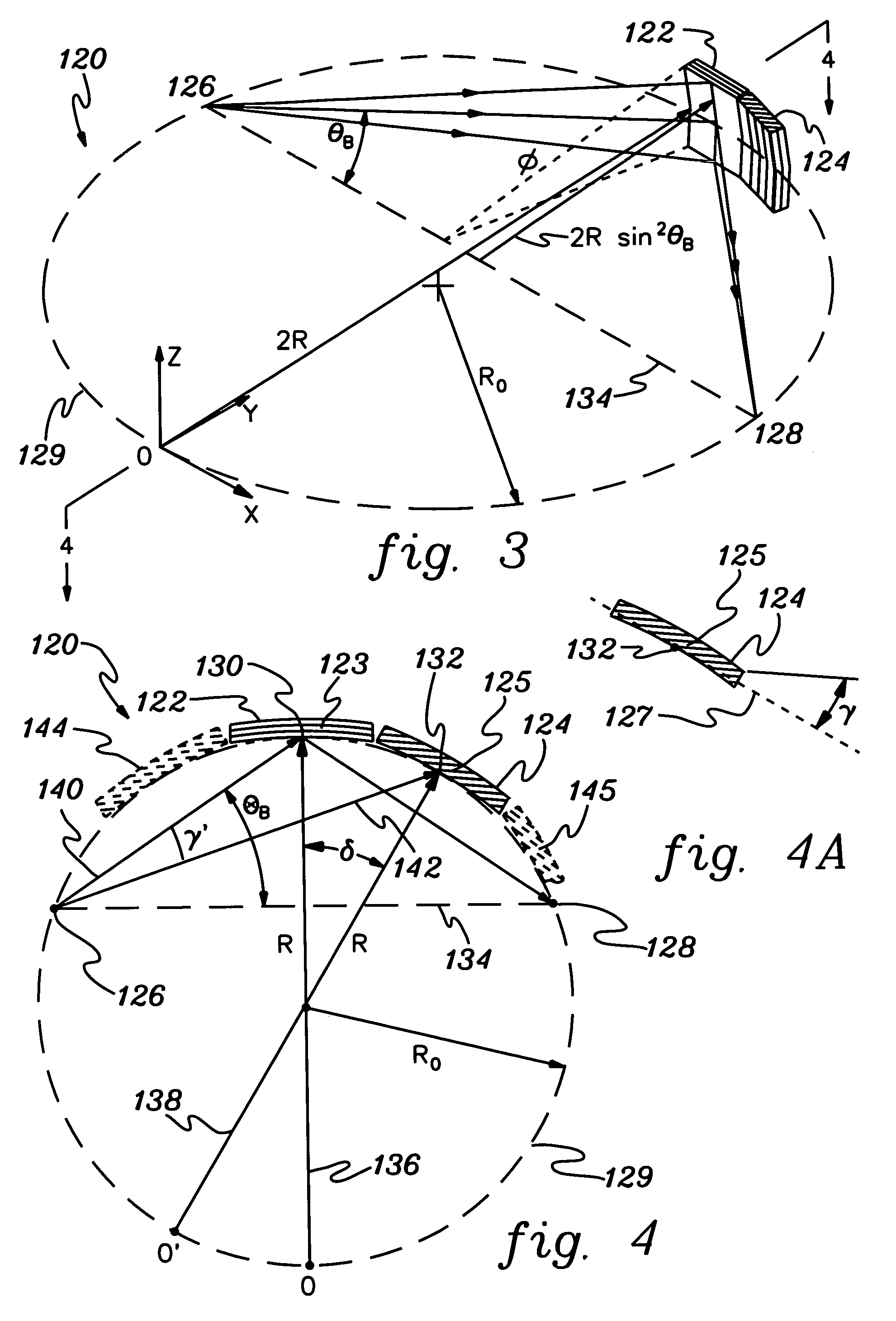

Devices for improving the capturing and utilization of high-energy electromagnetic radiation, for example, x-rays, gamma rays, and neutrons, for use in physical, medical, and industrial analysis and control applications are disclosed. The devices include optics having a plurality of optical crystals, for example, doubly-curved silicon or germanium crystals, arranged to optimize the capture and redirection of divergent radiation via Bragg diffraction. In one aspect, a plurality of optic crystals having varying atomic diffraction plane orientations are used to capture and focus divergent x-rays upon a target. In another aspect, a two- or three-dimensional matrix of crystals is positioned relative to an x-ray source to capture and focus divergent x-rays in three dimensions.

Owner:X-RAY OPTICAL SYSTEM INC

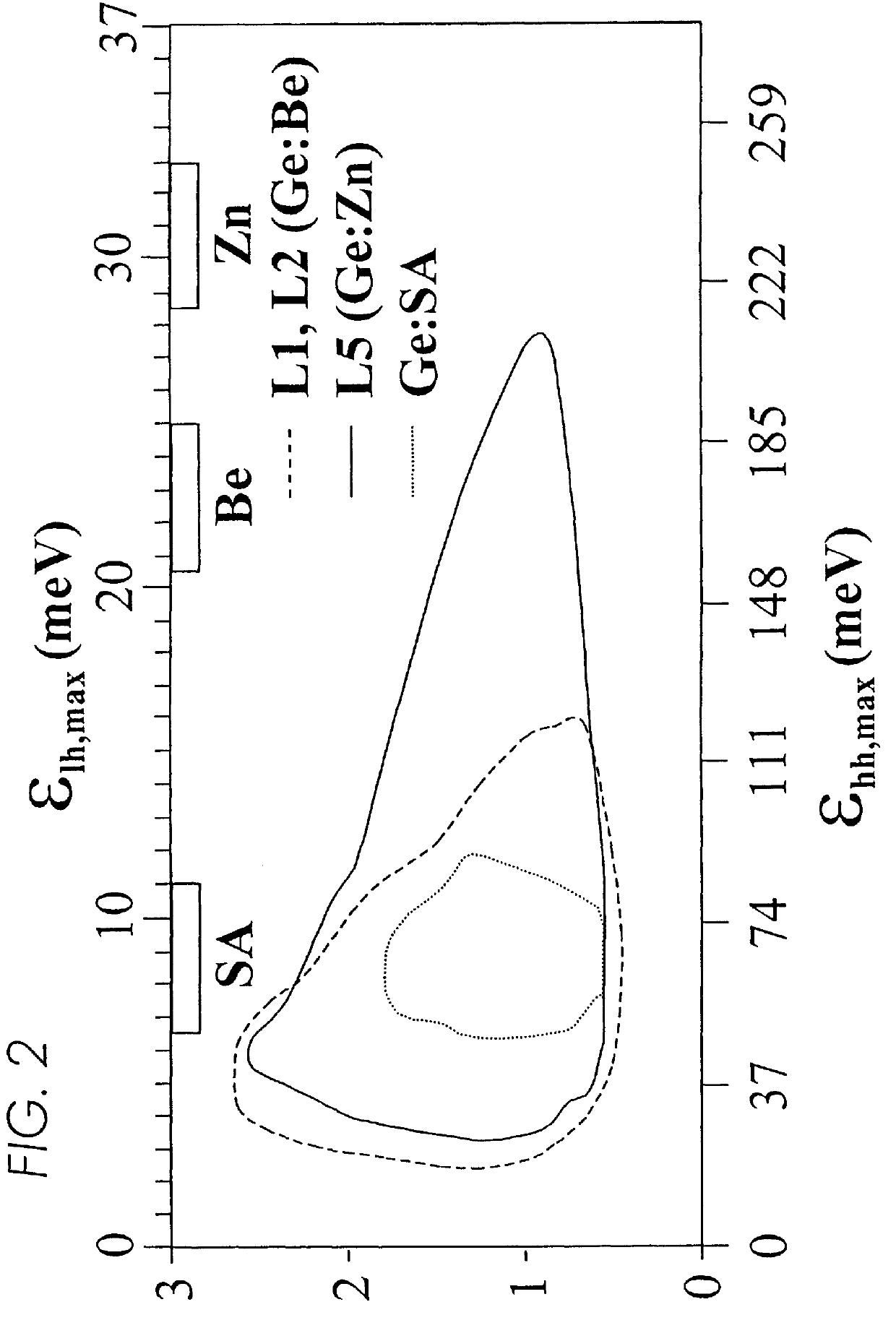

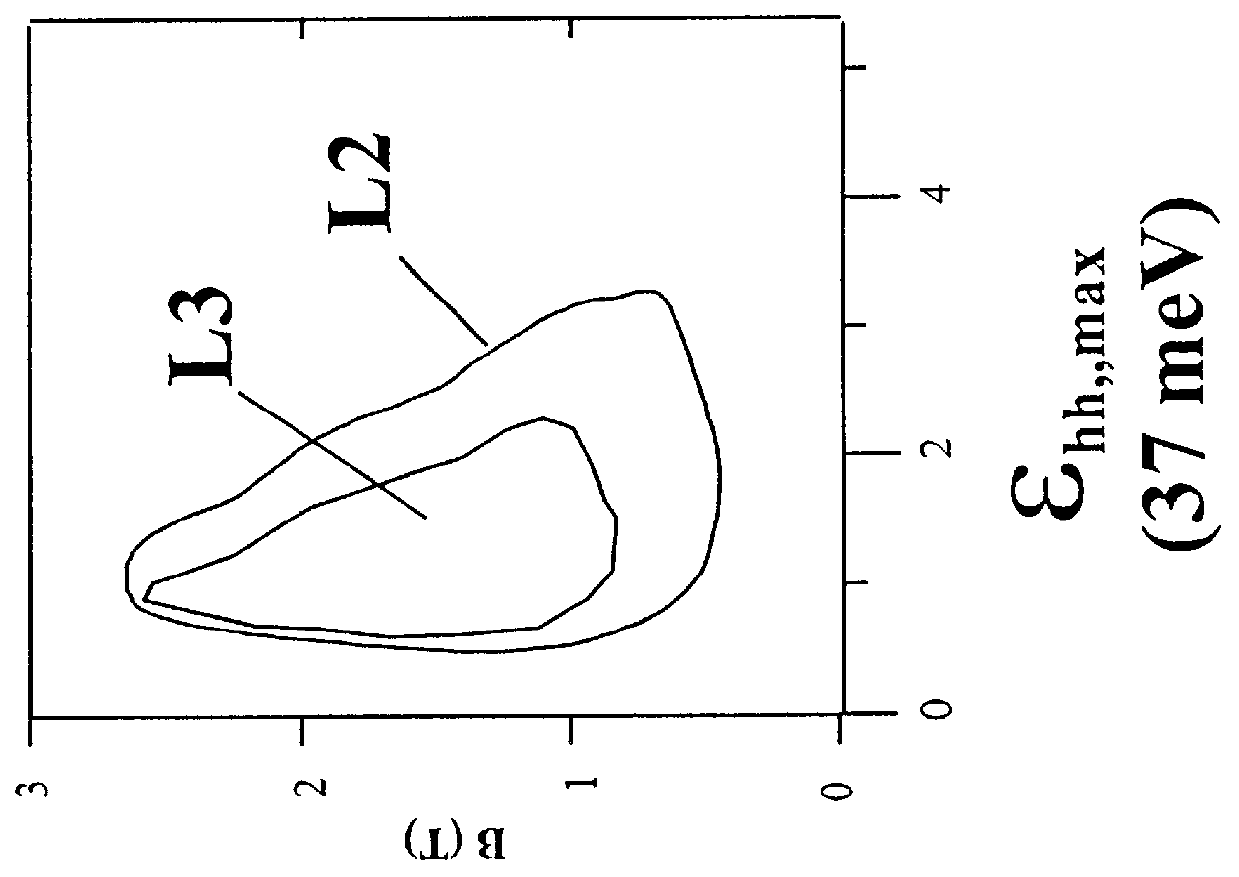

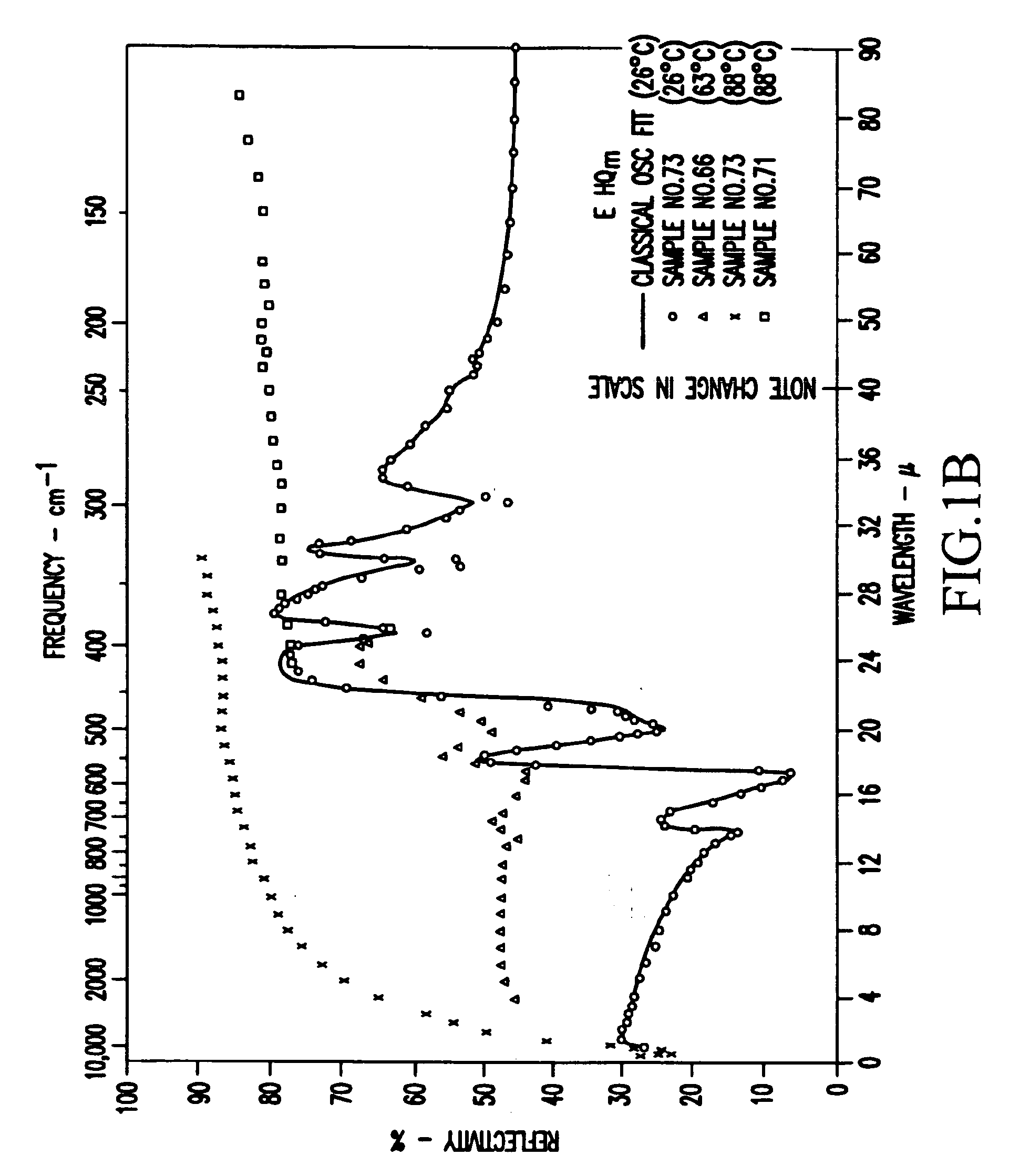

Doping of germanium and silicon crystals with non-hydrogenic acceptors for far infrared lasers

InactiveUS6011810AIncrease powerHigh duty cycleLaser detailsLaser active region structureAcceptor dopantFar infrared

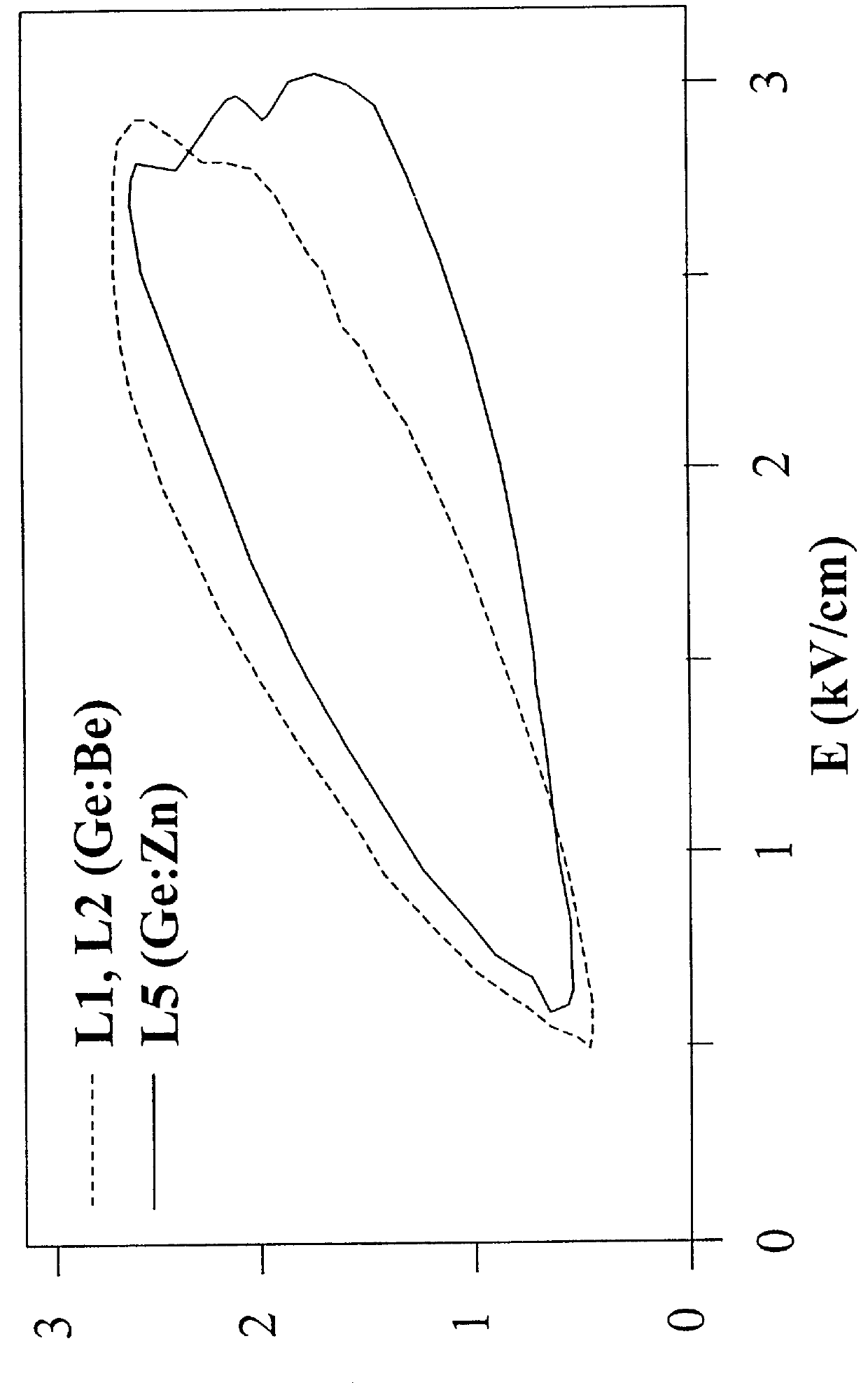

A method for doping semiconductors used for far infrared lasers with non-hydrogenic acceptors having binding energies larger than the energy of the laser photons. Doping of germanium or silicon crystals with beryllium, zinc or copper. A far infrared laser comprising germanium crystals doped with double or triple acceptor dopants permitting the doped laser to be tuned continuously from 1 to 4 terahertz and to operate in continuous mode. A method for operating semiconductor hole population inversion lasers with a closed cycle refrigerator.

Owner:LAWRENCE BERKELEY NAT LAB

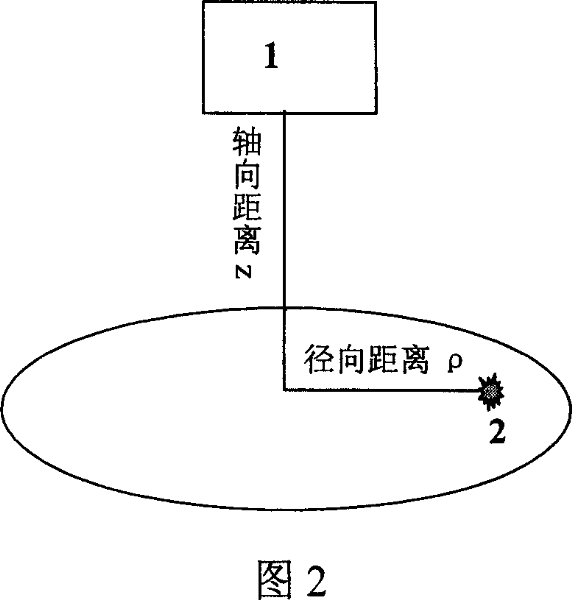

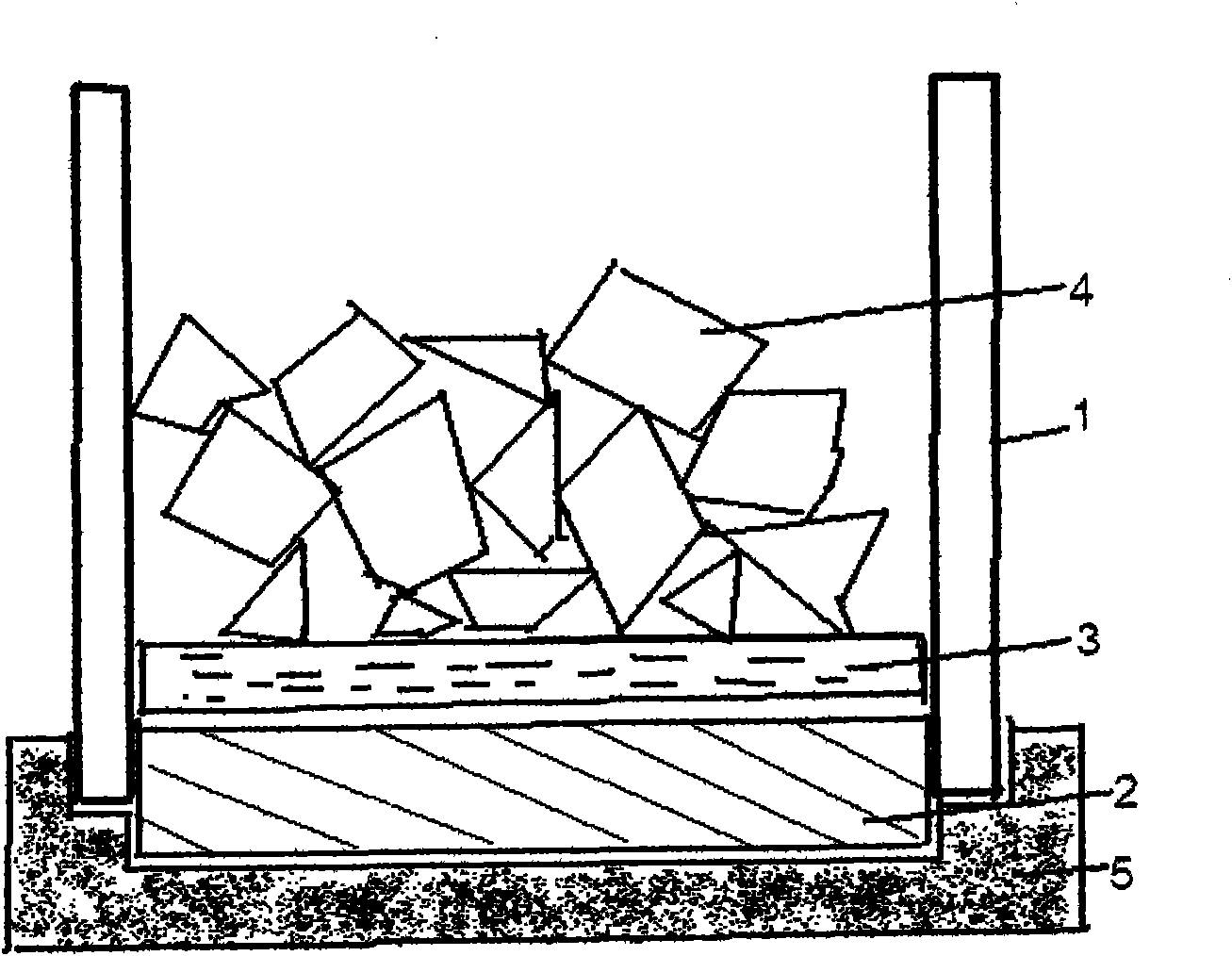

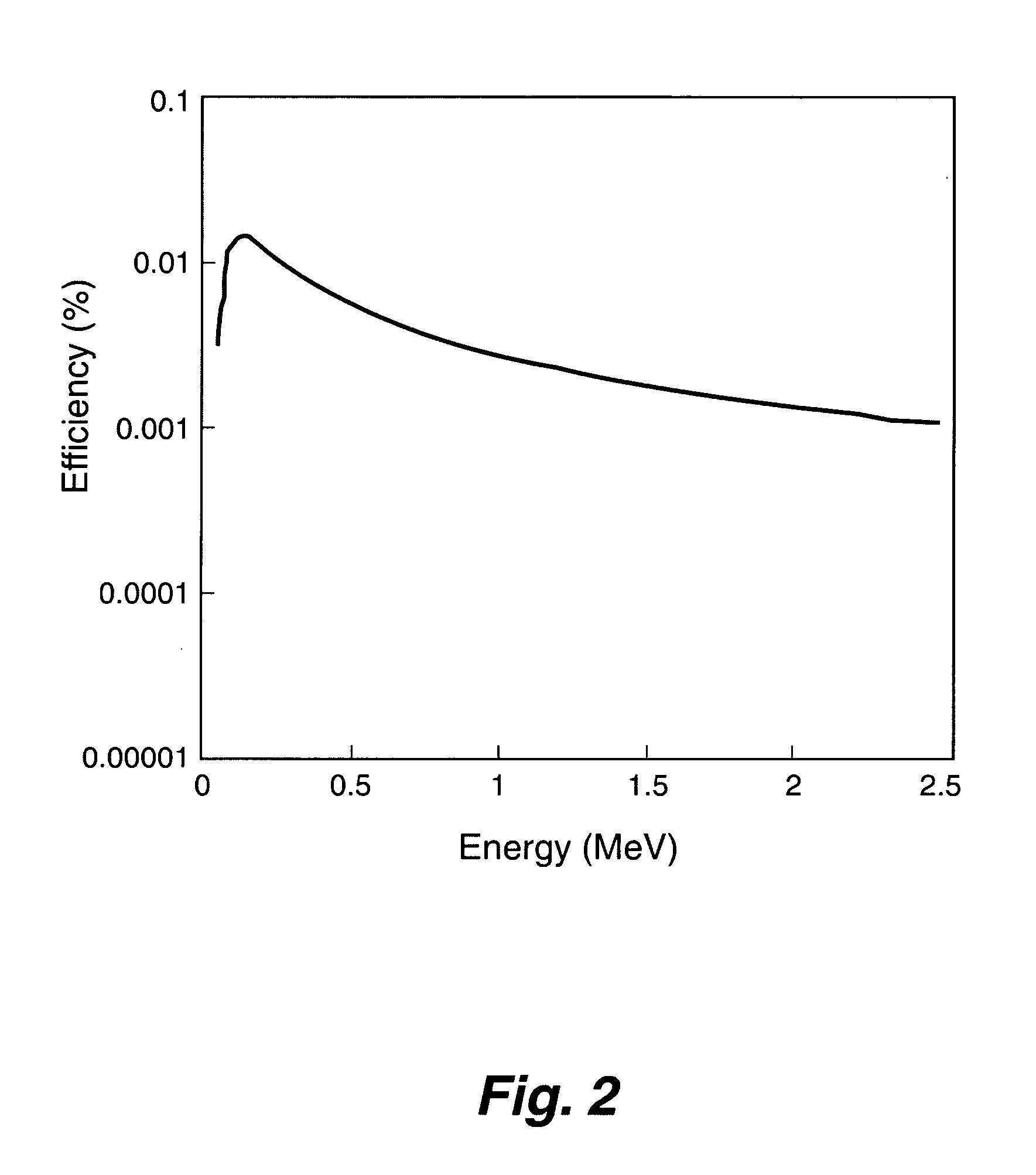

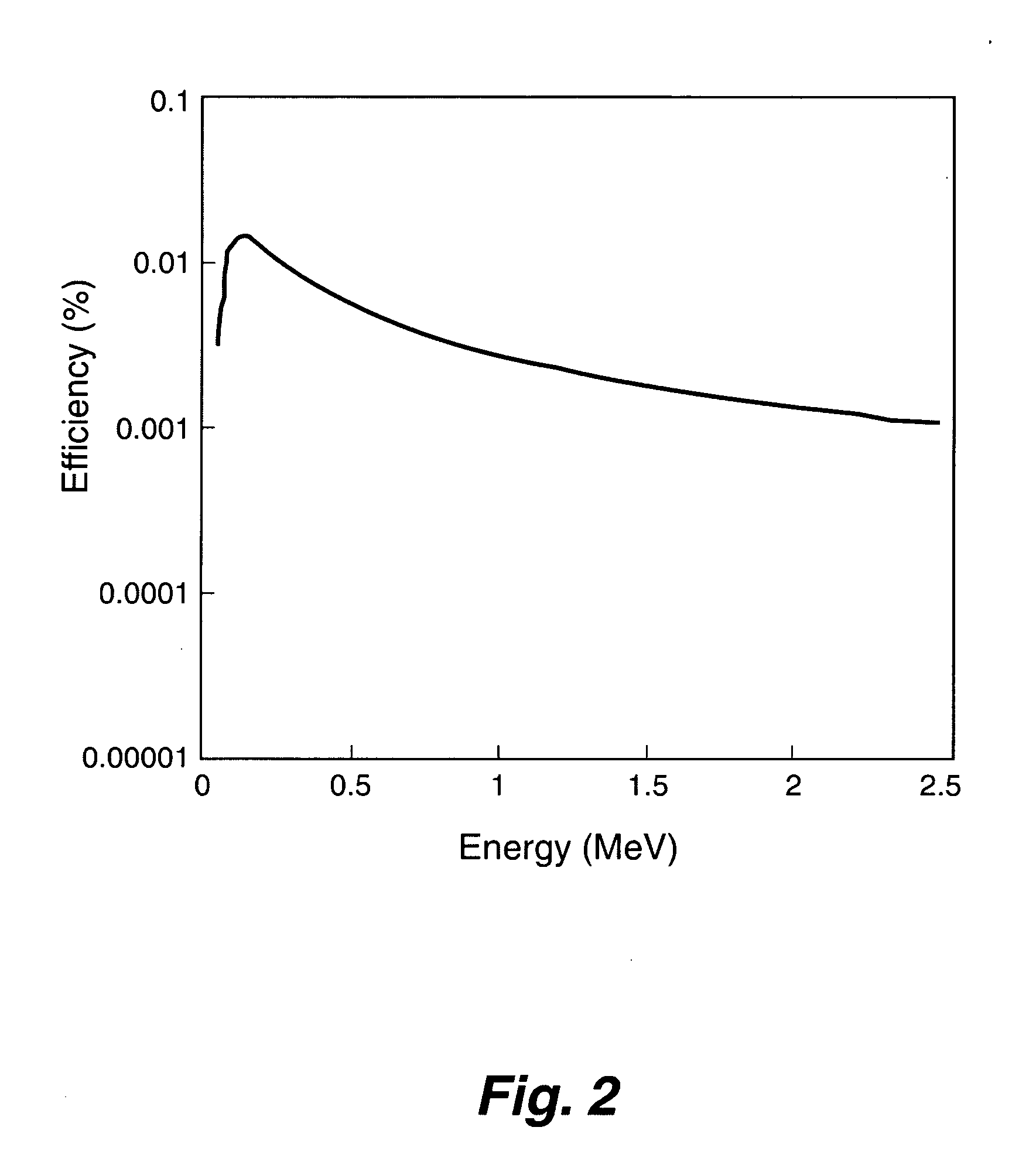

Method of high-purity germanium detector efficiency calibration without a radioactive source

ActiveCN101038261AAccurately determineAutomatically determinedMaterial analysis using wave/particle radiationX/gamma/cosmic radiation measurmentRadioactive wasteRadioactive source

The present invention relates to a method for a high purity germanium detector efficiency calibration without a radioactive source. Said method is capable of automatically, quickly and correctly ascentaining a high purity germanium crystal and its sensitive region size, then directly performing a simulation calculation adopting a monte carlo method, and then quickly achieving the high purity germanium detector efficiency calibration without a radioactive source.

Owner:CHINA INST FOR RADIATION PROTECTION

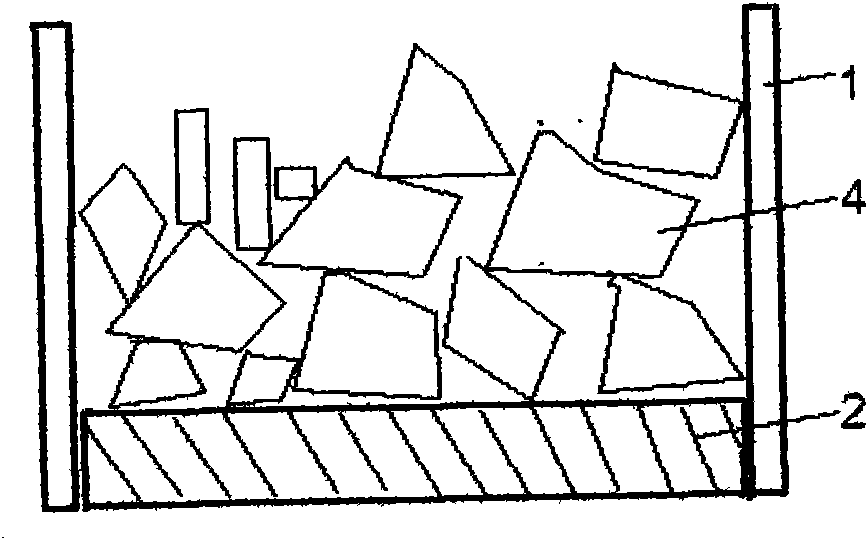

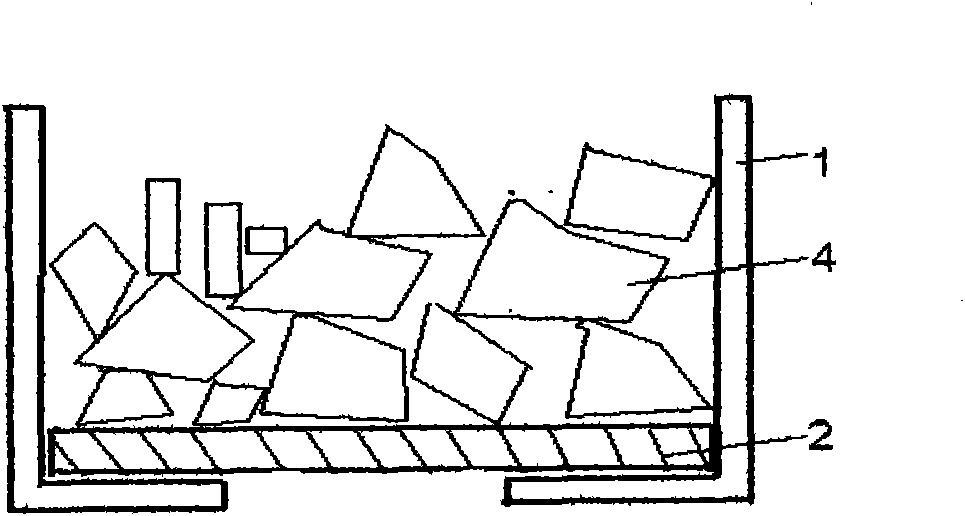

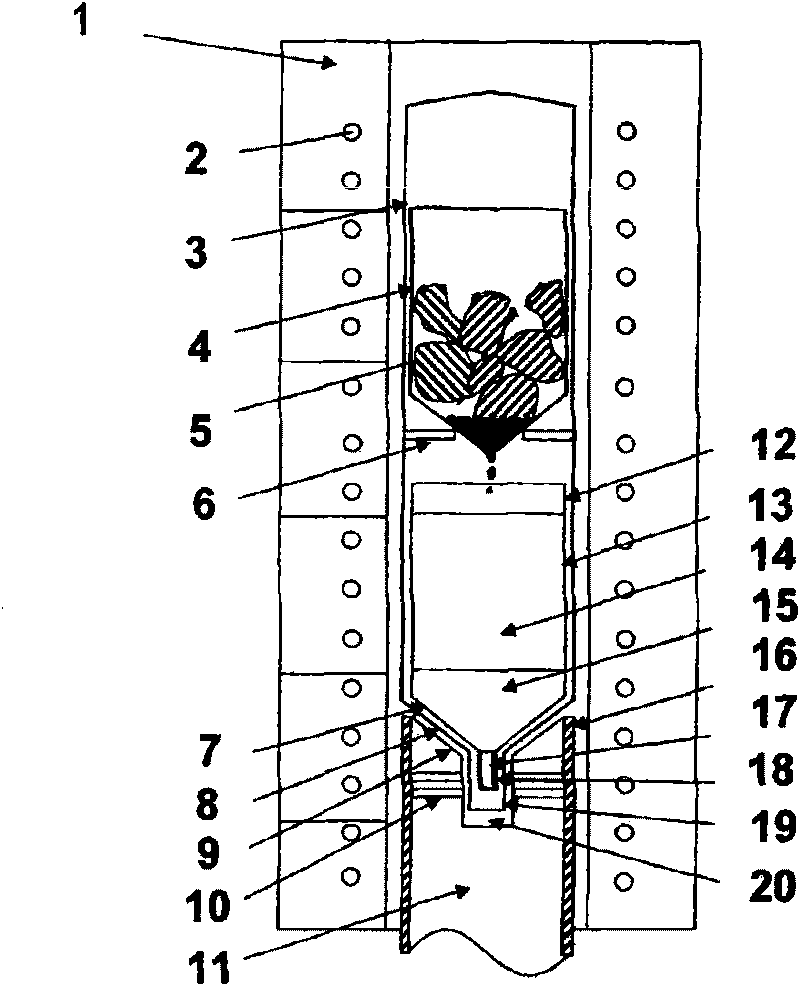

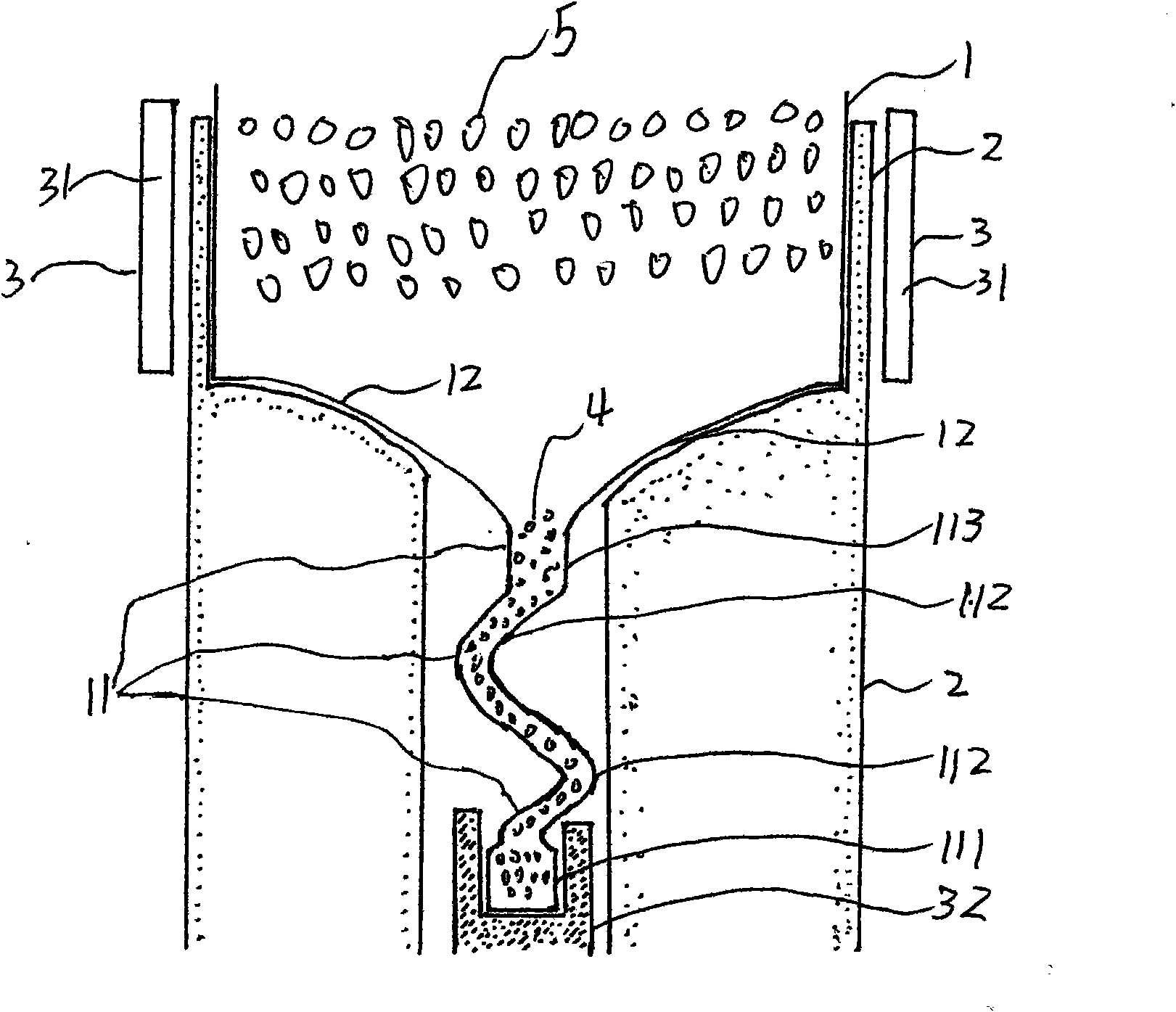

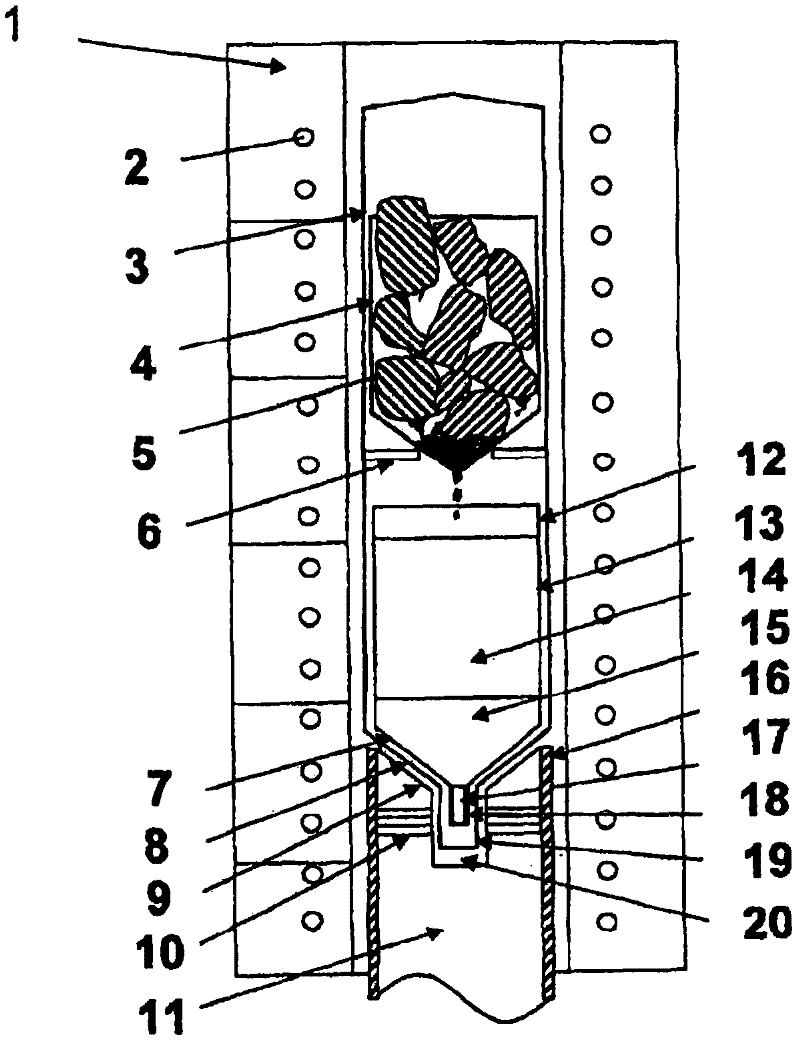

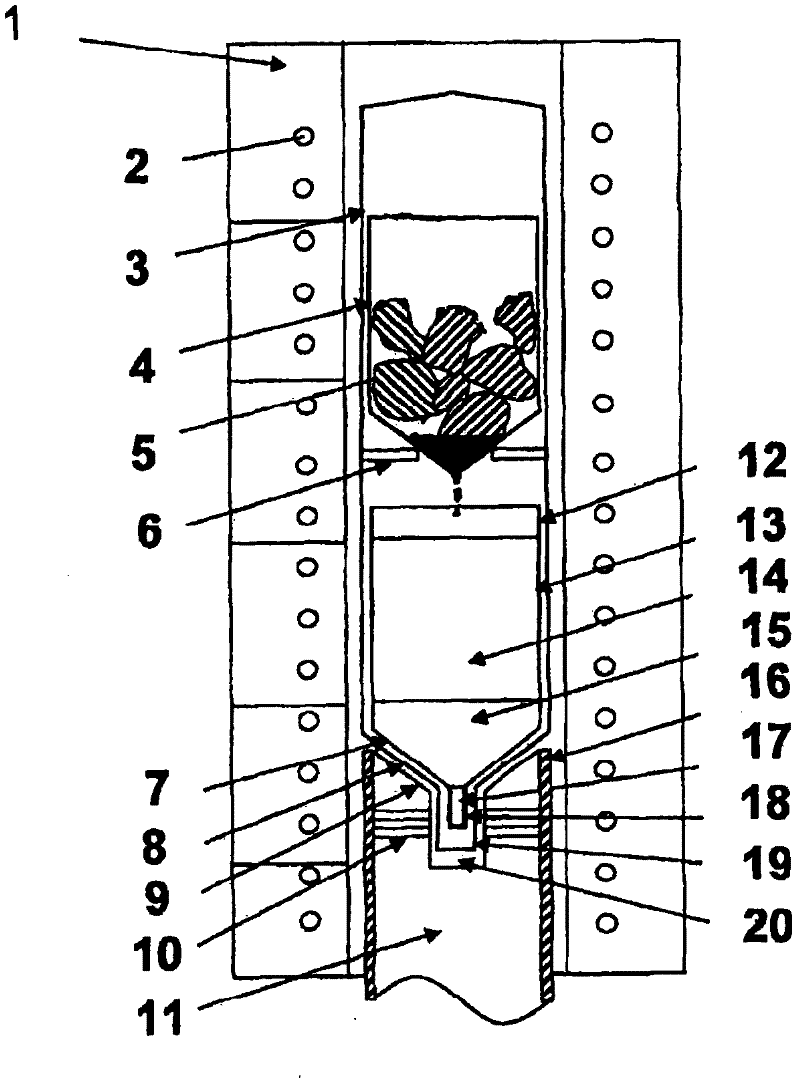

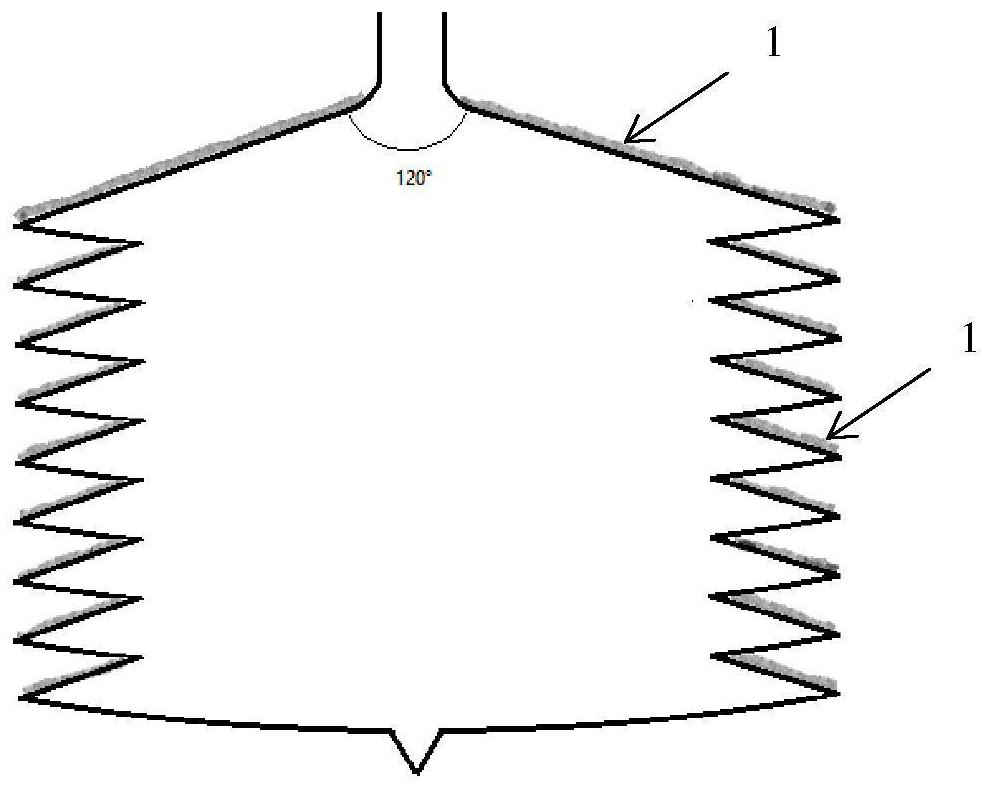

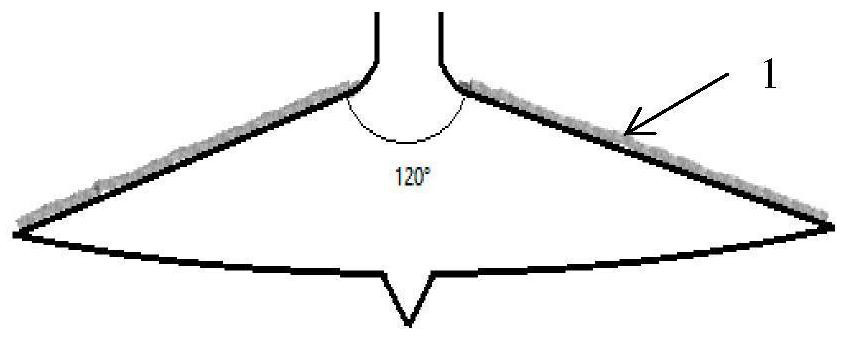

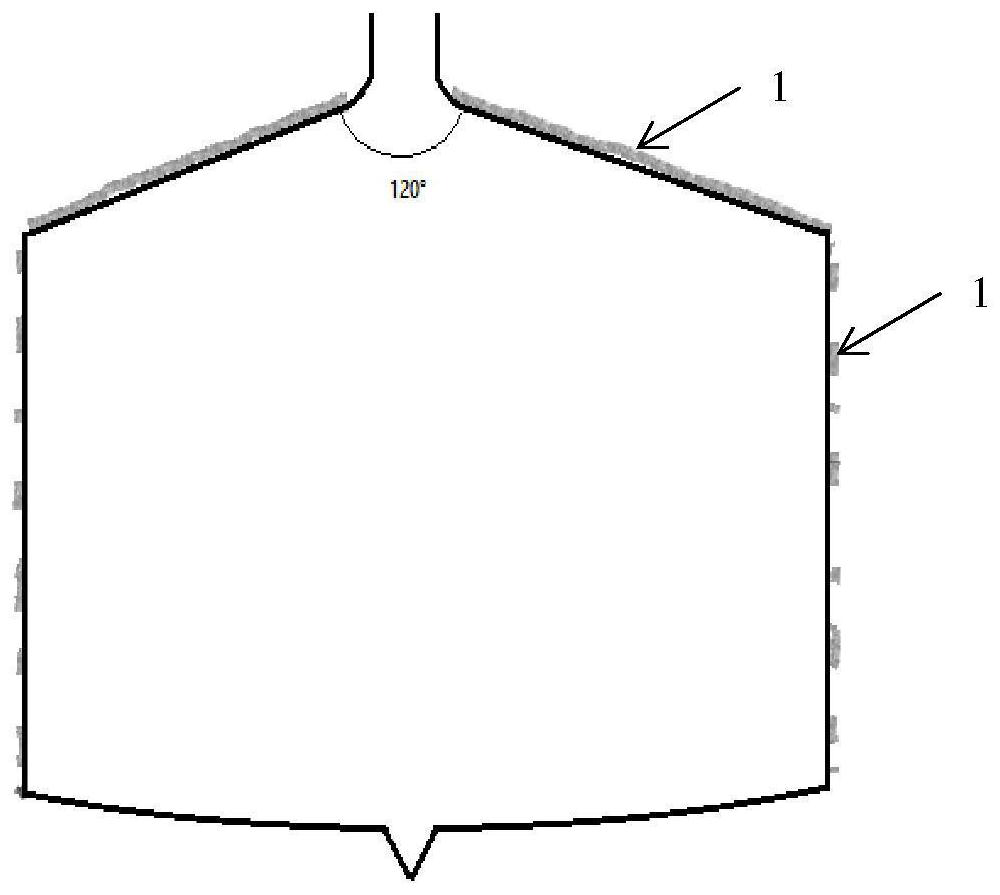

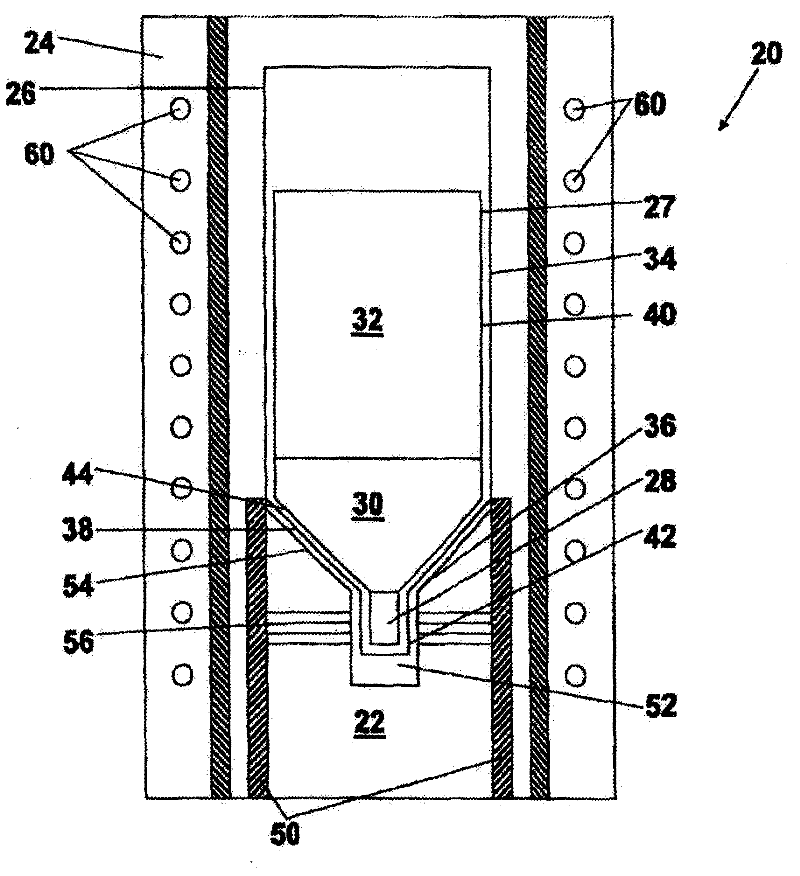

Crystal, and method and device for casting same

InactiveCN102383184APolycrystalline material growthFinal product manufactureThermal insulationHigh energy

The invention generally relates to a crystal casting method using seed crystals, such as a directional solidification casting method. The crystal casting method includes a temperature gradient solidification method for manufacturing larger crystal materials in preset crystal orientation, wherein the crystal materials include polycrystalline materials and monocrystalline materials, and particularly include silicon or silicon germanium materials applicable to semiconductor and photovoltaic application. An existing crystal casting method using seed crystals has the problems of high energy consumption, more control difficulty, more impurity particles, easiness in generating mixed crystals, difficulty in obtaining large-sized monocrystalline materials and the like. The crystal casting method solves the problems by the aid of a bottomless crucible or a crucible with a notch at the bottom, a heat insulation area and a heat insulation position, fine crystal growth effect is achieved, the obtained casting monocrystalline or polycrystalline materials such as silicon or silicon germanium crystals have fewer defects or impurities, fine quality and excellent performance, and are applicable to the semiconductor and photovoltaic field.

Owner:赵钧永

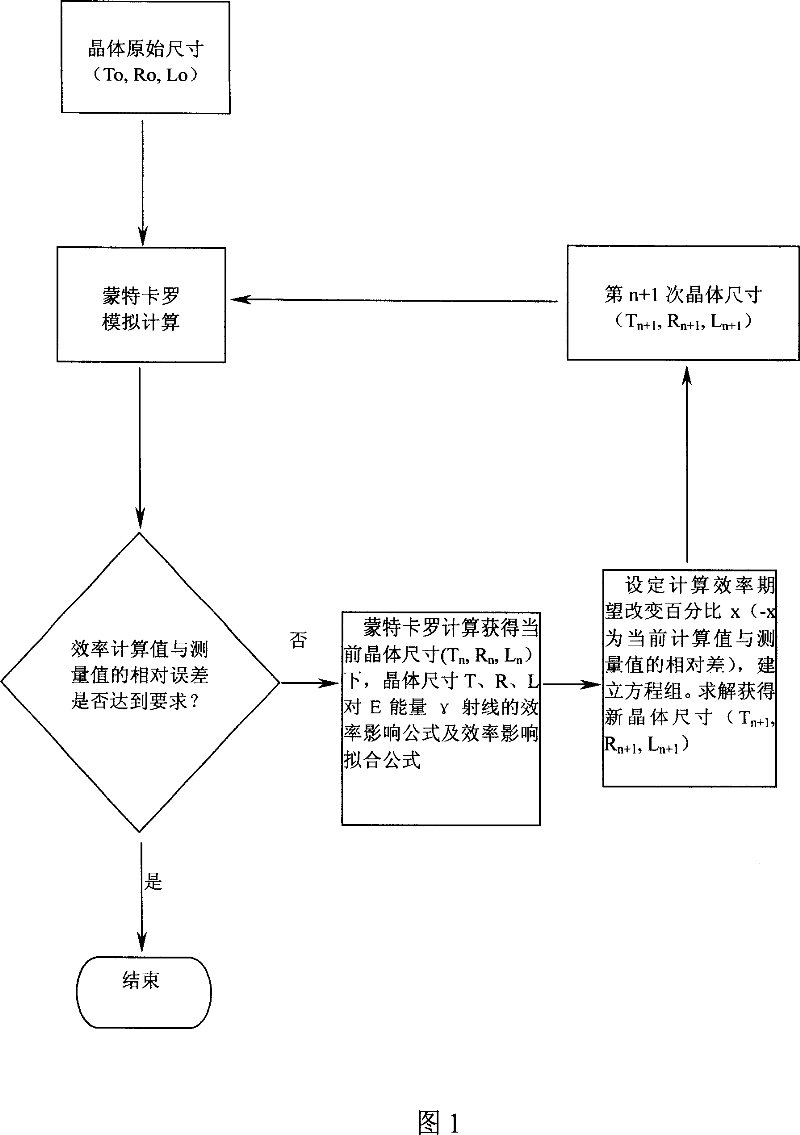

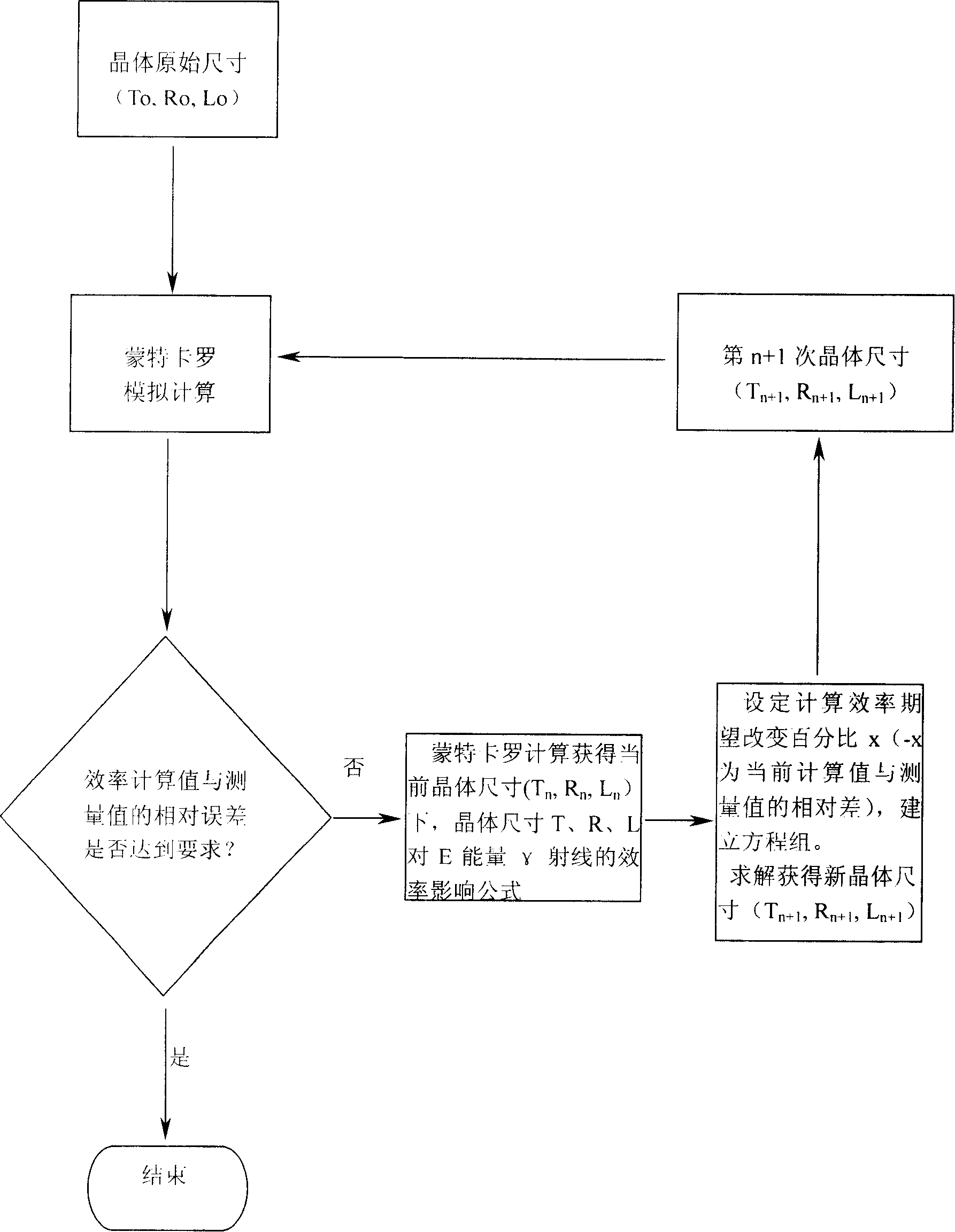

Germanium crystal dimension automatic regulation method for high-purity germanium detector passive efficiency scale division

InactiveCN101162269AAccurately determineAutomatically determinedRadiation intensity measurementSemiconductor devicesGermanium crystalPhysics

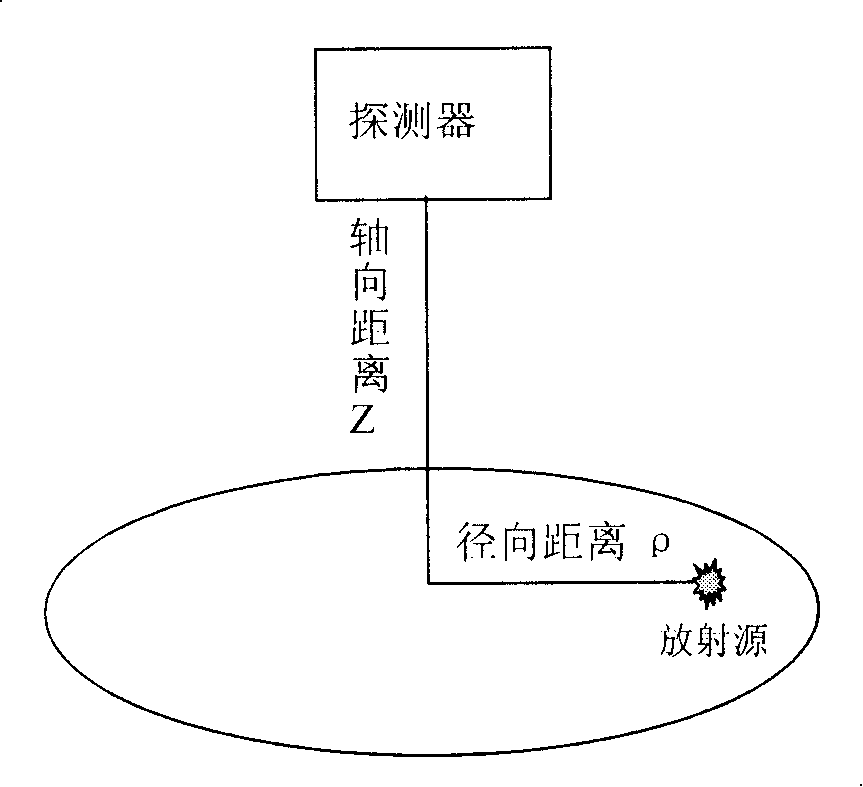

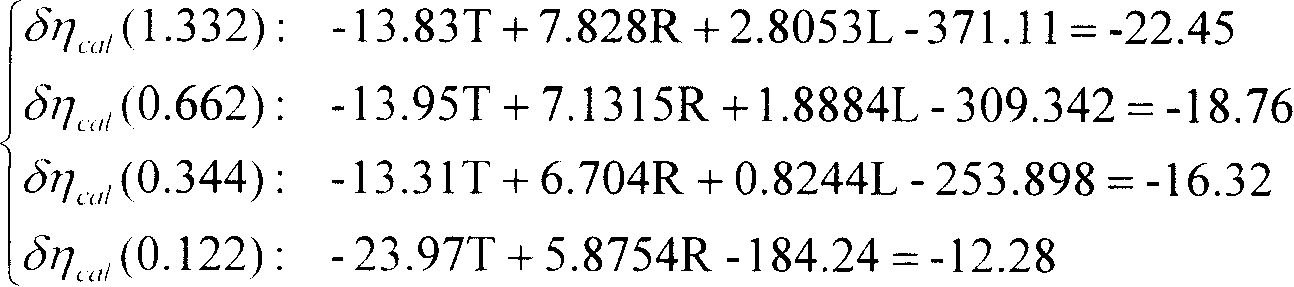

The invention relates to radiation measuring technical field, specifically to a germanium crystal size automatic adjustment method with souceless efficiency calibration used in high-purity germanium detector, wherein, a plurality of measuring values of gamma radial omnipotence peak testing efficiency of different Ei energies can be obtained at one testing position, and then the computing valves of all gamma radial omnipotence peak testing efficiency of different Ei can be attained through Monte Carlo analog computation according to the original size of crystal provided by the product instruction of the detector; and error analysis is performed on the efficiency computing value and the measuring value, an efficiency influence formula of the crystal sizes T, R, L on E-energy gamma radial can be calculated under the present crystal sizes through Monte Carlo calculation; a computational efficiency expecting change percentage is set, and an equation group is built to get the size of a new crystal, a final result can be got by repeating the above procedures. The invention can automatically, quickly, accurately determine a high-purity germanium crystal and the size of the sensitive area to effectively ensure the realization of quick Monte Carlo souceless efficiency calibration for high-purity germanium detector.

Owner:CHINA INST FOR RADIATION PROTECTION

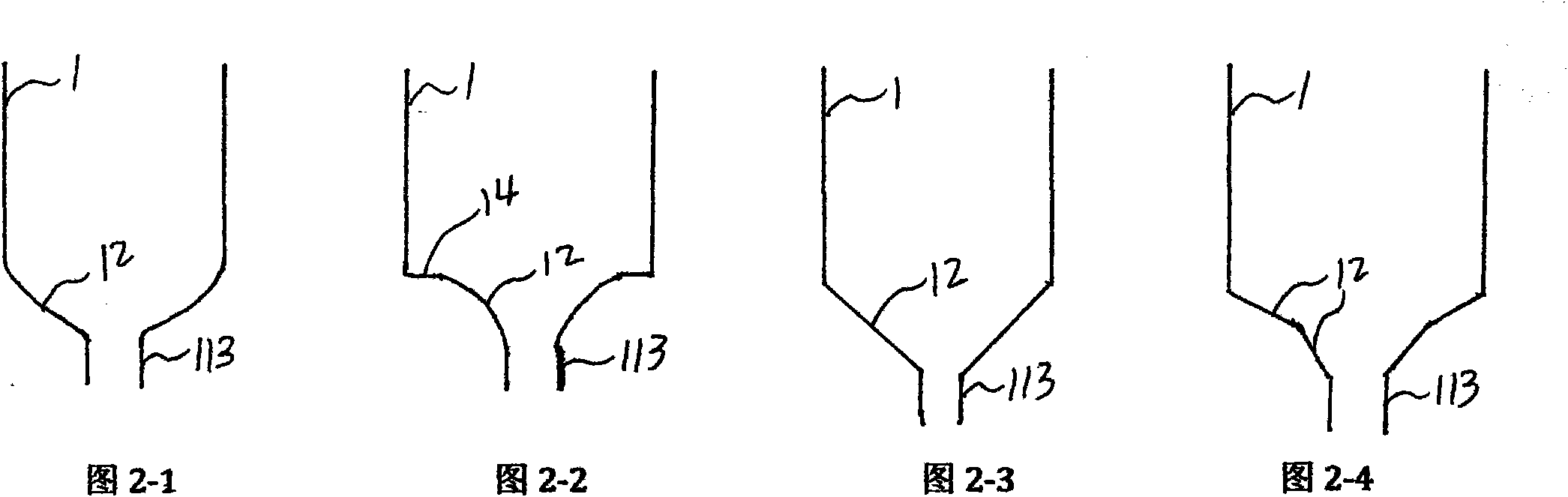

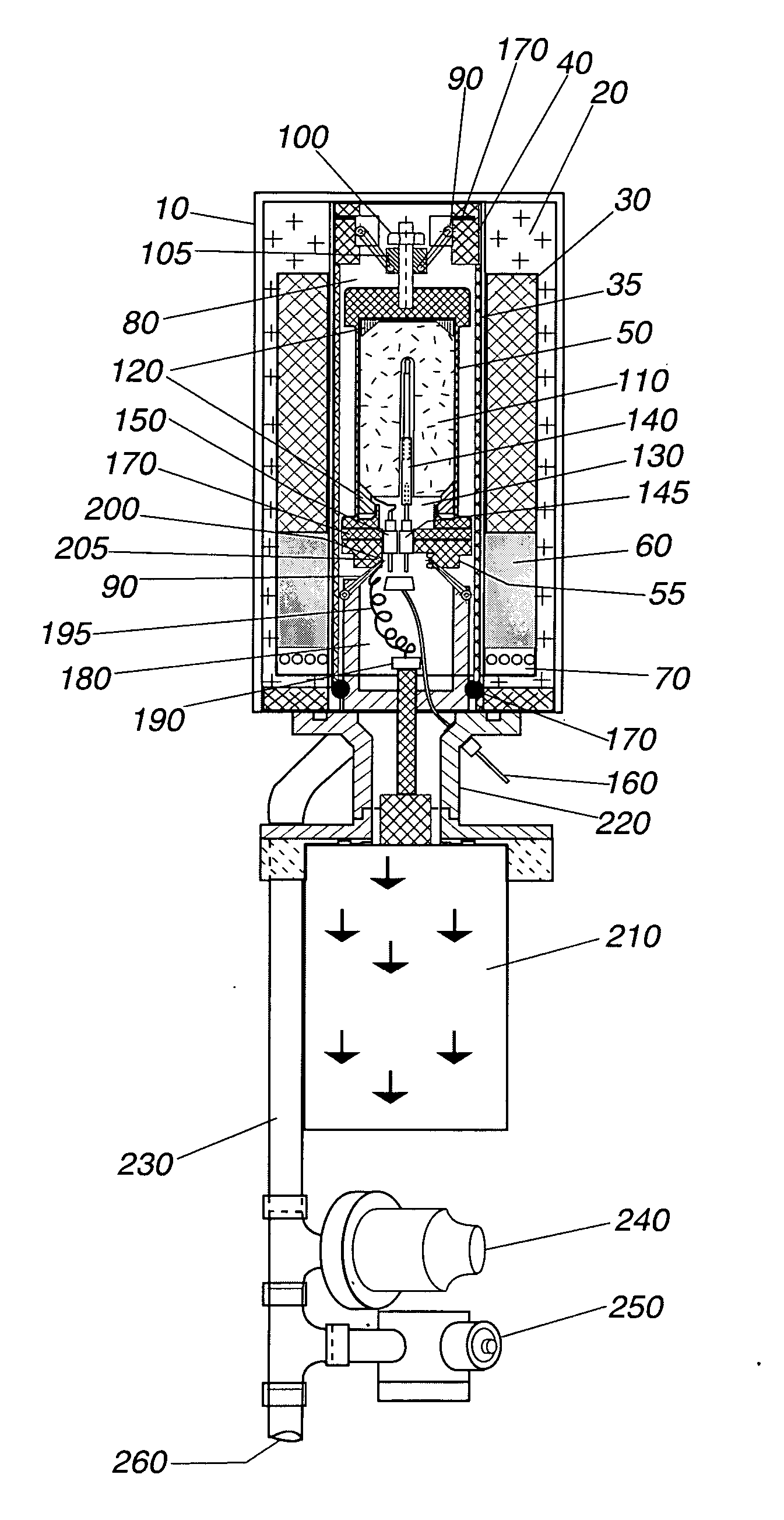

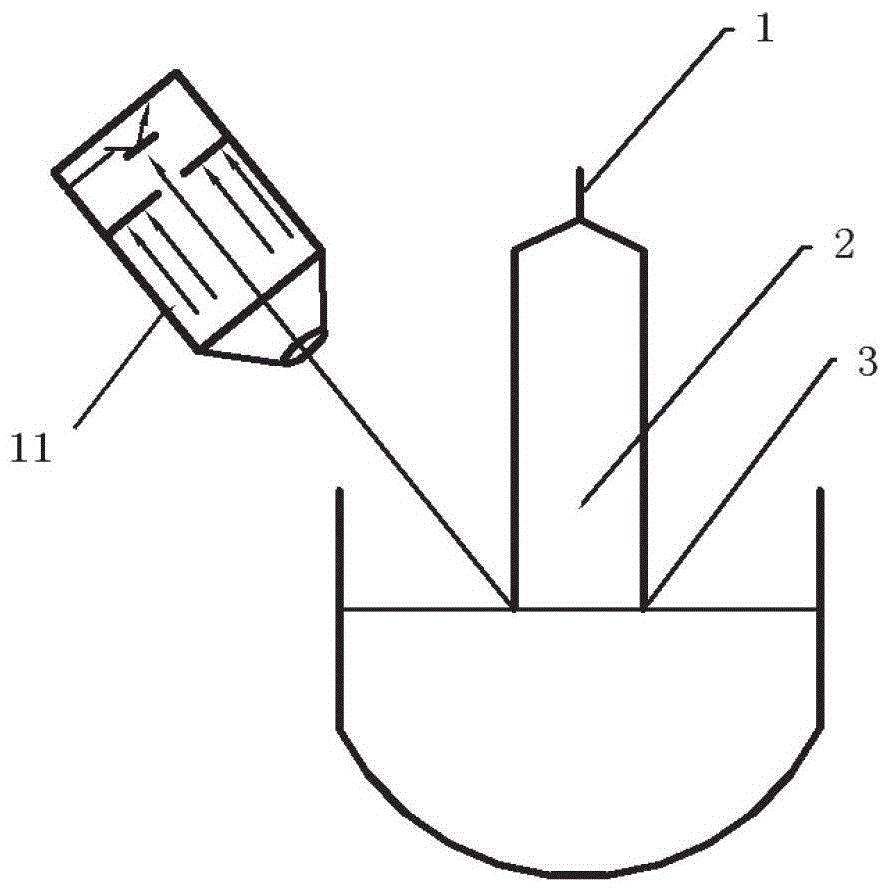

Method and device for growing germanium crystal

ActiveCN101736401APolycrystalline material growthFrom frozen solutionsCrucibleCrystallization temperature

The invention discloses a method and a device for growing a germanium crystal. The method comprises the following steps of: loading a first Ge raw material into a crucible which is provided with a crystal seed mixer with crystal seeds placed therein; loading a second Ge raw material into a loading container which is to be arranged in a quartz ampoule and is used for replenishing the Ge material; sealing the crucible and the loading container in the quartz ampoule; putting the quartz ampoule sealed with the crucible and the loading container into a crystal growing melting furnace provided with a movable ampoule supporting seat which supports the quartz ampoule; melting the first Ge raw material in the crucible to generate a molten mass; melting the second Ge raw material in the container and adding the second Ge raw material into the molten mass; controlling the crystallization temperature gradient of the molten mass so that the molten mass is crystallized when contacting the crystal seeds to form a monocrystalline germanium crystal bar; and cooling the monocrystalline germanium crystal bar. The invention also provides the device which can be used for implementing the method and comprises the loading container, wherein a process for forming the monocrystalline germanium crystal bar includes bluidling 0.3-2.5DEG / cm of temperature gradient in a crystal bar growing zone.

Owner:AXT INC +1

Optical device for directing x-rays having a plurality of optical crystals

ActiveUS20050201517A1Material analysis using wave/particle radiationHandling using diffraction/refraction/reflectionHigh energyX-ray

Devices for improving the capturing and utilization of high-energy electromagnetic radiation, for example, x-rays, gamma rays, and neutrons, for use in physical, medical, and industrial analysis and control applications are disclosed. The devices include optics having a plurality of optical crystals, for example, doubly-curved silicon or germanium crystals, arranged to optimize the capture and redirection of divergent radiation via Bragg diffraction. In one aspect, a plurality of optic crystals having varying atomic diffraction plane orientations are used to capture and focus divergent x-rays upon a target. In another aspect, a two- or three-dimensional matrix of crystals is positioned relative to an x-ray source to capture and focus divergent x-rays in three dimensions.

Owner:X-RAY OPTICAL SYSTEM INC

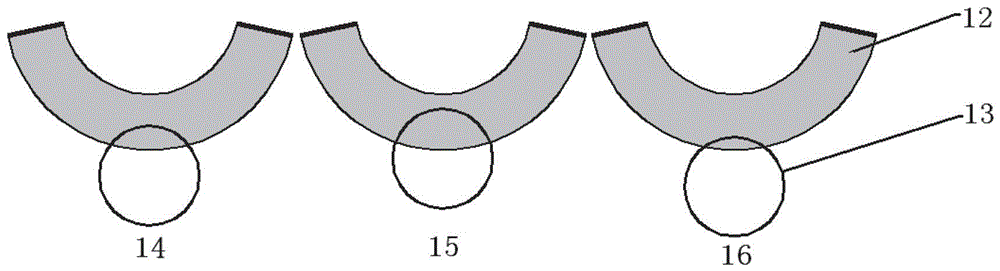

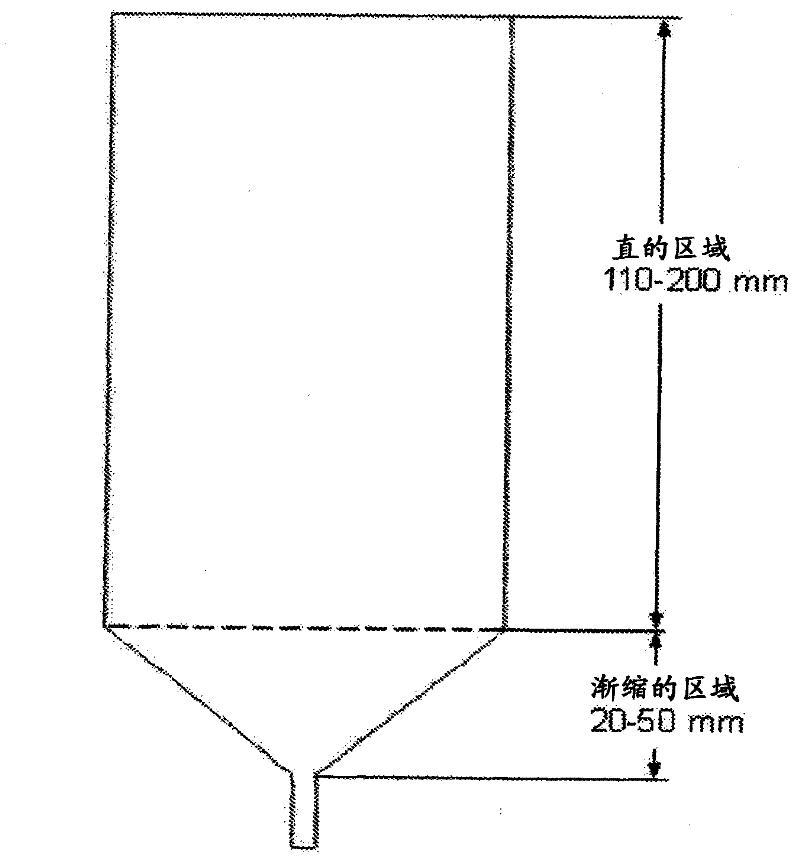

Method and device for casting crystal material by using crystal selector

InactiveCN102312280ALow costImprove photoelectric efficiencyFrom frozen solutionsCrystal orientationSingle crystal

The invention generally relates to a vertical directional solidification casting method using a crystal selection process, which is used for manufacturing a crystal material with a reserved crystal orientation and comprises a polycrystal material and a monocrystal material. When a traditional method for casting the crystal by using the crystal selection process is used for producing the crystal with a bigger size, the problems that the crystal selection effect is bad, a mixed crystal is easy to generate, the internal stress is high, the monocrystal material is hard to obtain or the expected quality requirement is hard to reach and the like exist. The problems are solved by the invention through providing a gradually-changed crystal growth area of which the horizontal cross section is gradually increased, thereby, a good crystal growth effect is obtained, and the obtained cast monocrystal or polycrystal material, such as silicon or silicon germanium, has fewer defects, high quality and a good performance, and is especially suitable for the application of the semiconductor field and the photovoltaic field.

Owner:赵钧永

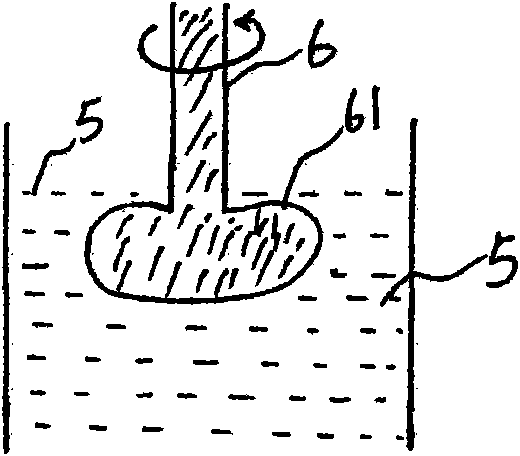

Air-flotation type mechanical polishing method

InactiveCN101422872AImprove and stabilize qualityImprove process pass ratePolishing machinesMetal working apparatusGemstoneOptical glass

The invention discloses a method of air-floating mechanical polishing, mainly adaptable on fine grinding and super-smooth surface processing of metal parts, optical glass, germanium crystal, monocrystalline silicon wafer, gemstone, quartz crystal, etc. The method is technically characterized in that a millstone with even air-jet, which is close to the surface of a rotating workpiece on the chassis, together with the workpiece is immersed in polishing solution with certain abrasive inside; the millstone can rotate in the opposite direction to the workpiece, or can stay still; in the polishing process, a layer of air-liquid membrane is naturally formed between the surfaces of the millstone and the workpiece; while the abrasive in the air-liquid membrane flexibly and evenly polish the workpiece. The invention is proved by practical application that the method fundamentally improves and stabilizes the quality of super-smooth surface mechanical polishing of the workpiece, greatly increases the procedure qualification rate and overcomes the shortcoming of the original polishing process that the operators are required to have high technical capability and rich experience.

Owner:昆明市凯跃机电塑料有限责任公司

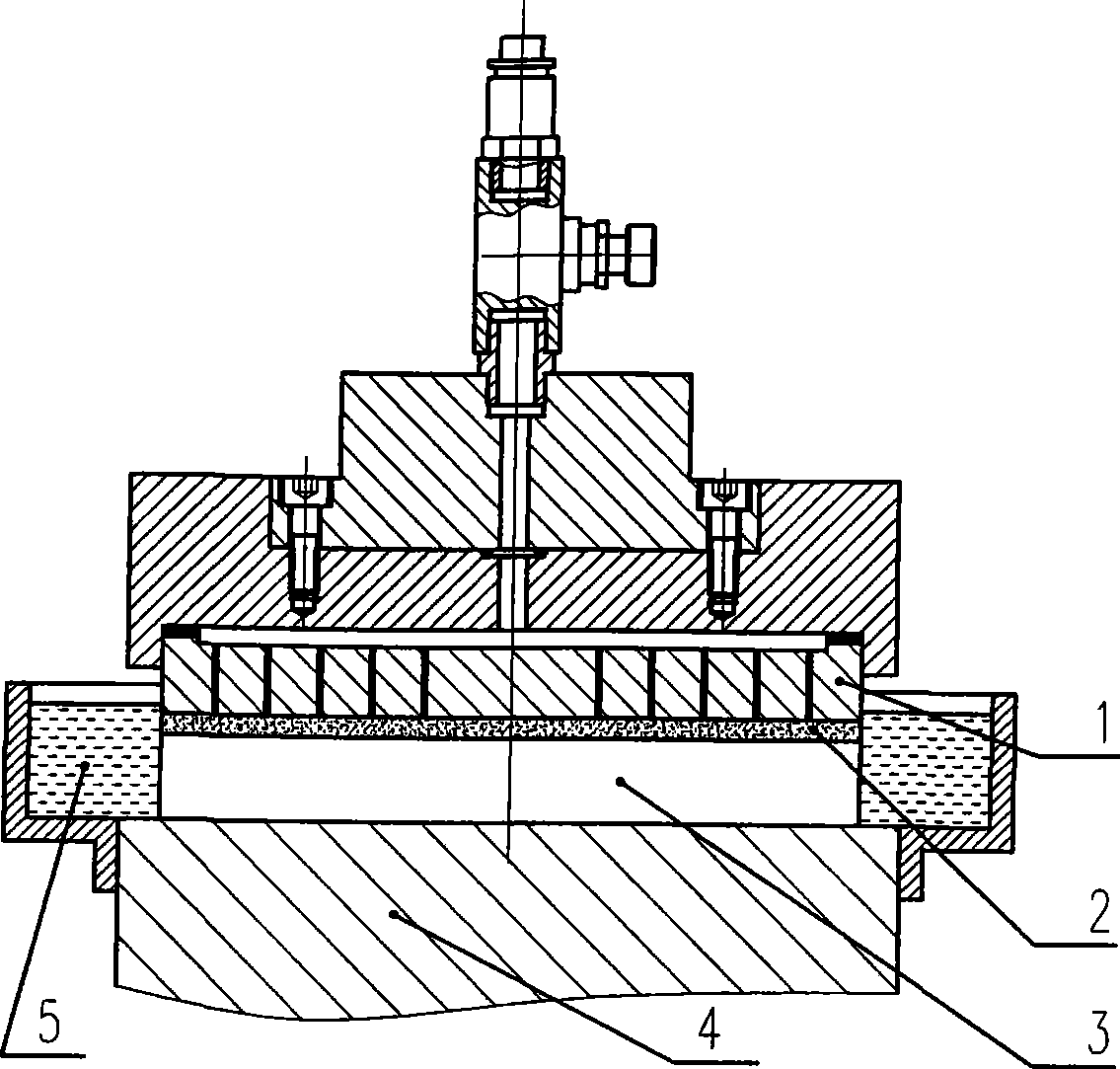

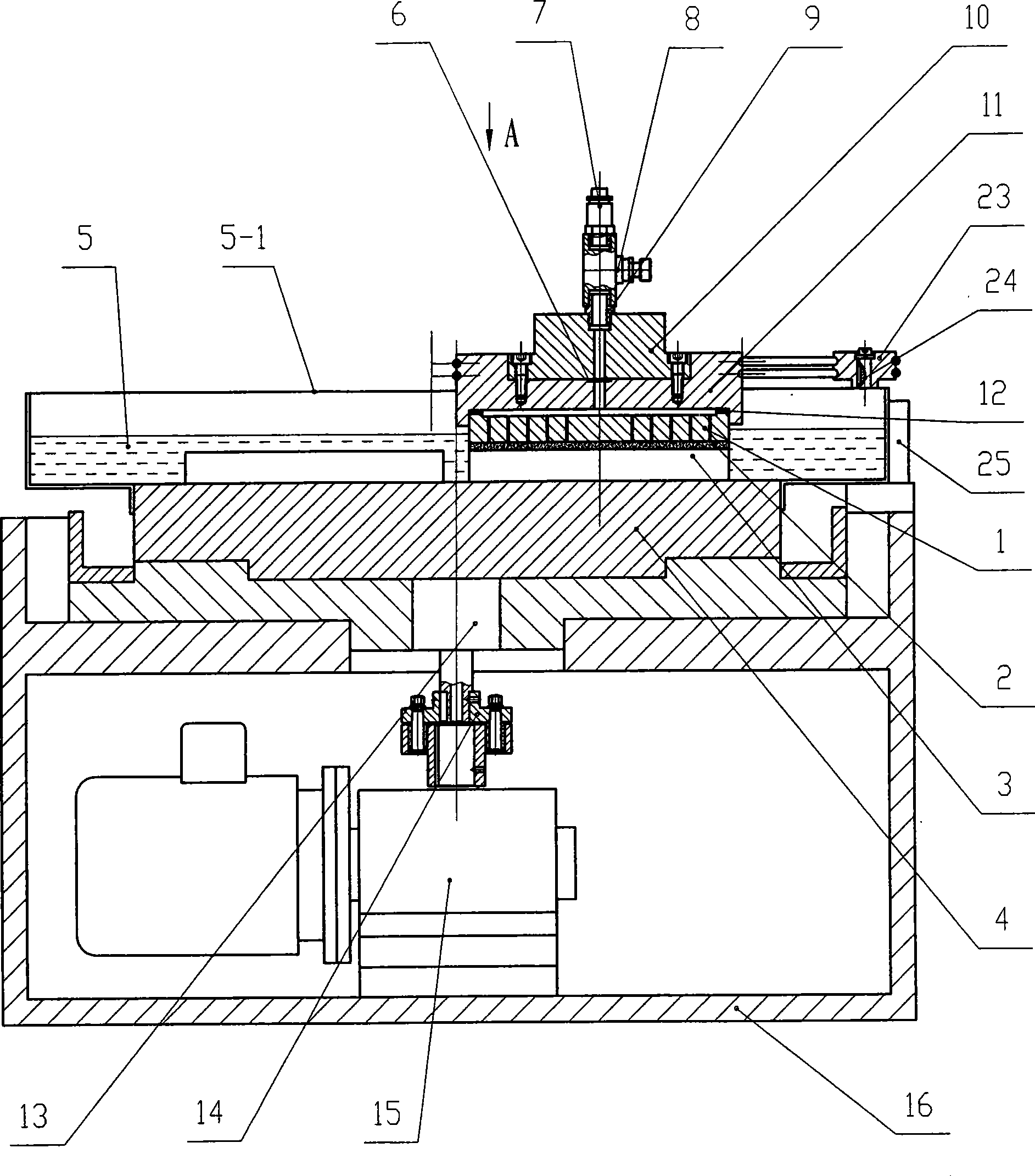

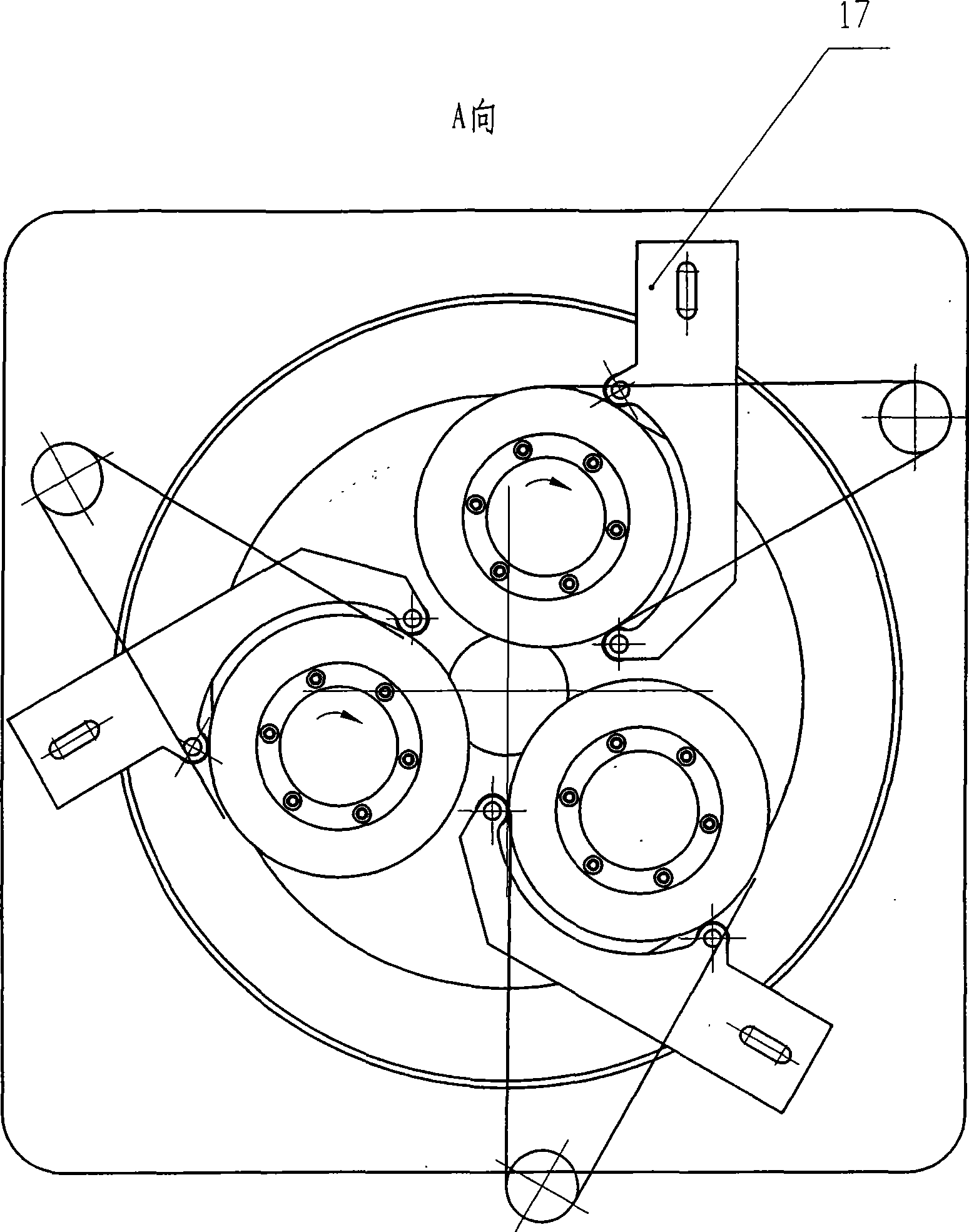

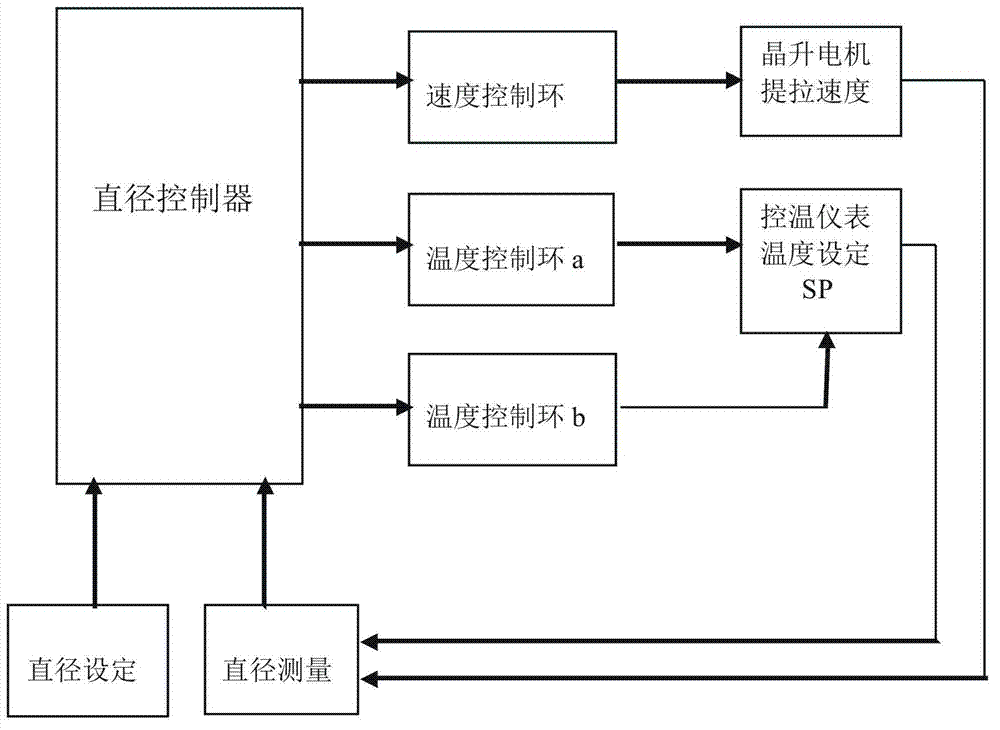

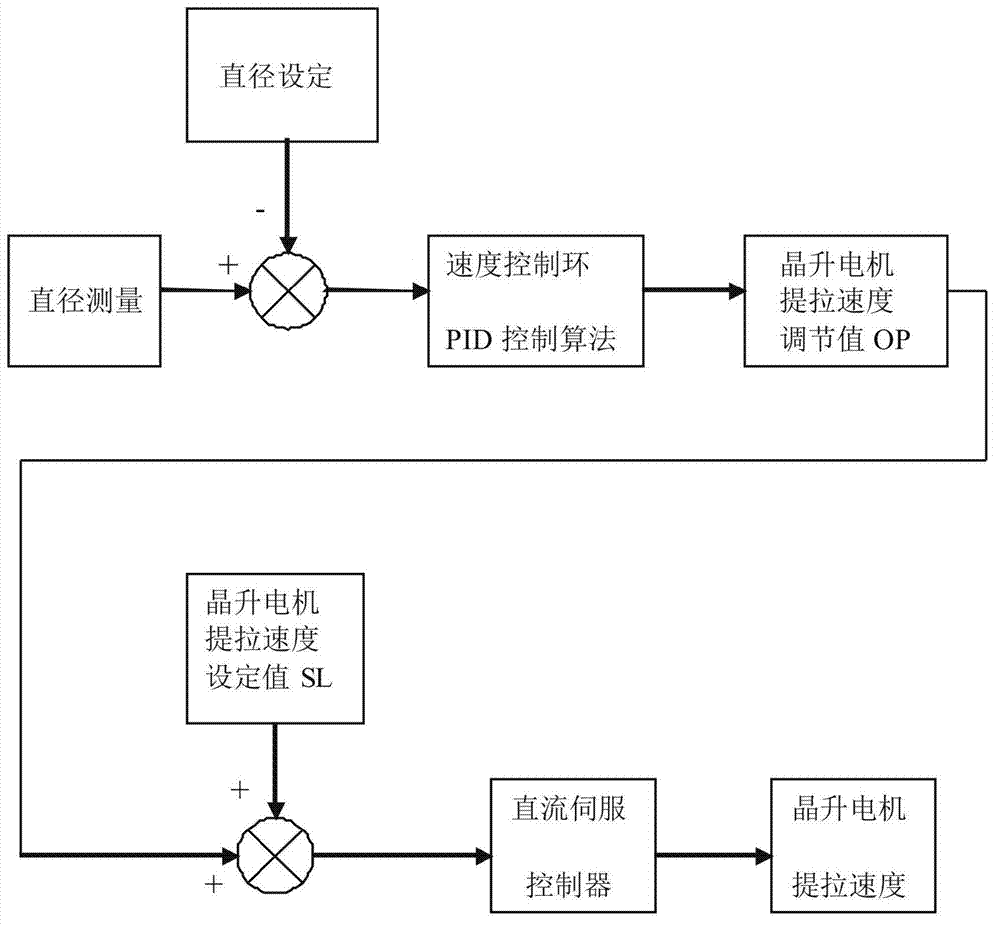

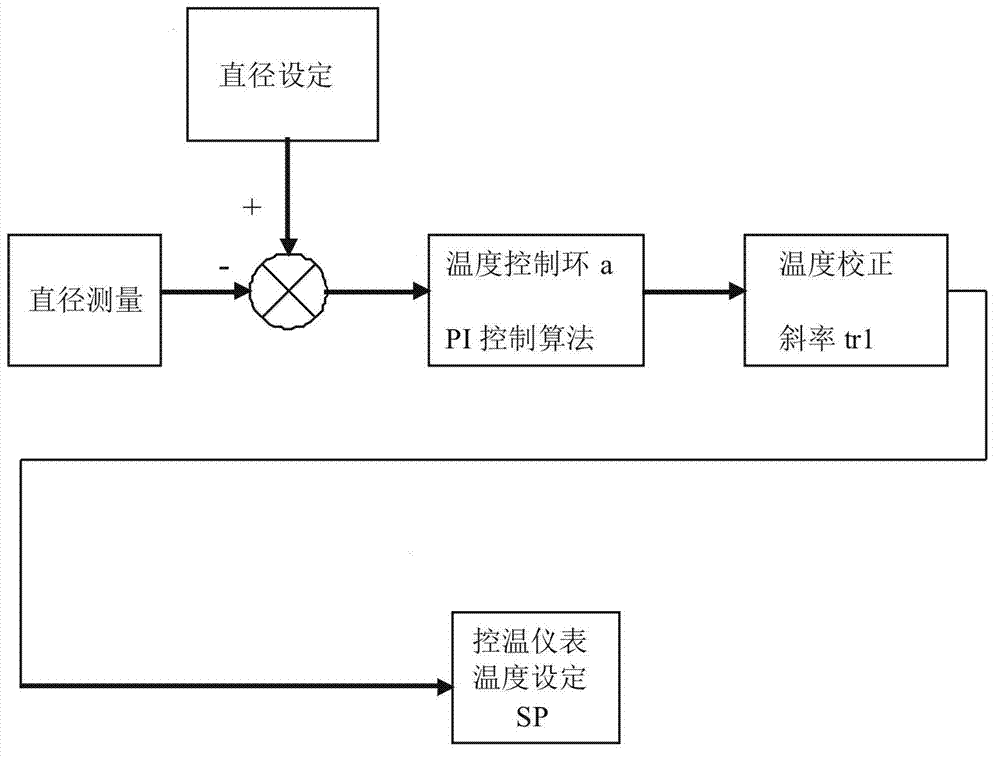

Automatic equal diameter controlling method for germanium single crystal straight-pull growth method

InactiveCN102758250AReduce wasteIncrease productivityBy pulling from meltTemperature controlSingle crystal

The invention discloses an automatic equal diameter controlling method for germanium single crystal straight-pull growth method, which includes the following steps: setting the diameter of the germanium crystal required to be prepared, setting the initial lifting speed SL of a crystal rise motor, and establishing a speed control ring, a temperature control ring a and a temperature control ring b. When a diameter measurement value deviates from a diameter set value during the growth process of the germanium single crystal, a diameter deviation e1 is formed between the diameter measurement value and the diameter set value, then the three control rings are matched mutually to automatically adjust lifting speed of the crystal rise motor and the temperature set SP of a temperature controller, so as to enable the diameter measurement value to be equal to the diameter set value. The automatic equal diameter controlling method improves the manual diameter control during the germanium single crystal production into automatic diameter control, improves the production efficiency, reduces the wastes caused by the follow-up polishing, rounding and slicing processes of the single crystal bar.

Owner:XAUT CRYSTAL GROWING TECH CO LTD

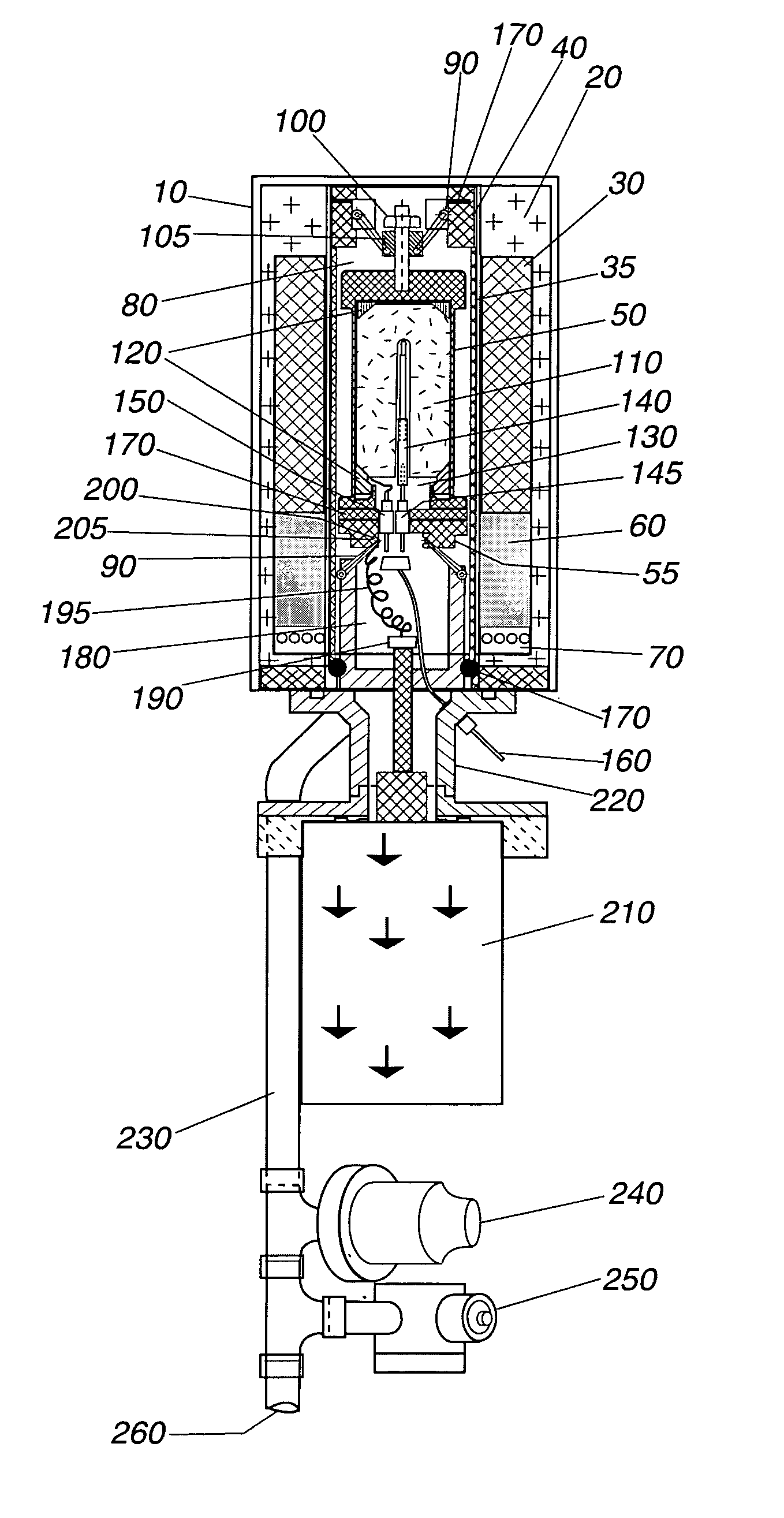

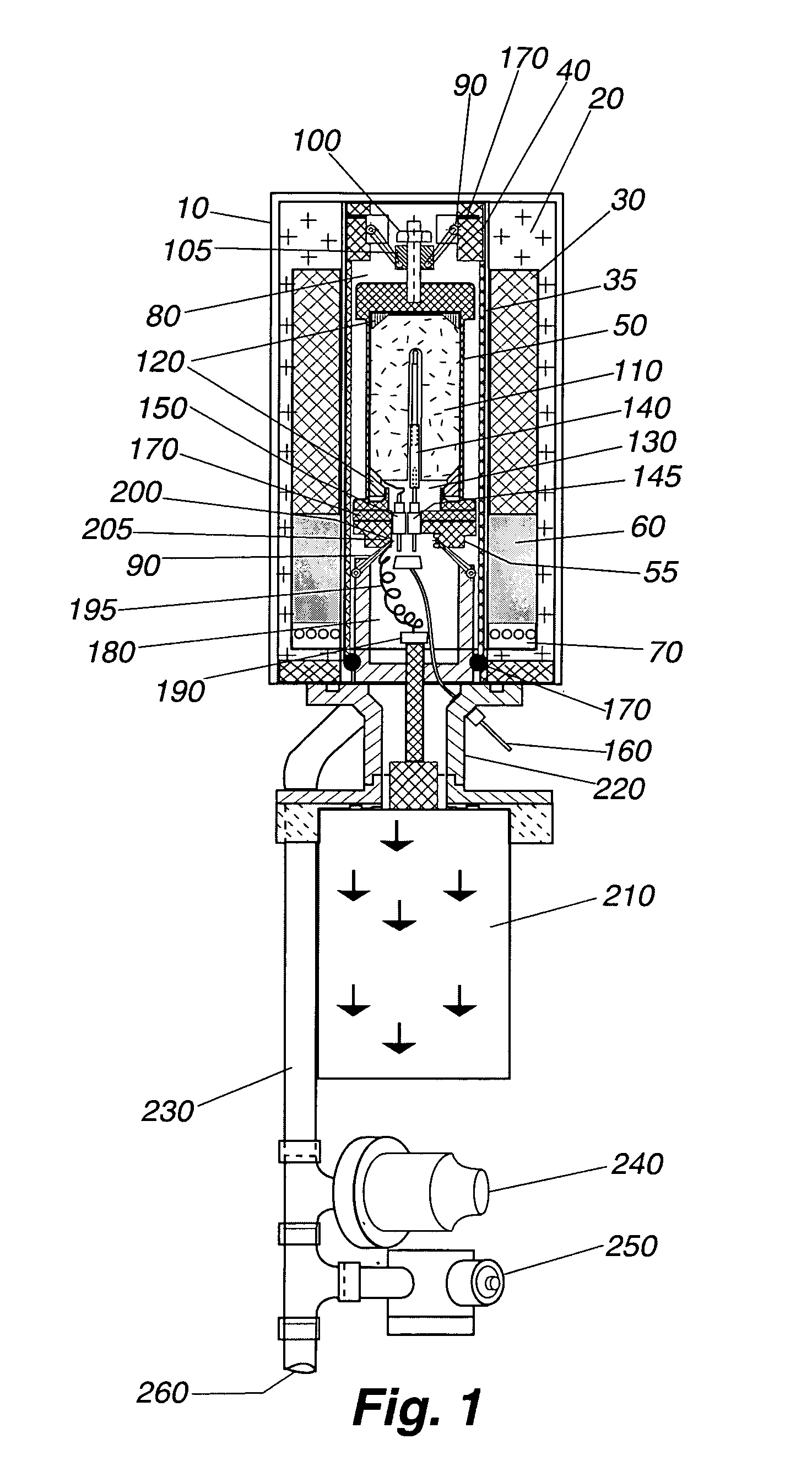

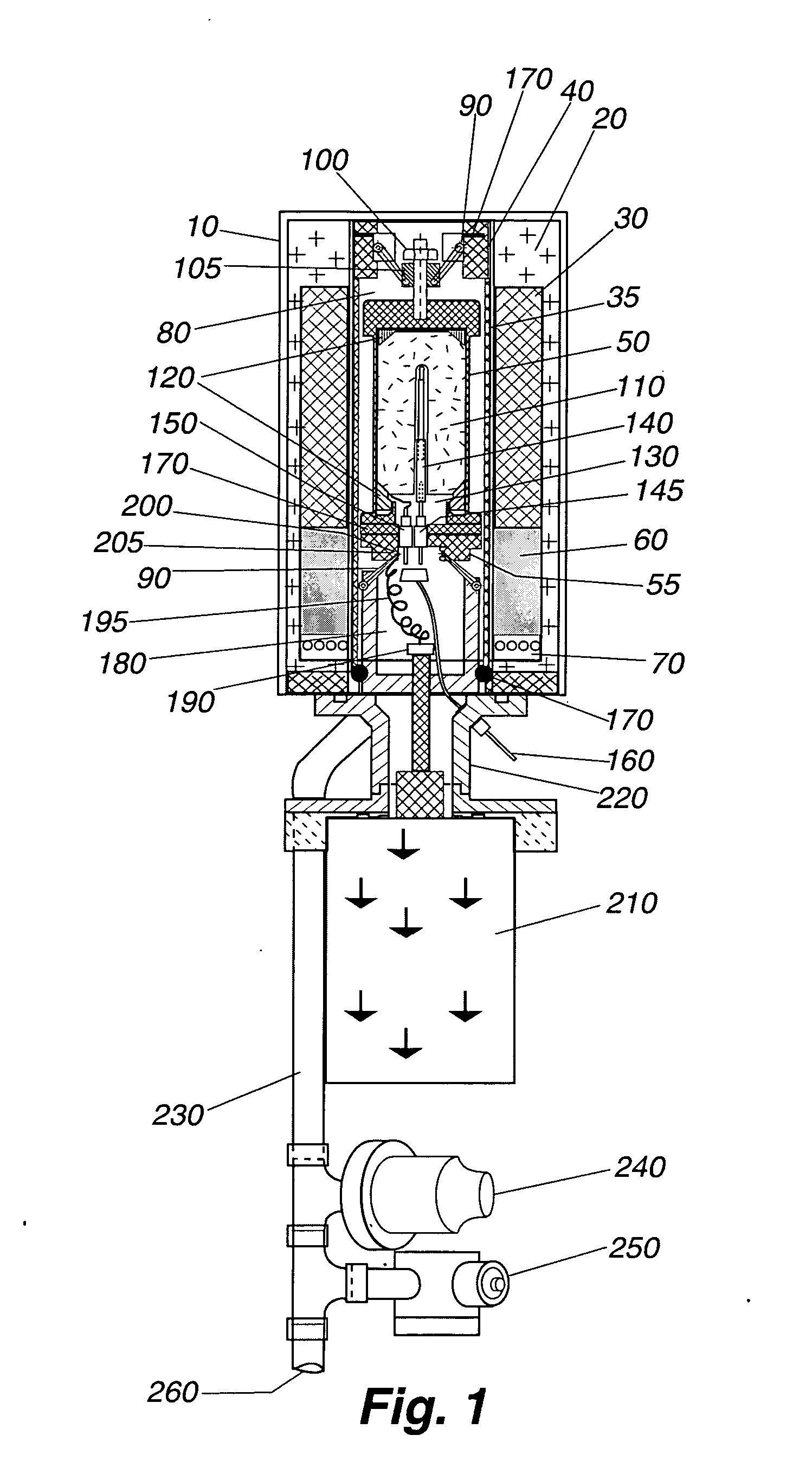

Handheld isotope identification system

InactiveUS7161150B2Radiation pyrometryMaterial analysis using wave/particle radiationNitrogenIsotope

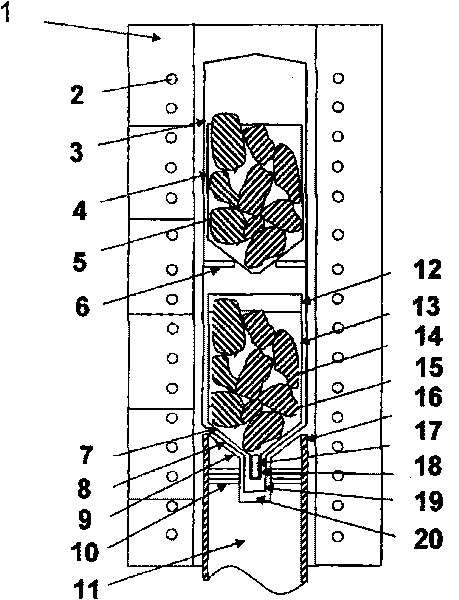

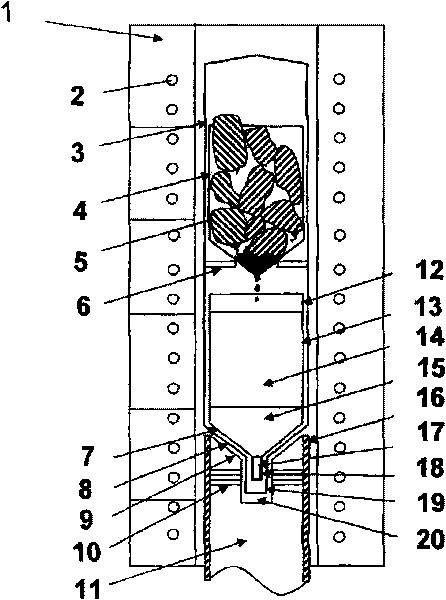

A portable radiation detector using a high-purity germanium crystal as the sensing device. The crystal is fabricated such that it exhibits a length to width ratio greater than 1:1 and is oriented within the detector to receive radiation along the width of said crystal. The crystal is located within a container pressurized with ultra-pure nitrogen, and the container is located within a cryostat under vacuum.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

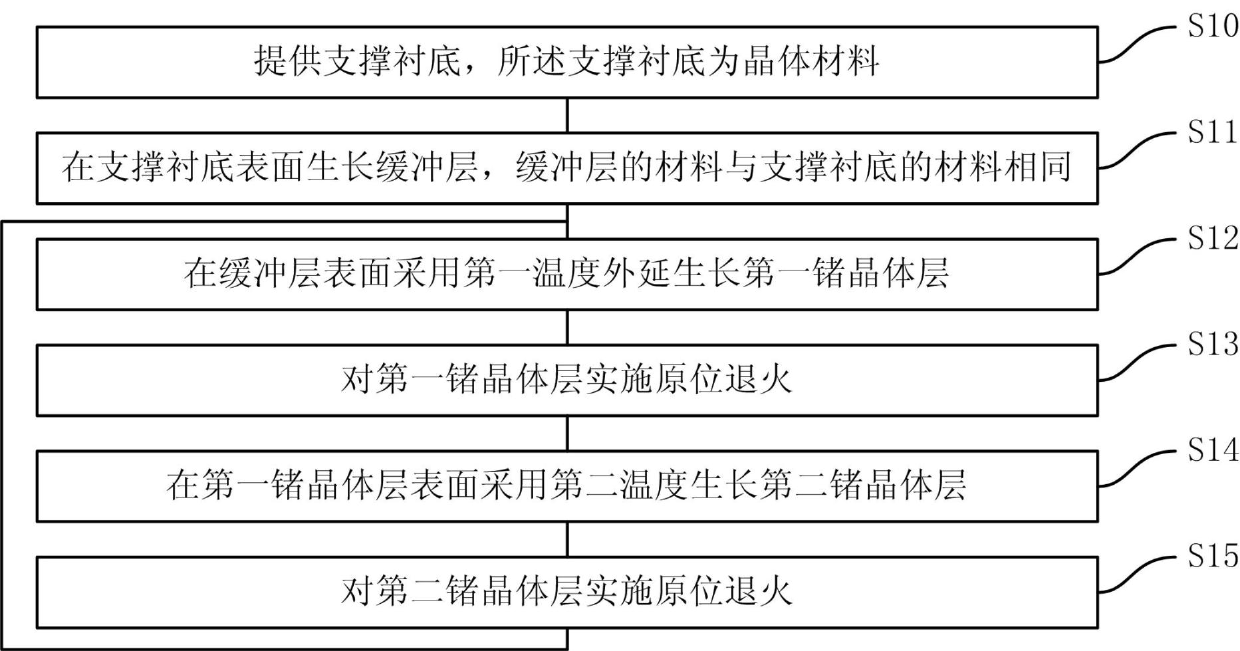

Growth method of germanium substrate and germanium substrate

ActiveCN102383192AImprove crystal qualityFast growthPolycrystalline material growthFrom chemically reactive gasesSingle crystalOptoelectronics

The invention provides a growth method of a germanium substrate. The growth method comprises the following steps of: providing a supporting substrate, wherein the supporting substrate is a crystal material; epitaxially growing a first germanium crystal layer on the surface of the supporting substrate at a first temperature; and epitaxially growing a second germanium crystal layer on the surface of the first germanium crystal layer at a second temperature, wherein the first temperature is lower than the second temperature. The growth method has the advantages that: a growth process combining low and high-temperature germanium epitaxial growth is provided; firstly, a germanium layer is grown at a low temperature, thus the germanium layer has low epitaxial growth speed, has two-dimensional growth characteristics and is completely relaxed, and the thin low-temperature germanium layer has multiple defects and is easy for stress relaxing and dislocation annihilation; and then, a germanium epitaxial layer is grown at a high temperature, thus the germanium layer has high growth speed, and a single crystal germanium layer which has high crystal quality and is completely relaxed can be obtained.

Owner:SHANGHAI SIMGUI TECH +1

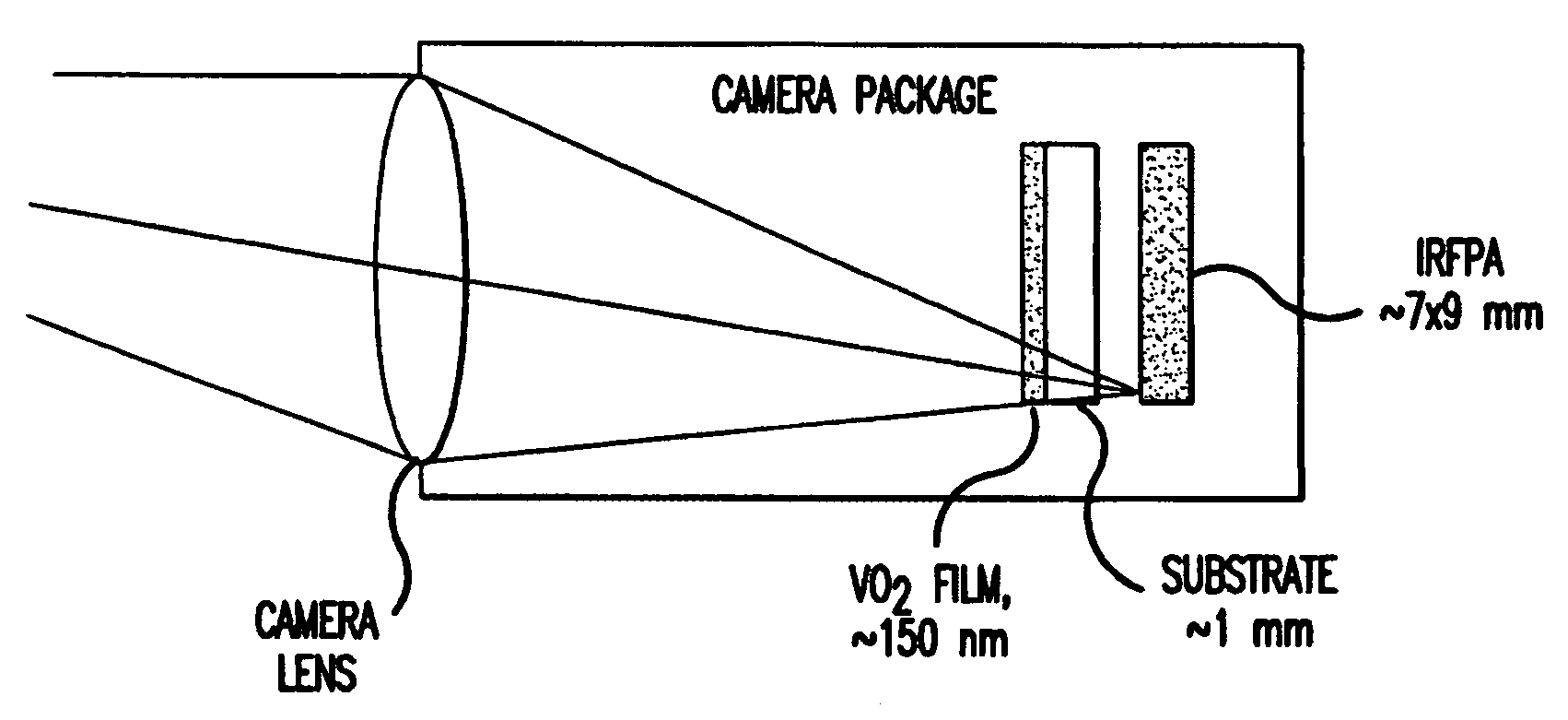

Passive broadband long wave and mid-wave infrared optical limiter device

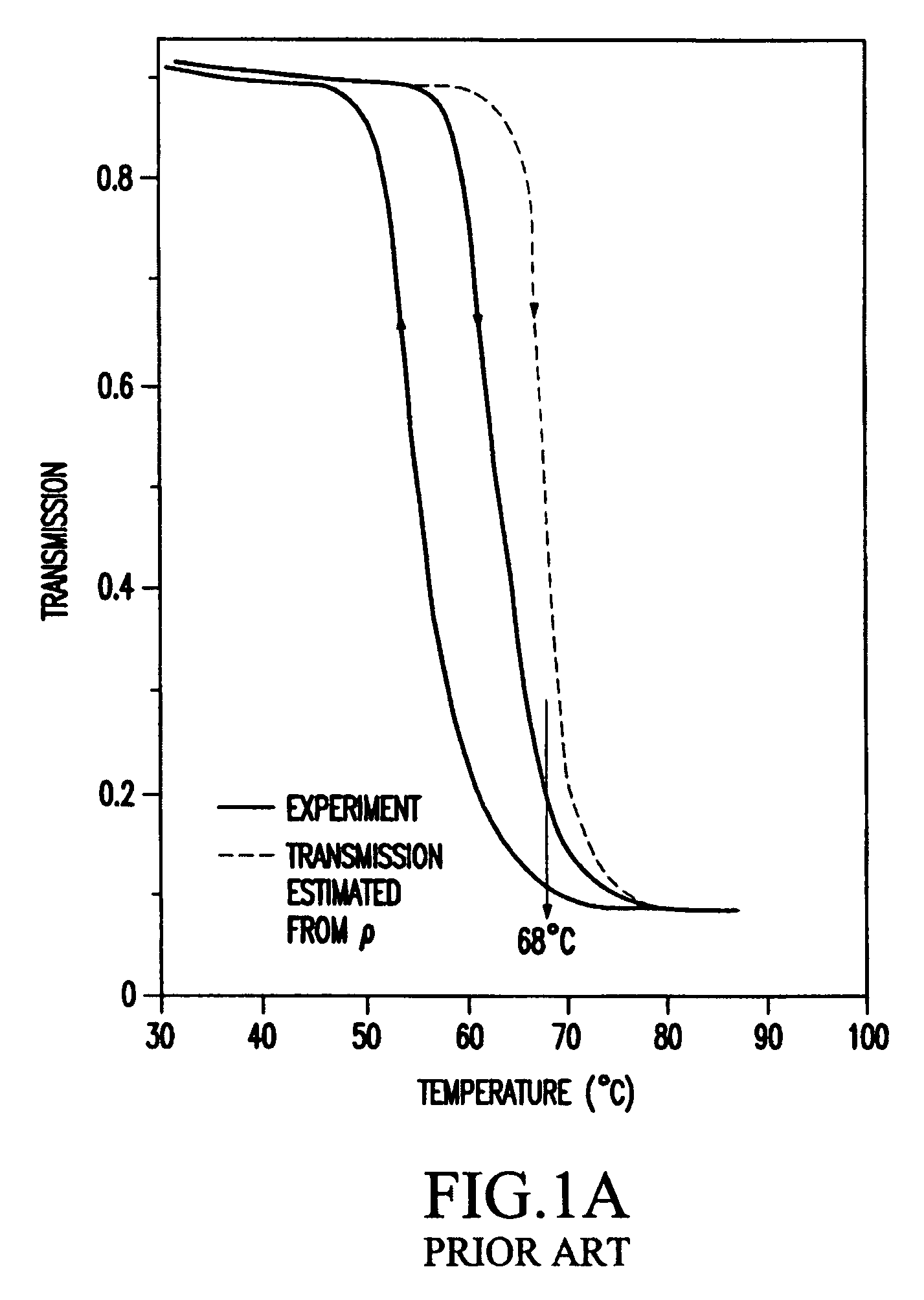

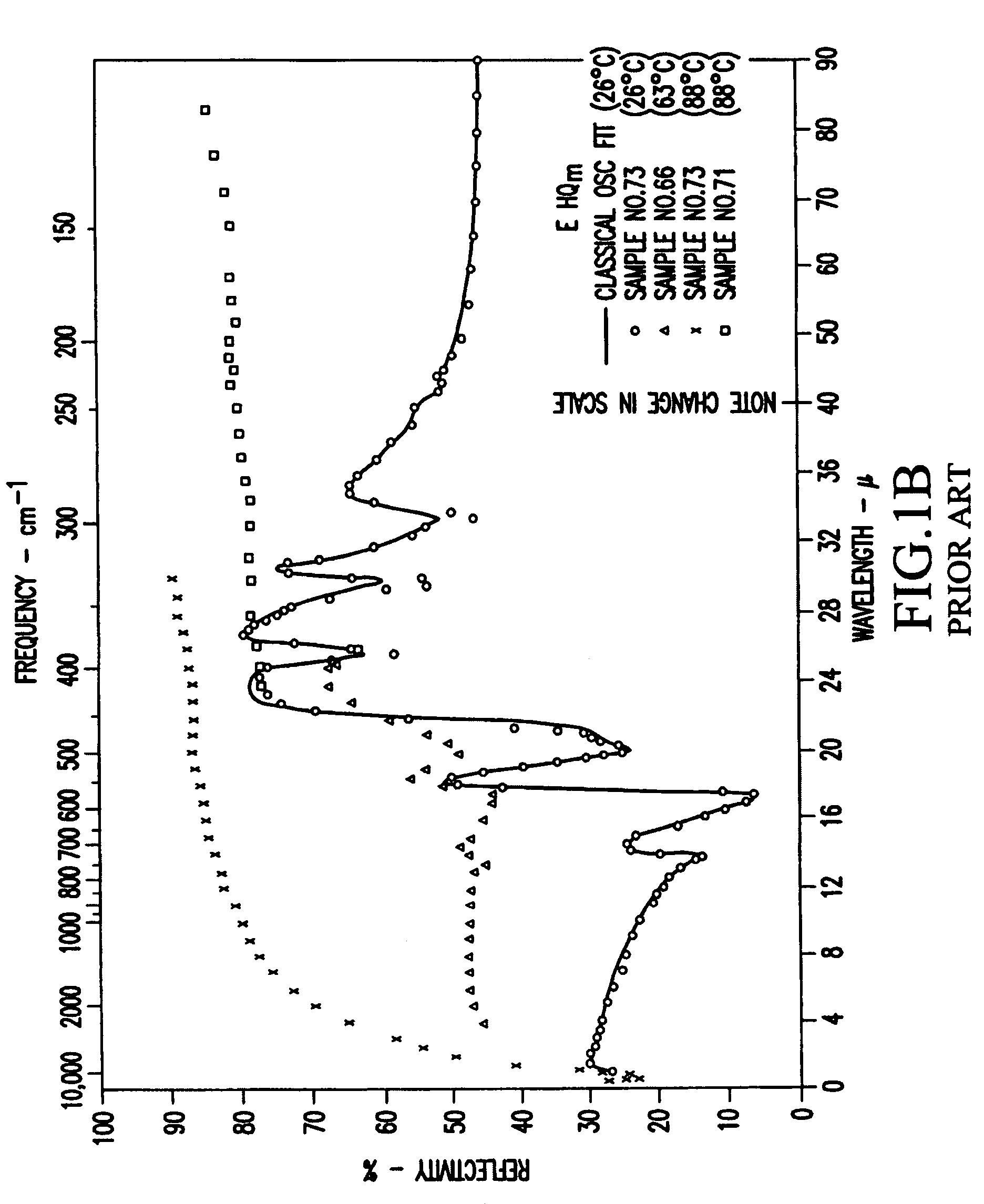

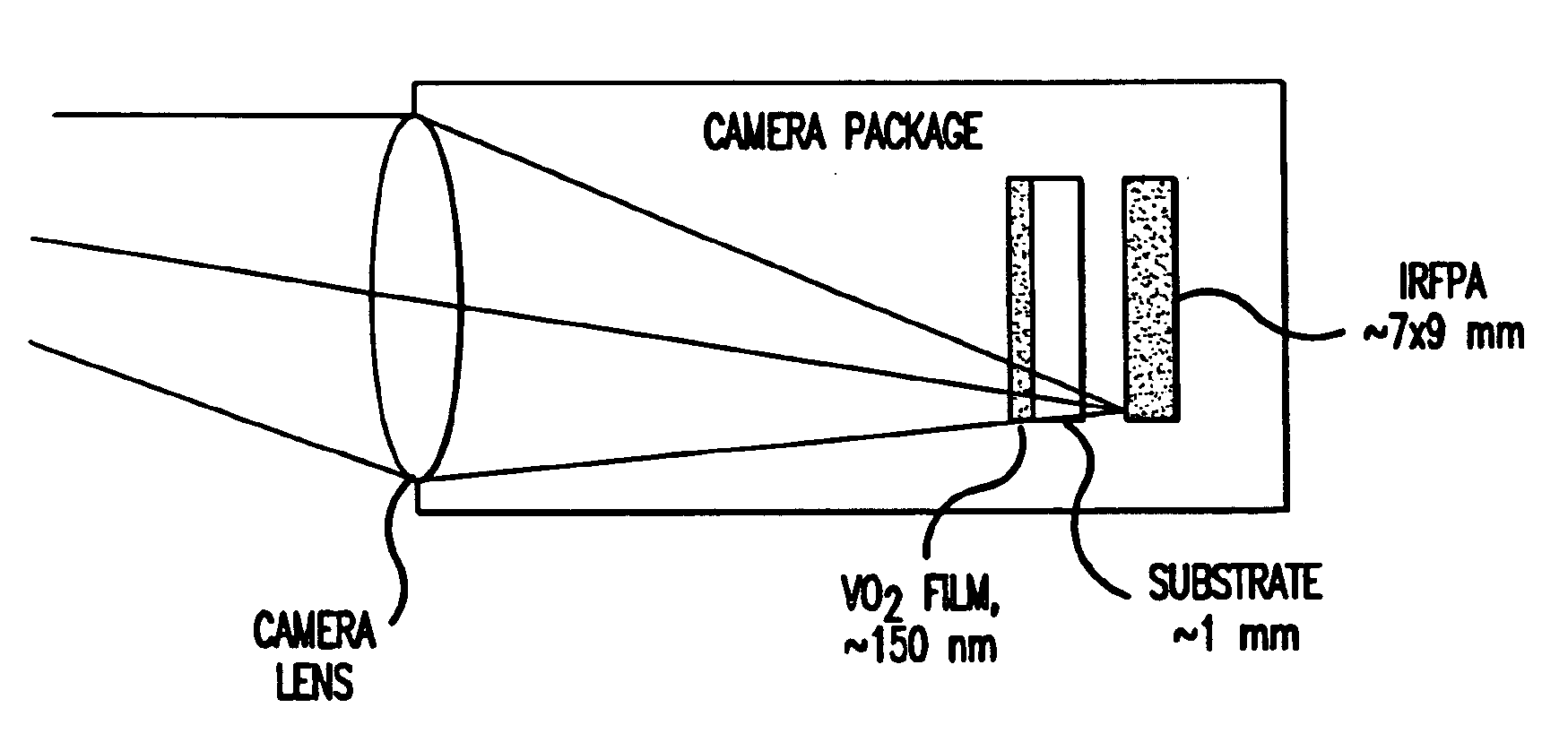

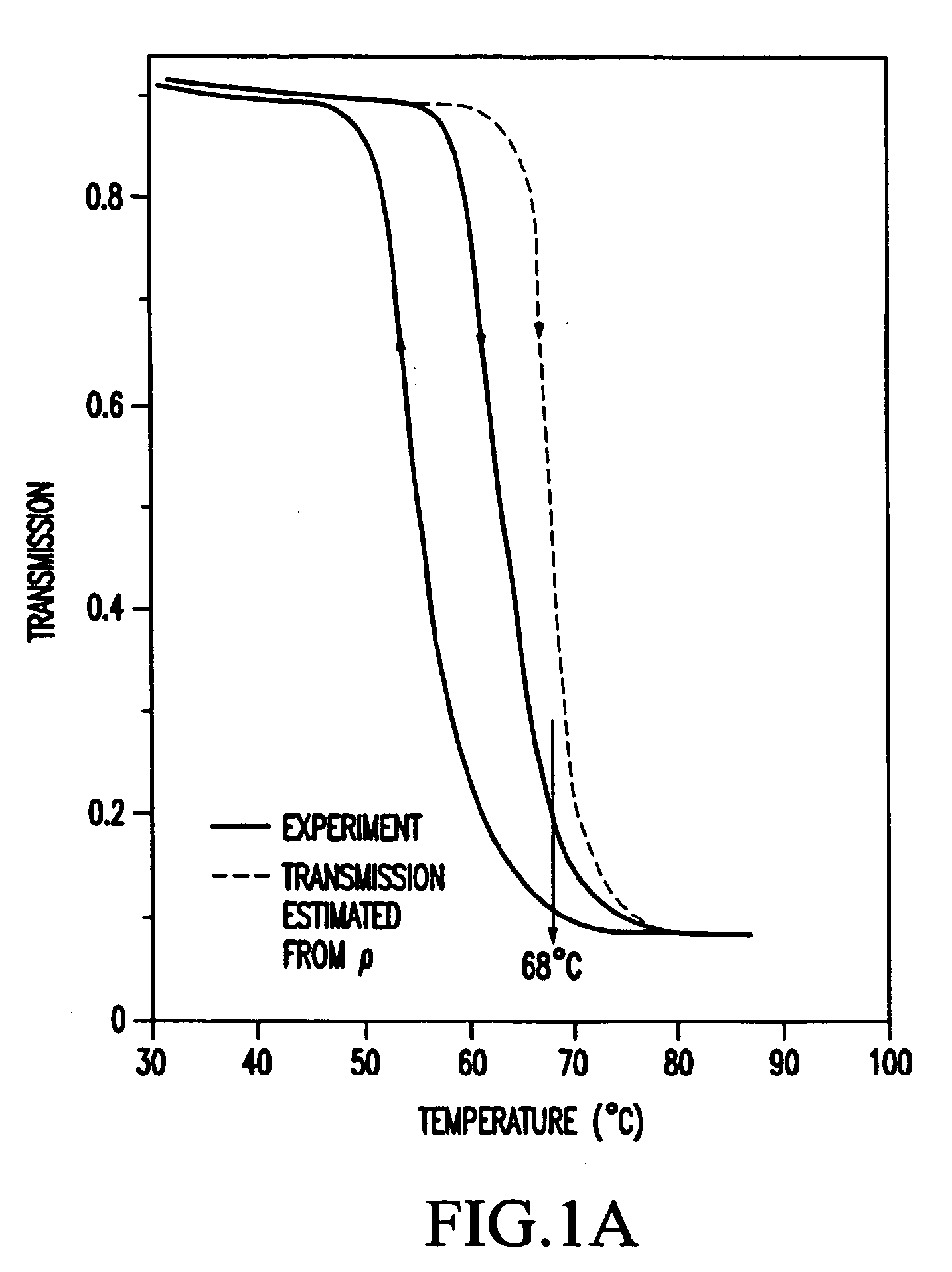

InactiveUS7494232B2Avoid collisionLimited amountTelevision system detailsMirrorsVanadium dioxideSesquioxide

Owner:LOCKHEED MARTIN CORP

Alloy germanium chinlon filament and production method thereof

InactiveCN101665987APromote circulationImprove deodorization abilityElectroconductive/antistatic filament manufactureMelt spinning methodsAlloyTitanium

The invention provides an alloy germanium chinlon filament and a production method thereof. The alloy germanium chinlon filament comprises the following components in percentage by weight: 2-6 percentof nano alloy germanium and 94-98 percent of chinlon 6 slice. The nano alloy germanium comprises a germanium crystal and a titanium crystal, wherein the weight ratio of the germanium crystal and thetitanium crystal is 3:1. Compared with the common chinlon filament fabric, the fabric made of the alloy germanium chinlon filament has the following technical advantages: far infrared ray function: the fabric can keep warm and promote blood circulation; (2) antistatic ability; (3) deodorization: nano alloy germanium is provided with large holes, has higher deodorizing ability and can repeatedly adsorb and decompose odor; (4) good air permeability, refreshing and comfort.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

Passive broadband long wave and mid-wave infrared optical limiter device

InactiveUS20060132906A1Avoid collisionLimited amountTelevision system detailsPhotometry using reference valueVanadium dioxideSesquioxide

Method for limiting amount of radiation impinging on a radiation-sensitive detector device by directing radiation toward the detector, permitting the radiation to impinge upon the detector device when the radiation is below a predetermined threshold, and utilizing radiation having wavelengths different from signals of interest to initiate limiting of the radiation impinging upon the detector when the predetermined threshold is exceeded. The optical limiter includes an IR limiting layer pair selected so that energy from visible and near infrared radiation activates the optical limiter. The limiting layer pair may includes a layer closer to the source of radiation of e.g. vanadium dioxide, vanadium sesquioxide, or germanium crystal and a layer further from the source of radiation of e.g. chalcogenide glass, germanium crystal, or sodium chloride crystal.

Owner:LOCKHEED MARTIN CORP

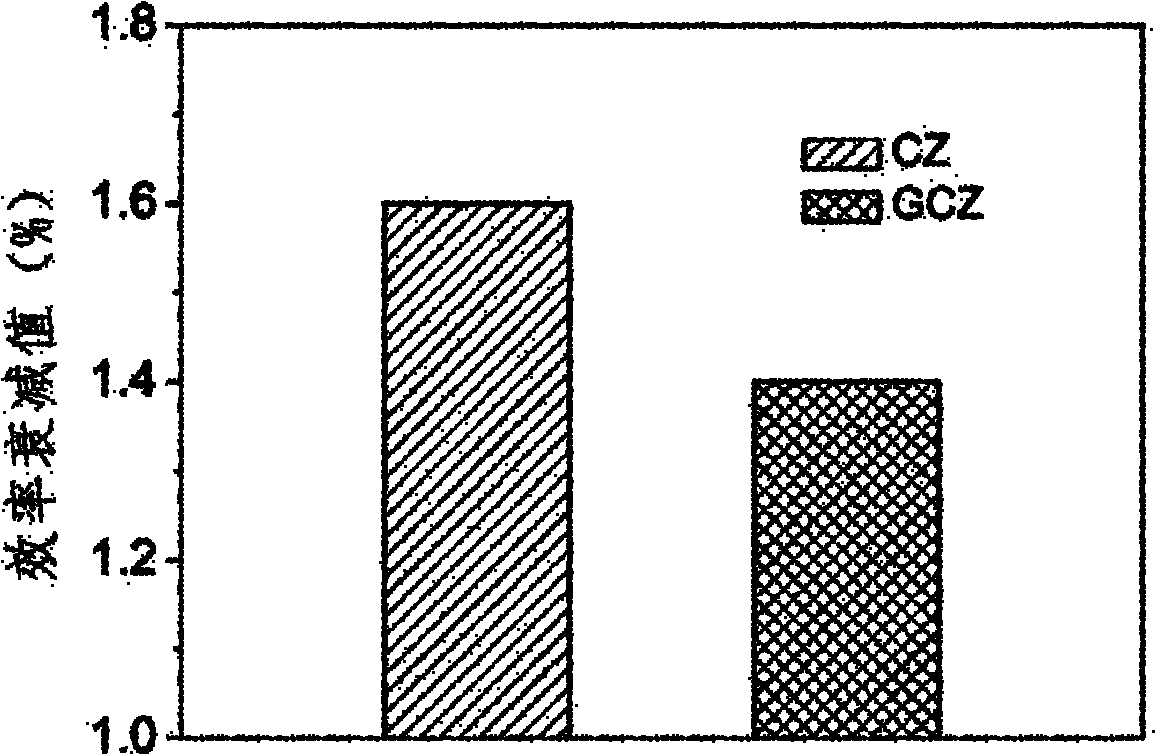

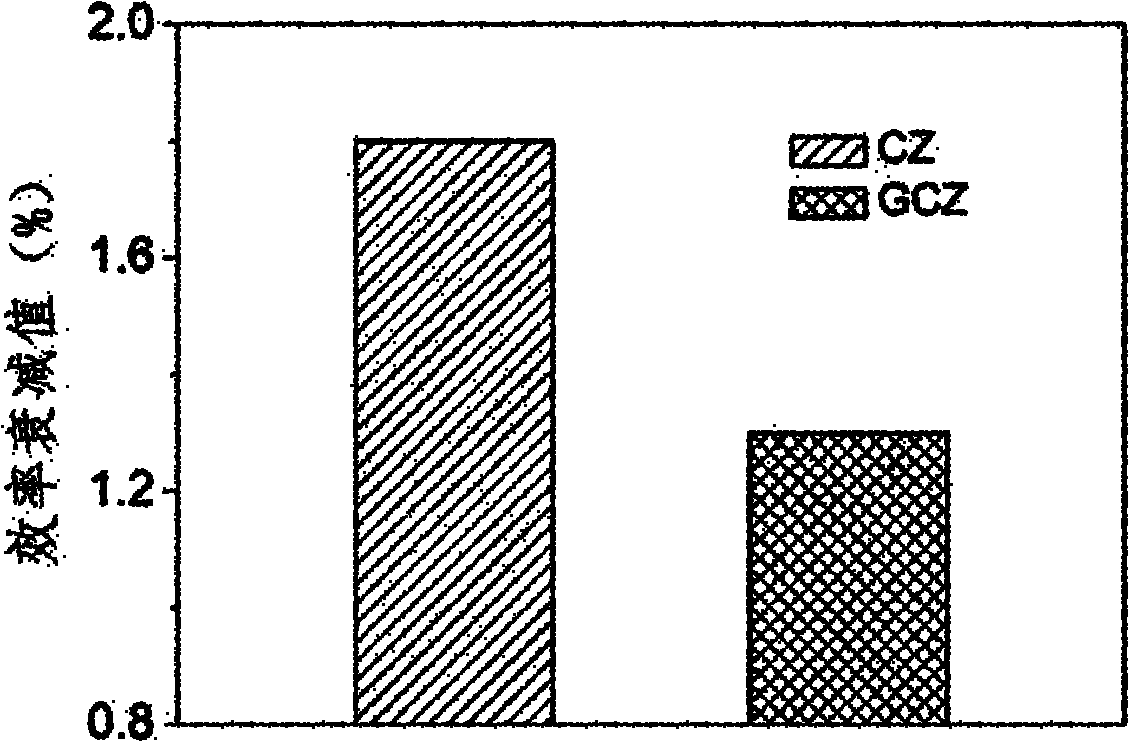

Germanium-doped crystalline silicon solar cell capable of suppressing light attenuation and preparation thereof

ActiveCN102005506AImprove compatibilitySuppress light attenuationFinal product manufacturePhotovoltaic energy generationBoronCrystalline silicon

The invention discloses a germanium-doped crystalline silicon solar cell capable of suppressing light attenuation and preparation thereof. The preparation method comprises the following steps of: doping germanium and boron into a polycrystalline silicon raw material, wherein the concentration of the germanium is 1,018-1,021cm<-3>, and the concentration of the boron is 1,015-1,017cm<-3>; growing germanium-doped crystalline silicon under a protection atmosphere; and slicing the obtained crystalline silicon for the preparation of the solar cell, wherein the preparation of the solar cell comprises the flows of: carrying out cleaning and wool making on an obtained silicon wafer; carrying out phosphorous diffusion after wool making; etching and depositing an anti-reflecting film; and finally, preparing an electrode and sintering to obtain the germanium-doped crystalline silicon solar cell. The invention has the advantages of simple method and low cost, realizes the compatibility of the whole solar cell preparation and conventional processes and prepares the germanium-doped crystalline silicon solar cell capable of suppressing light attenuation.

Owner:ZHEJIANG UNIV

Systems, methods and substrates for single crystal germanium crystal growth

Systems, methods, and substrates for growth of single crystal germanium (Ge) are disclosed. In an exemplary embodiment, a method of growing a single crystal germanium (Ge) crystal is provided. Additionally, the method may comprise charging the first Ge feedstock into a crucible, charging the second Ge feedstock into a container for replenishing the Ge melt material, sealing the crucible and container within the ampoule, Putting the ampoule with the crucible into a crystal growth furnace, and melting the first Ge raw material and the second Ge raw material, and controlling the crystallization temperature gradient of the melt to reproducibly provide single crystal germanium crystals with improved / desired properties ingot.

Owner:AXT INC +1

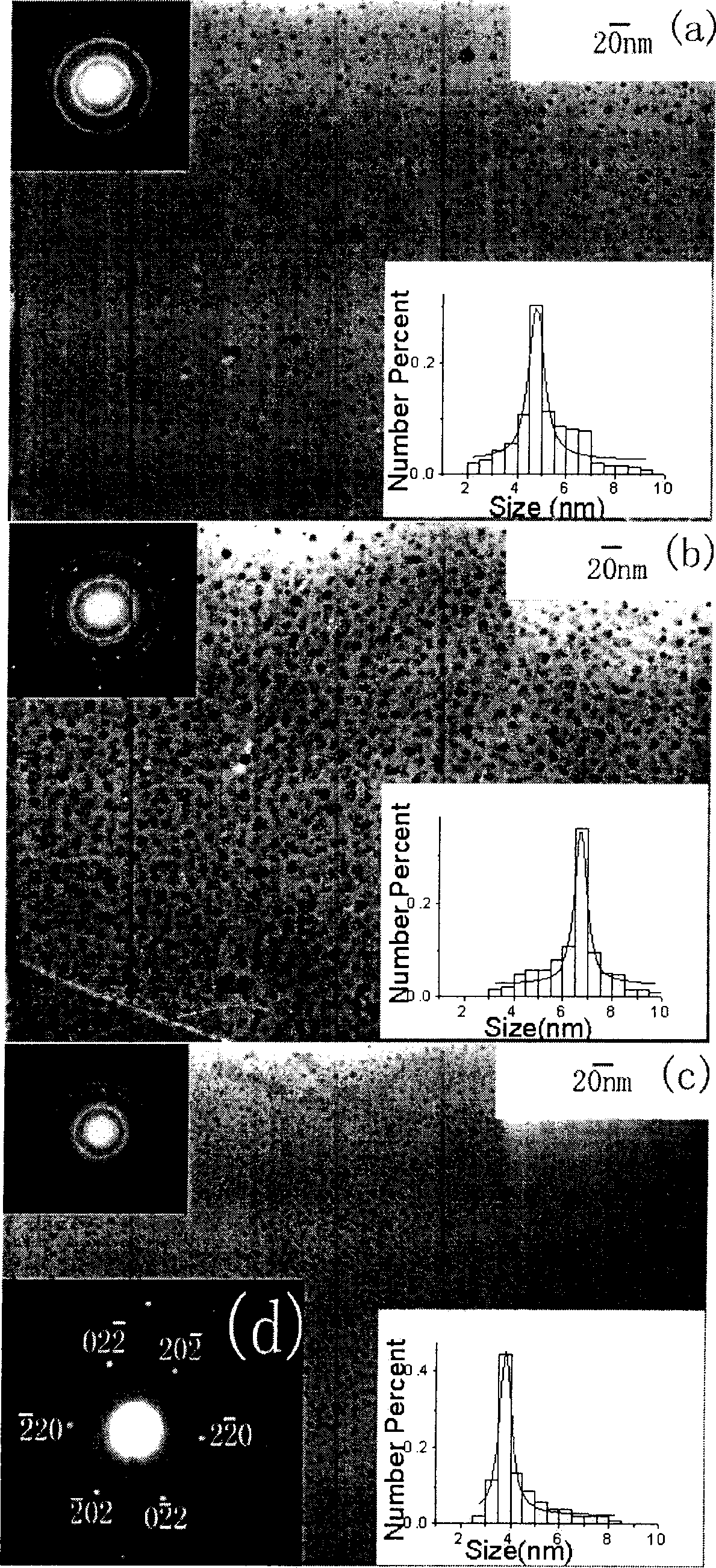

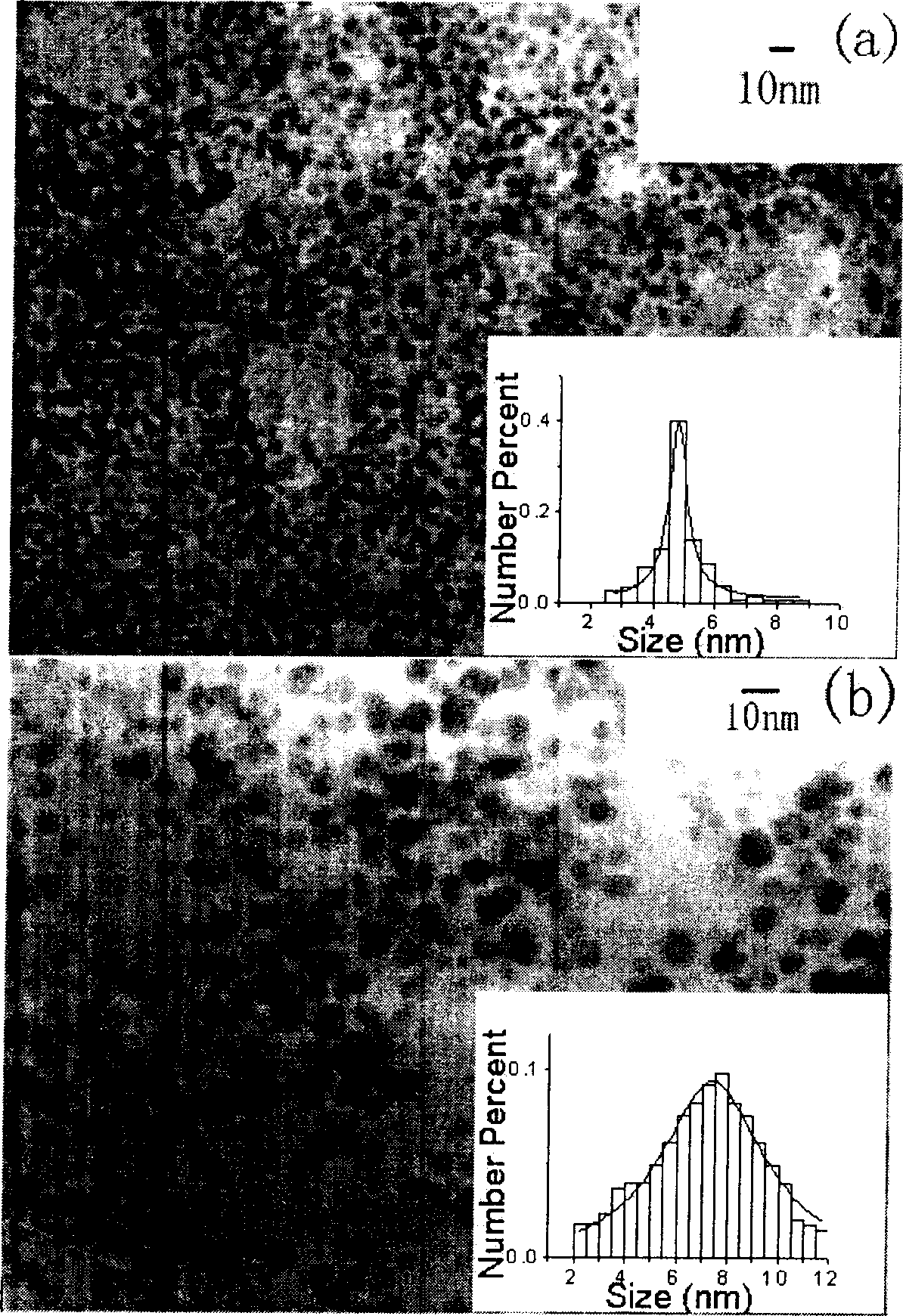

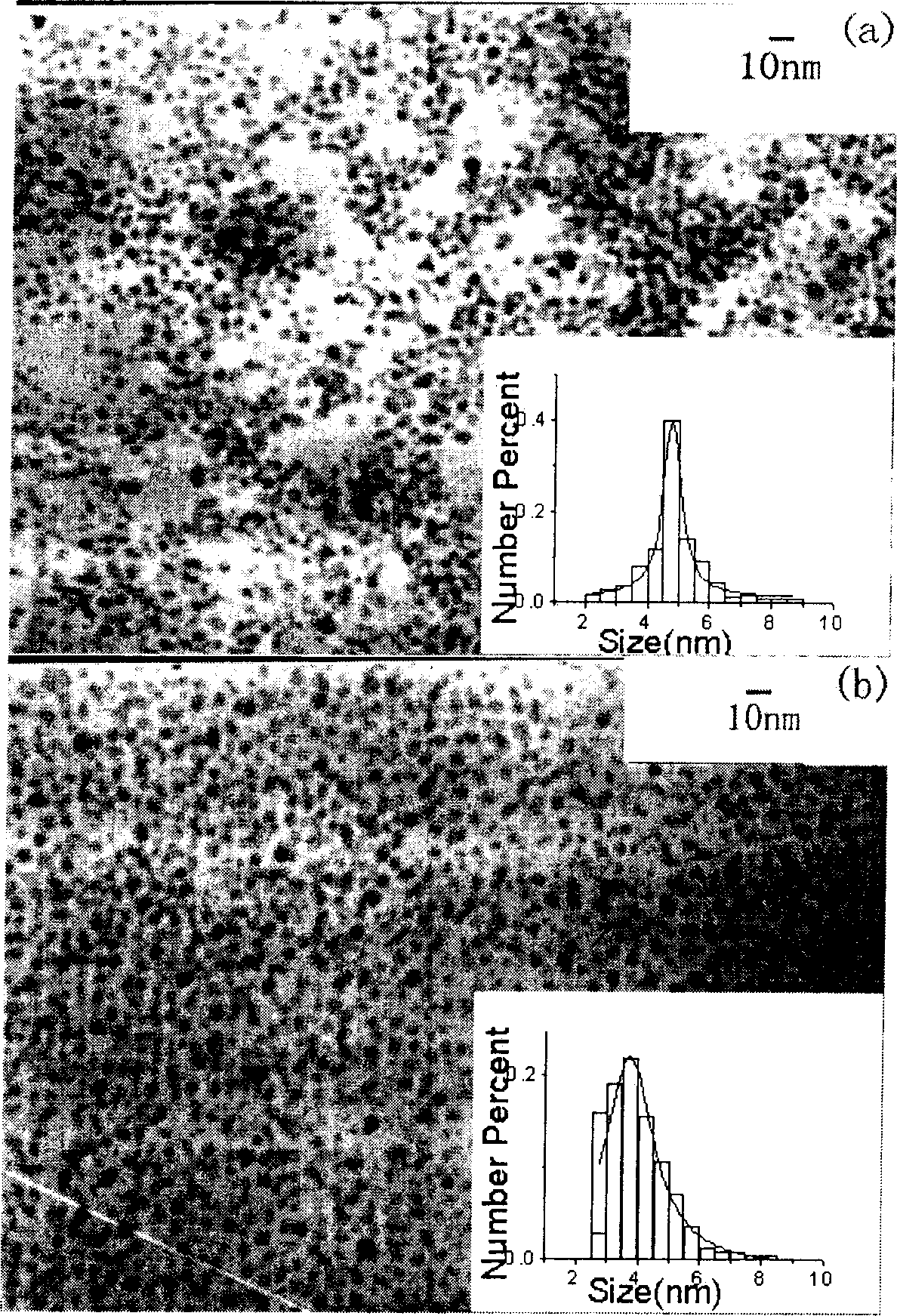

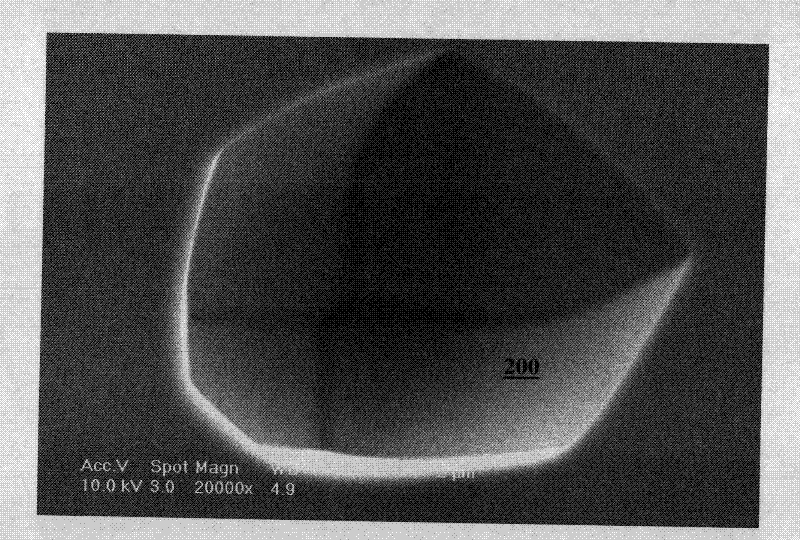

Supersonic liquid phase reduction process for preparing monodisperse nano germanium crystal

The present invention is the process of utilizing metal hydride to reduce germanium chloride to prepare near monodisperse nanometer germanium crystal under supersonic reaction condition. The present invention has high energy supersonic water bath to replace high temperature reaction environment to promote the formation of nanometer crystal and the dispersion in the solution, and adopts strongly reductive metal hydride as reductant for preparing near monodisperse nanometer germanium crystal under room temperature condition. Through experiments, the nanometer germanium crystal preparing conditions are optimized. Preparing monodisperse nanometer germanium crystal is significant in research of the relationship between the performance and the size of nanometer material and is valuable in the design and manufacture of semiconductor devices.

Owner:ZHEJIANG UNIV

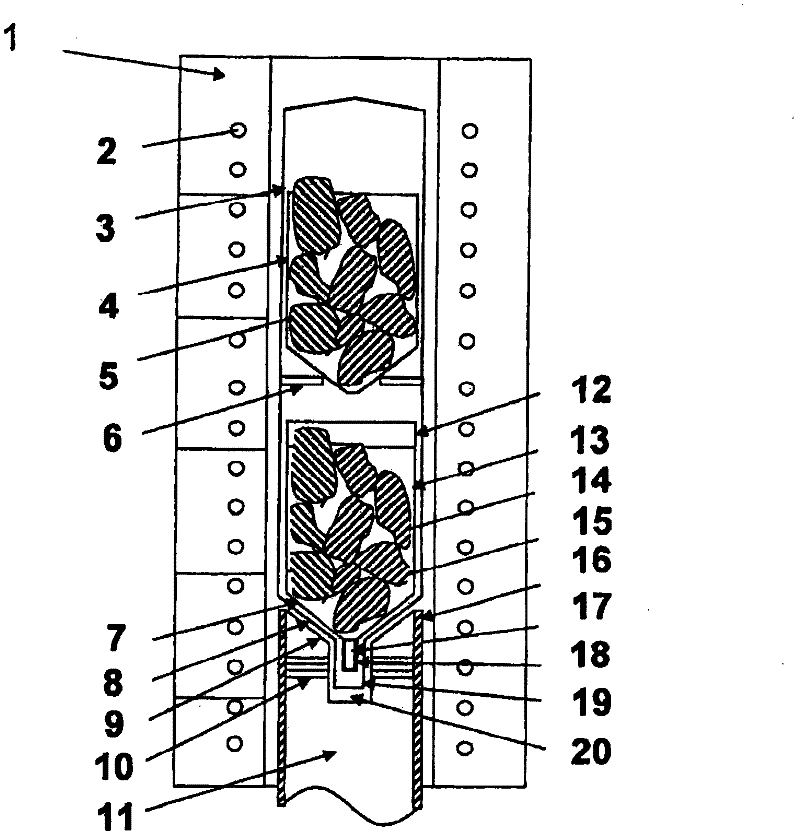

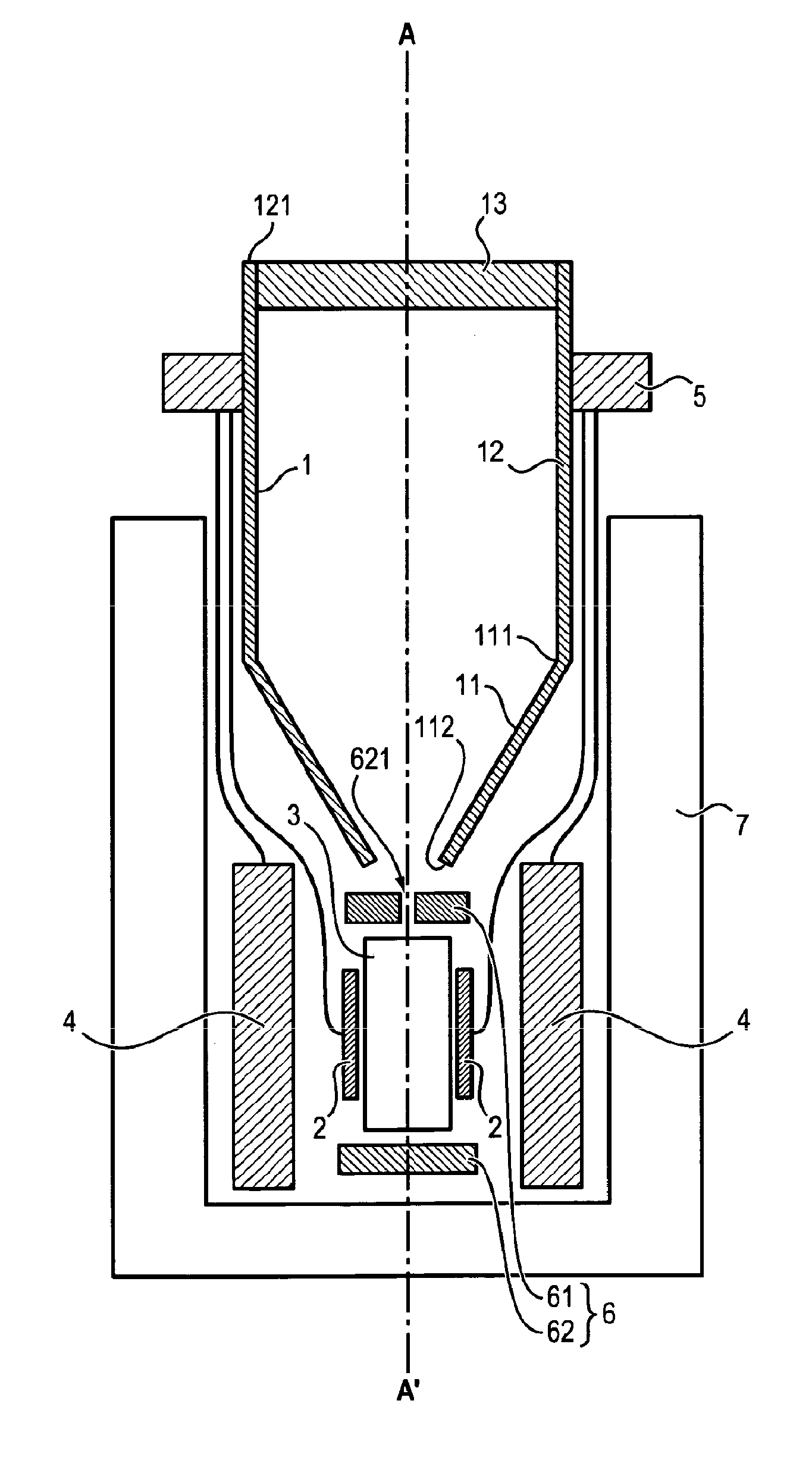

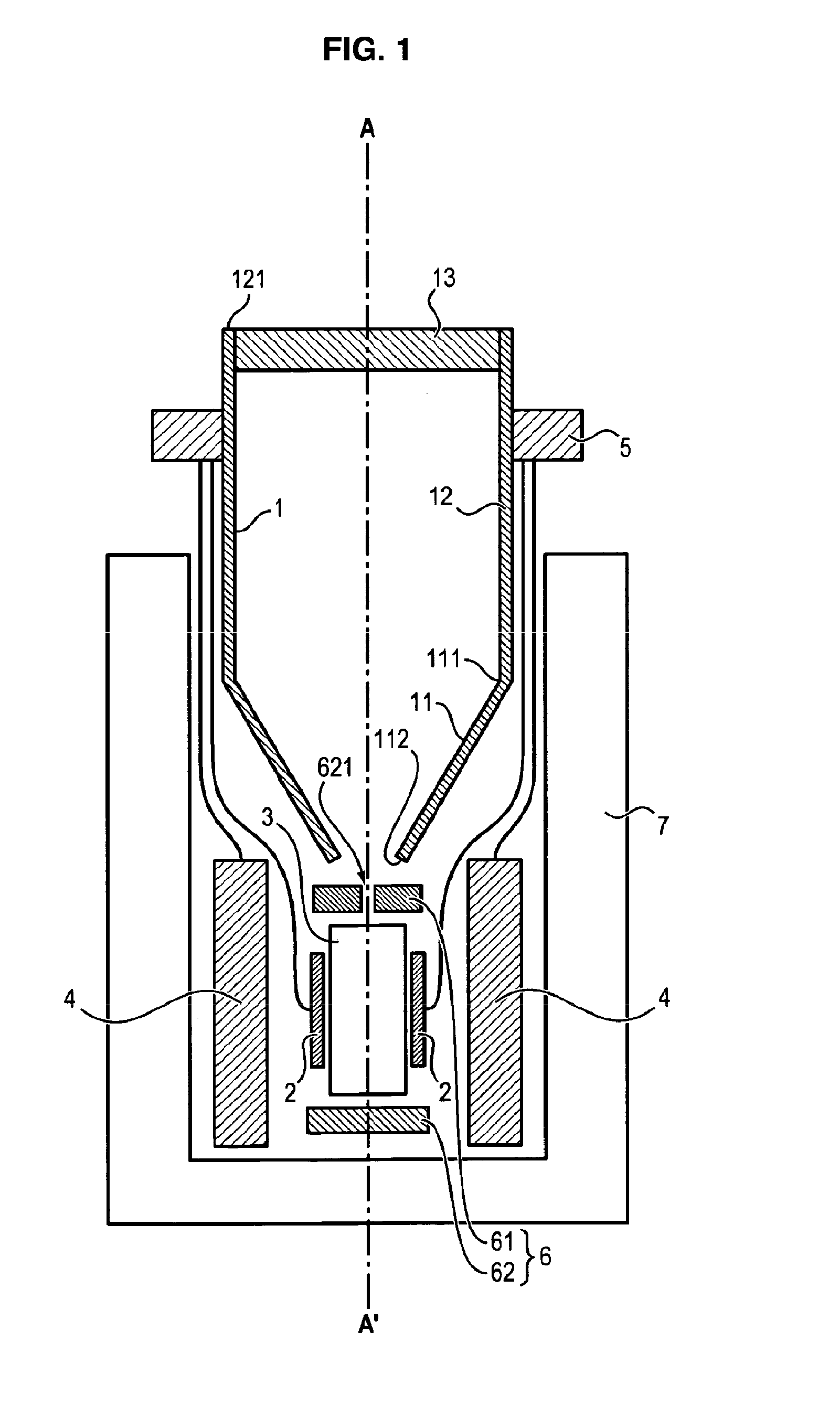

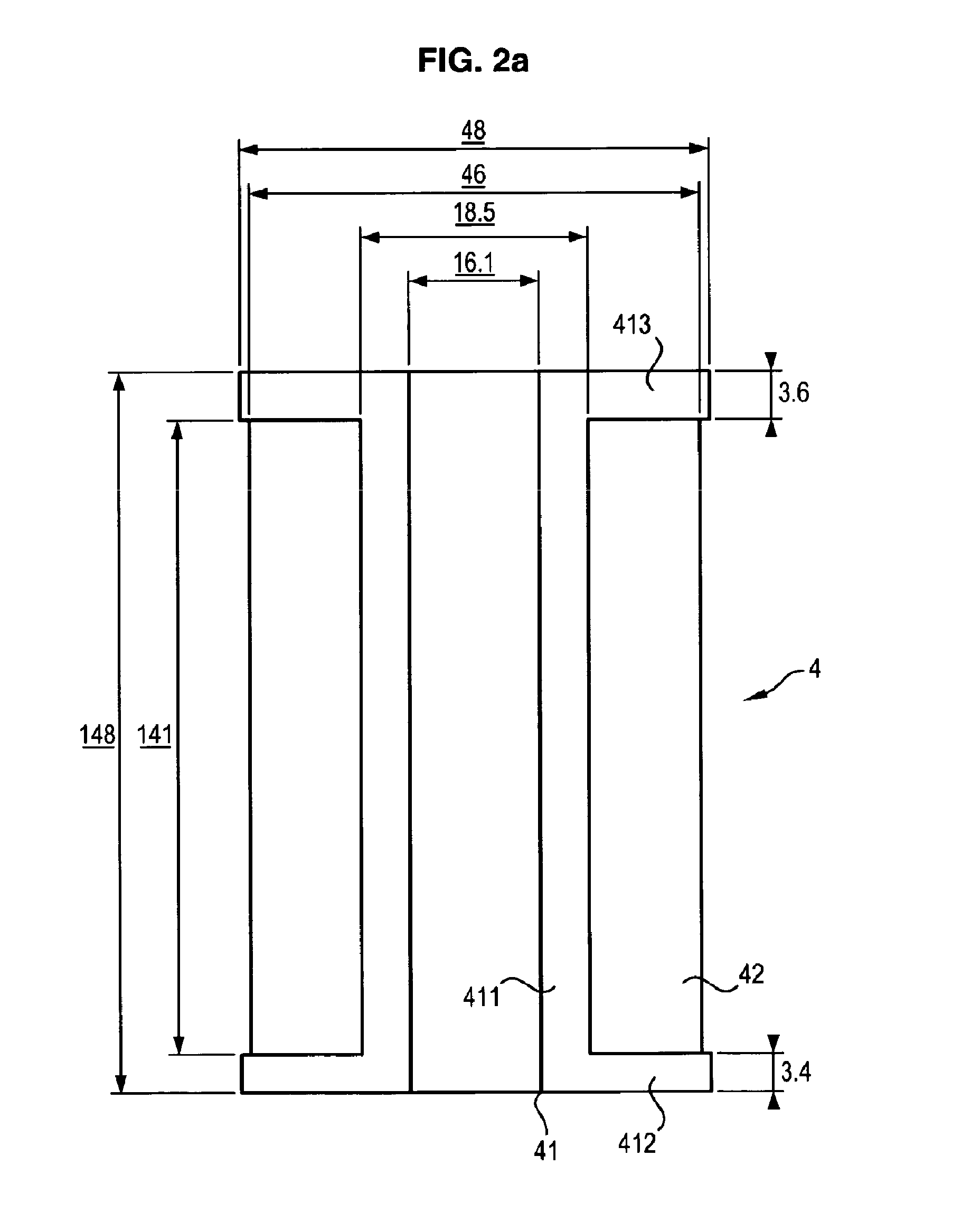

Laser device for emitting waves in the terahertz range

InactiveUS20140045700A1Laser using scattering effectsLaser optical resonator constructionSuperconducting CoilsAcoustics

A laser device for emitting waves in a frequency range belonging to the terahertz range, includes the following, in combination: a wave guide extending longitudinally along an axis A-A′; a superconducting coil arranged coaxially to the wave guide and arranged at a first end of the wave guide; a p-Ge p-doped germanium crystal arranged inside the coil such that the turns of the superconducting coil at least partially surround the p-Ge crystal; a cooling device containing a coolant, the superconducting coil and the p-Ge crystal being arranged in the cooling device, and the wave guide partially extending outside the cooling device; and removing the coolant from the wave guide.

Owner:UNIV DE MONTPELLIER +1

Method for adhering dirty materials in growth process of germanium crystals

ActiveCN111809237AEasy to gather and bondClosely arrangedPolycrystalline material growthBy pulling from meltPhysical chemistrySeed crystal

The invention relates to the technical field of semiconductor preparation, in particular to a method for adhering dirty materials in the growth process of germanium crystals, which comprises the following steps: calcining germanium materials; inserting seed crystals into an obtained germanium melt, setting the pulling speed of the first crystal after welding is stable, and carrying out seeding; starting and stopping the second crystal pulling speed in an inching mode, controlling the edge of the dirty material to be separated from the liquid level of the germanium melt, connecting the center area of the dirty material with the germanium melt, carrying out necking down growth, then adjusting the second crystal pulling speed to the first crystal pulling speed, carrying out shouldering, and carrying out crystal growing continuously; when the diameter of the crystal reaches a target diameter, adjusting the pulling speed of the first crystal to the pulling speed of the second crystal, and repeating the above operation until the dross on the surface of the germanium melt is completely stuck, so that the time for sticking out the dirty material is shortened, the weight of the stuck dirtymaterial is small, and the loss of the dirty material caused by processing and purification is greatly reduced.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD

Polishing solution for chemically mechanically polishing germanium crystal and application method

InactiveCN104449404AImprove efficiencyReduce roughnessSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesHardnessSurface-active agents

The invention relates to a polishing solution for chemically mechanically polishing germanium crystal and an application method. The polishing solution comprises a rough polishing solution and a fine polishing solution, wherein the rough polishing solution is mainly prepared from the following raw materials in percentage by weight: 10 to 50% of hydrosol grinding material, 0.2 to 1.5% of an oxidant, 0.5 to 2% of a pH conditioner, 0.2 to 1.5% of a chelating agent, and 0.1 to 1% of a surface active agent, wherein the hydrosol grinding material is 15 to 110nm in particle size and has the concentration being not less than 40wt% (percentage by weight) and hardness being not greater than 7 Mohs; the fine polishing solution is mainly prepared from 0.1 to 0.5% of a surface active agent, and the balance of deionized water. The two-step polishing method is performed for chemical mechanical polishing and comprises two steps of selecting the rough polishing solution and then second the fine polishing solution; the two polishing can be performed through one polishing machine. The polishing solution has the beneficial effect that the problems of low rate, high roughness and pollution of metal ions and particles in chemical mechanical polishing of germanium crystal materials can be solved.

Owner:HEBEI UNIV OF TECH

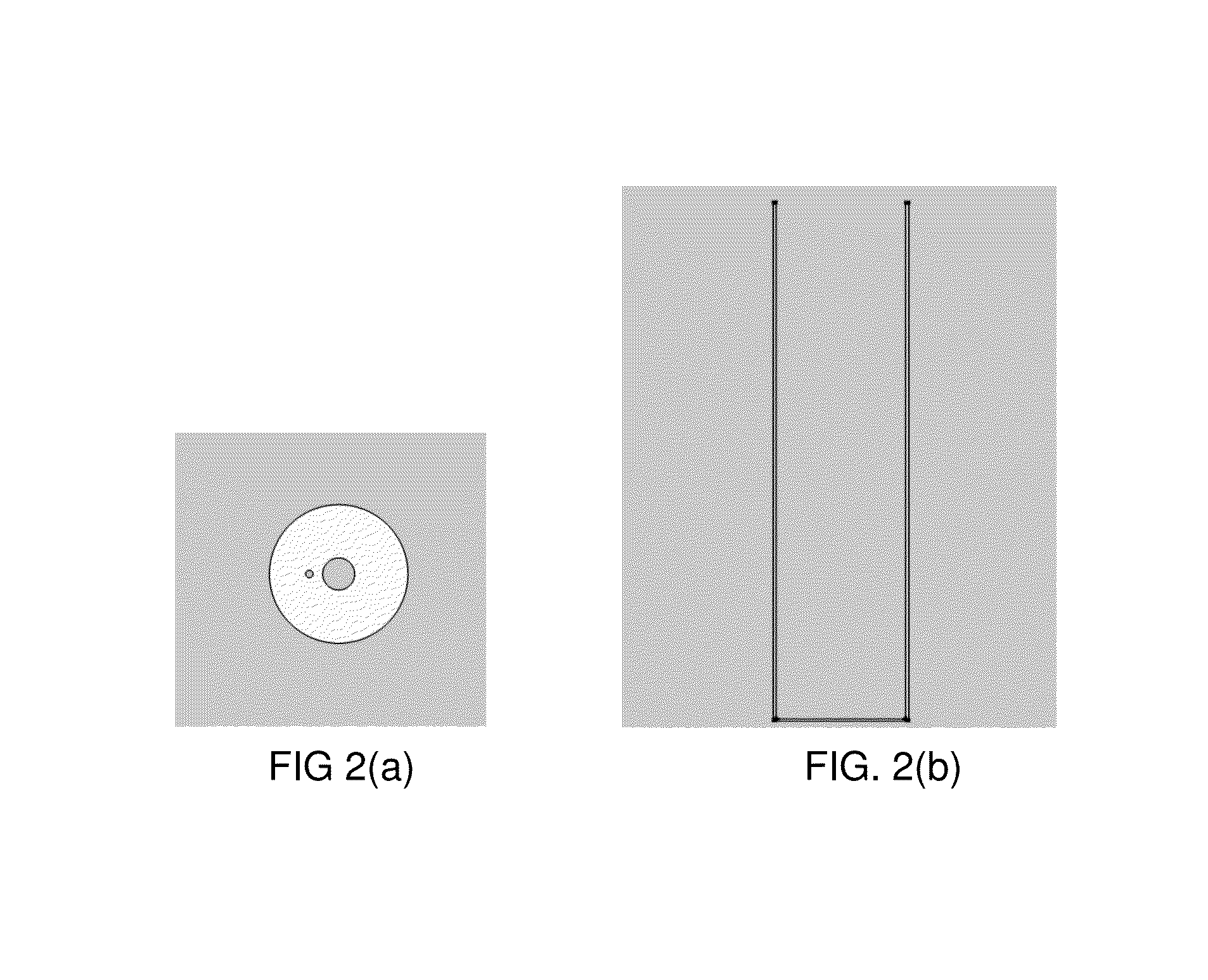

Handheld isotope identification system

InactiveUS20050133726A1Radiation pyrometryMaterial analysis using wave/particle radiationNitrogenIsotope

A portable radiation detector using a high-purity germanium crystal as the sensing device. The crystal is fabricated such that it exhibits a length to width ratio greater than 1:1 and is oriented within the detector to receive radiation along the width of said crystal. The crystal is located within a container pressurized with ultra-pure nitrogen, and the container is located within a cryostat under vacuum.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Method for removing fluorine from germanium-containing material

The invention provides a method for removing fluorine from a germanium-containing material. The germanium-containing material is calcined under the microwave condition and is subjected to air pumping.The germanium-containing material is calcined by microwave, the inside and the outside of the germanium-containing material are heated simultaneously by microwave, so that the inside and the outsideof the germanium-containing material are heated uniformly and transformation of germanium crystal form is avoided; meanwhile, fluorine elements distributed in the germanium-containing material are decomposed and volatized uniformly, and the fluorine content of the germanium-containing material after calcination is reduced to be below 0.5 percent.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

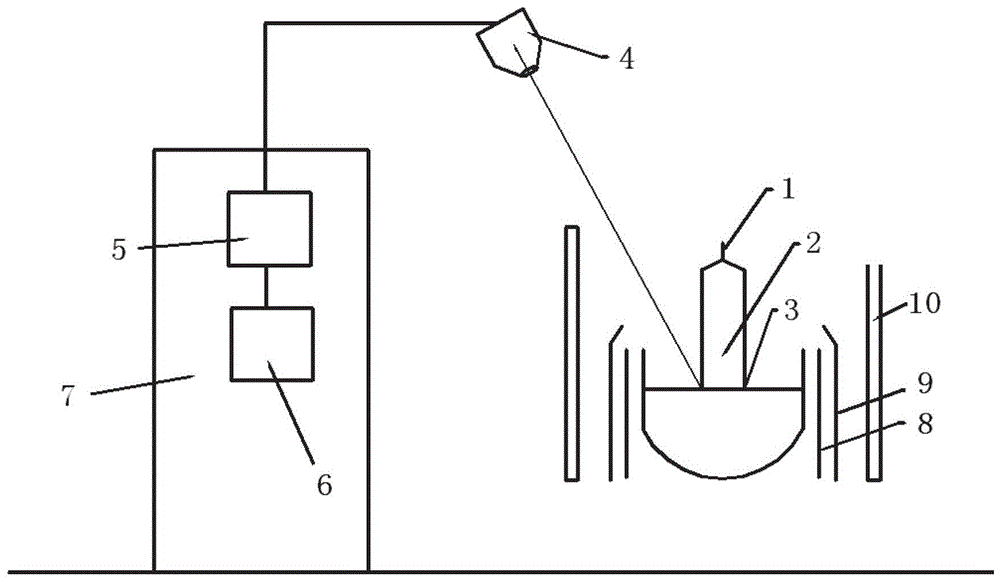

Czochralski germanium single crystal diameter measurement and control system

InactiveCN102912429BReduce labor intensityReduce transfer volumeBy pulling from meltAutomatic controlSingle crystal

Owner:YUNNAN KIRO CH PHOTONICS

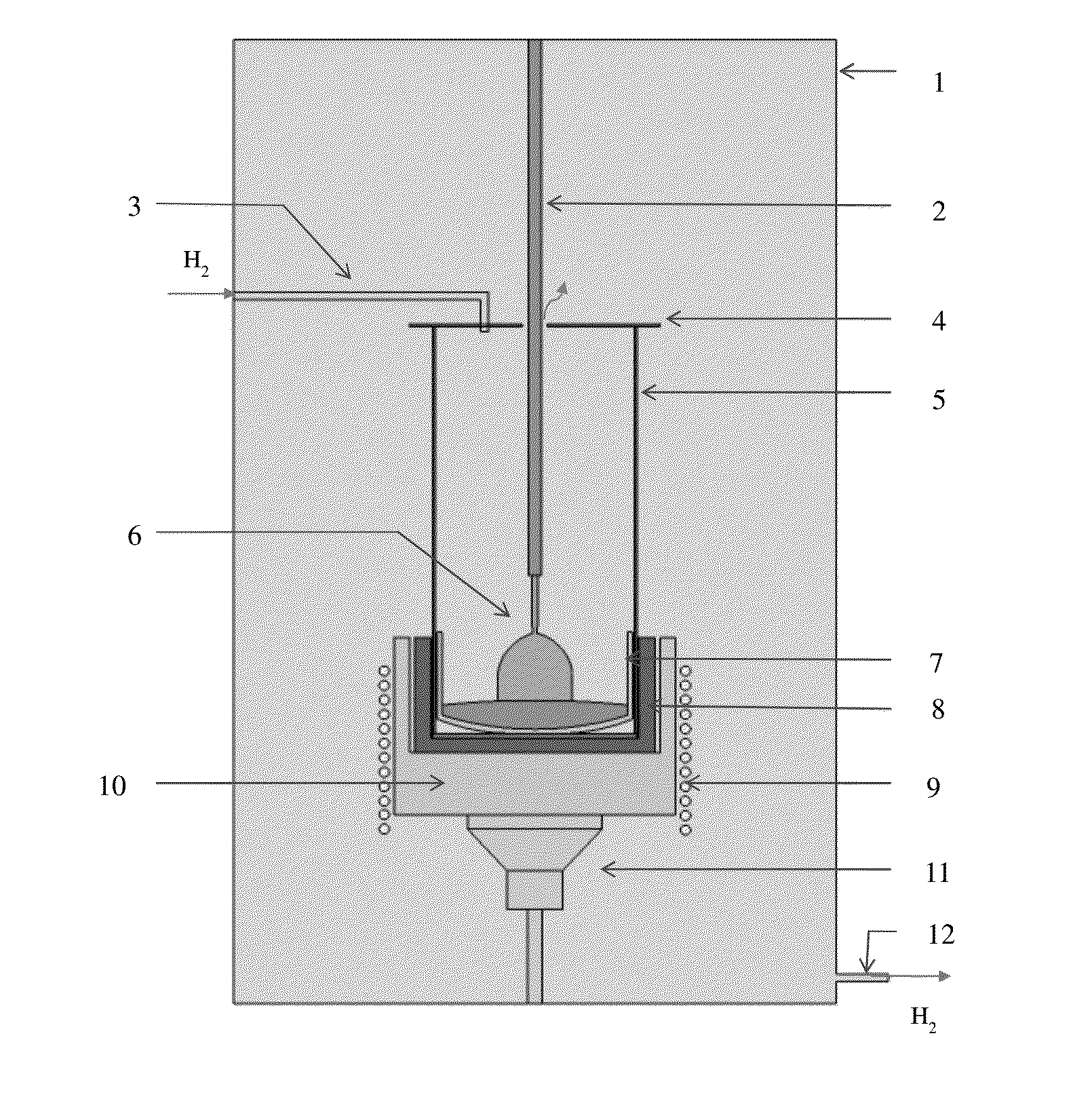

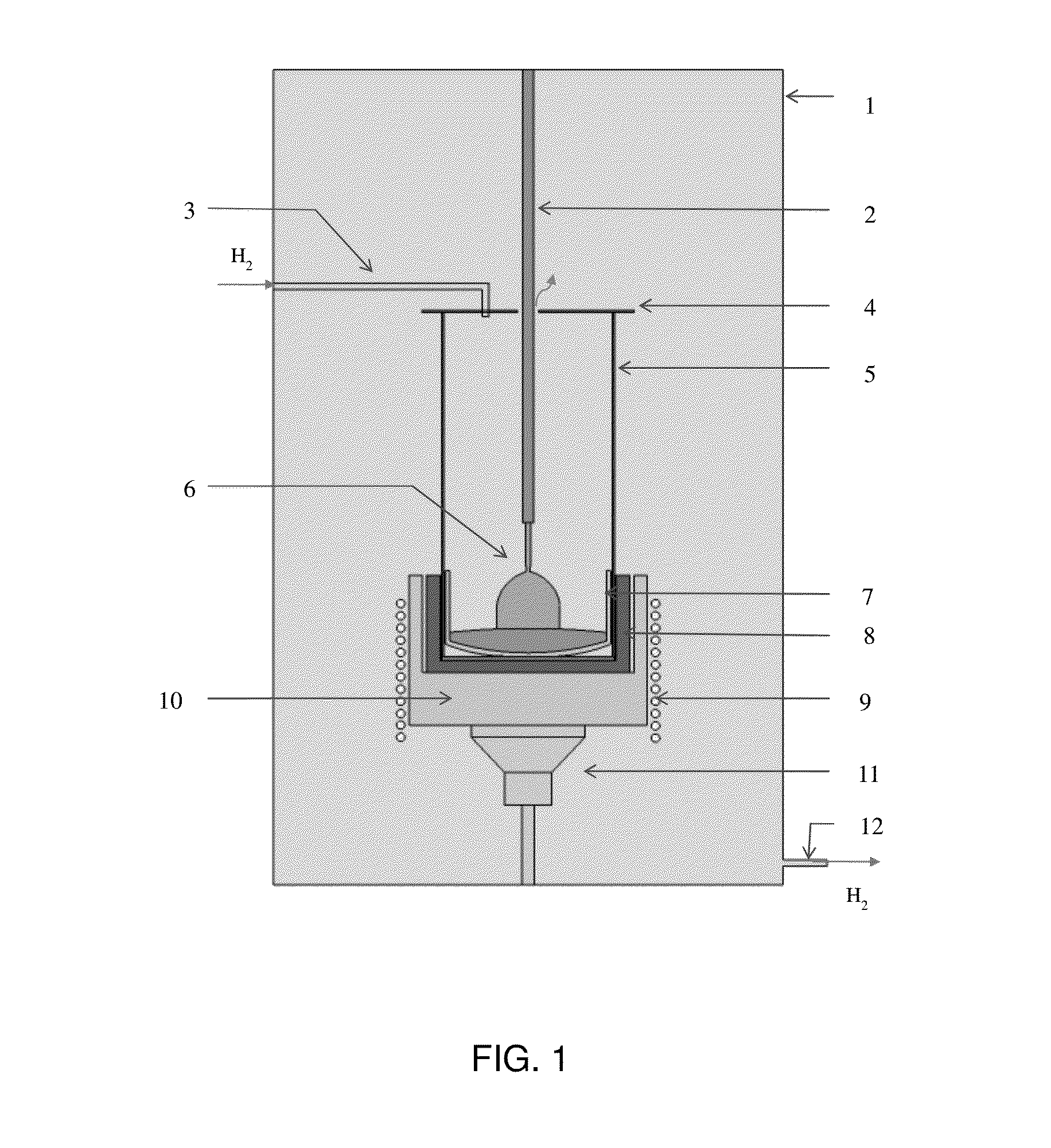

Method of Growing Germanium Crystals

ActiveUS20160153117A1Avoid pollutionHigh operating requirementsPolycrystalline material growthBy pulling from meltAutomatic controlLoad cell

In accordance with the present invention, taught is a high purity germanium crystal growth method utilizing a quartz shield inside a steel furnace. The quartz shield is adapted for not only guiding the flow of an inert gas but also preventing the germanium melt from contamination by insulation materials, graphite crucible, induction coil and stainless steel chamber. A load cell provides automatic control of crystal diameter and helps to ensure exhaustion of the germanium melt. The method is both convenient and effective at producing high purity germanium crystals by relatively low skilled operators.

Owner:SOUTH DAKOTA BOARD OF REGENTS

Germanium ingots/wafers having low micro-pit density (mpd) as well as systems and methods for manufacturing same

ActiveCN102356186APolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleVolumetric Mass Density

Systems and methods are disclosed for crystal growth including features of reducing micropit cavity density in grown germanium crystals. In one exemplary implementation, there is provided a method of inserting an ampoule with raw material into a furnace having a heating source, growing a crystal using a vertical growth process wherein movement of a crystallizing temperature gradient relative to the raw material / crucible is achieved to melt the raw material, and growing, at a predetermined crystal growth length, the material to achieve a monocrystalline crystal, wherein monocrystalline ingots having reduced micro-pit densities are reproducibly provided.

Owner:AXT INC +1

Polishing solution for germanium crystal and preparation method thereof

InactiveCN113583573ANo pollution in the processReduce roughnessPolishing compositions with abrasivesWaferingOrganic solvent

The invention provides a polishing solution for germanium crystals. The polishing solution is mainly prepared from the following raw materials in percentage by weight: 20-80% of a polishing agent; 10%-50% of an organic solvent; 1%-30% of a pH value regulator; and the balance of deionized water. The invention also provides a preparation method of the polishing solution for the germanium crystal. The preparation method comprises the following steps: step 1, adding deionized water into the polishing agent, and adding an organic solvent under a stirring condition; and 2, adding the pH additive into the solution obtained in the step 1, and uniformly stirring to obtain the polishing solution. The polishing solution for the germanium crystal does not contain an oxidizing agent, does not contain heavy metal ions and has no pollution to the environment. The polished wafer has low roughness and is not easy to scratch, and the chemical reagent of the polishing solution is simple and is an ideal polishing solution material.

Owner:安徽光智科技有限公司

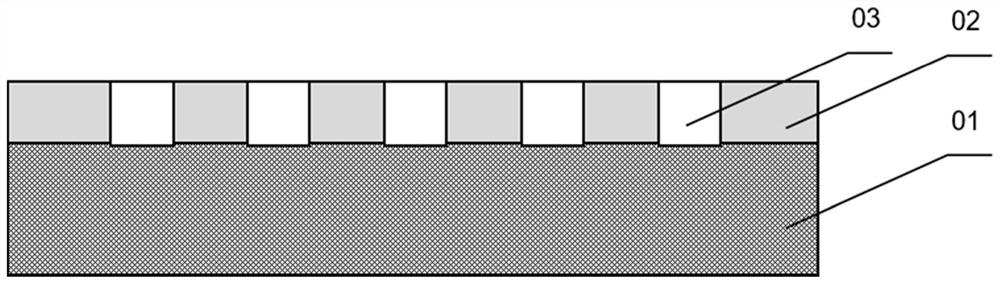

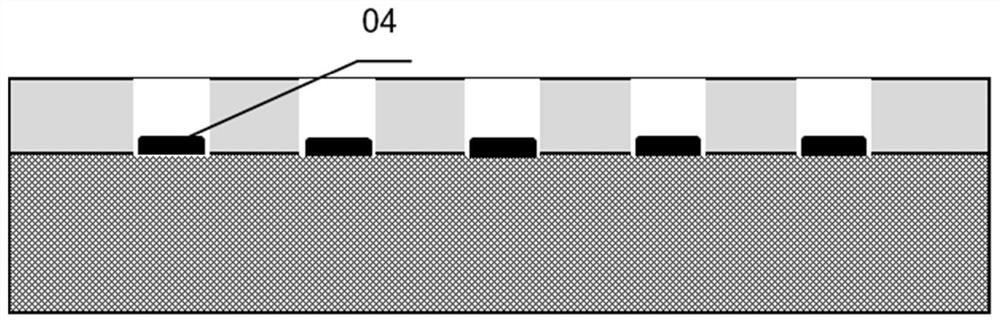

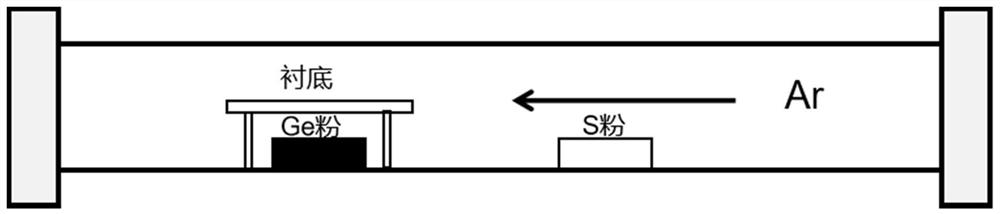

Preparation method for growing germanium sulfide single crystal film on SiO2 substrate

PendingCN113972299AEasy to integrateLow growth temperatureFinal product manufactureSemiconductor/solid-state device manufacturingSingle crystalSulfide

The invention discloses a preparation method for growing a germanium sulfide single crystal film on a SiO2 substrate. The method comprises the following steps: cleaning the surface of the substrate by using acetone, ethanol and deionized water, wherein the substrate material is a Si / SiO2 substrate or a SiO2 glass substrate; carrying out photoetching on the substrate, spin-coating photoresist, and after photoetching is carried out, obtaining a groove pattern through dry etching or wet etching; depositing a layer of germanium crystal in the groove pattern of the substrate to obtain a processed substrate; and placing the processed substrate in chemical vapor deposition equipment for growth, taking high-purity sulfur powder and high-purity germanium powder as growth sources, and then preparing the germanium sulfide single crystal thin film on the SiO2 substrate. The preparation method provided by the invention is simple to operate, the monocrystal germanium sulfide GeS2 can be grown on the SiO2 substrate, and the monocrystal germanium sulfide crystal is high in quality and small in surface roughness and has a forbidden band width corresponding to blue-violet light of a visible light band.

Owner:SOUTH CHINA UNIV OF TECH

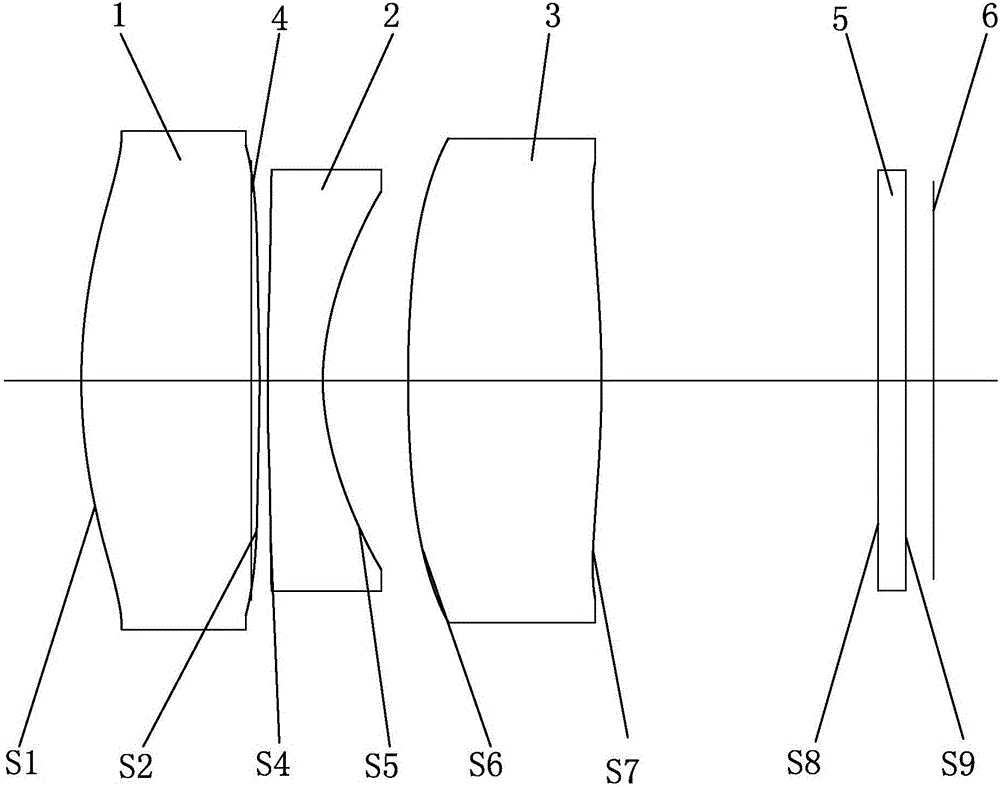

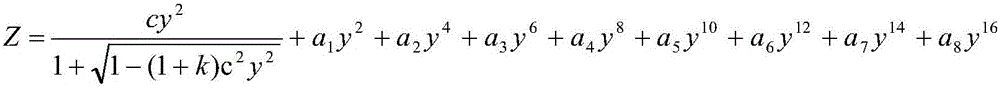

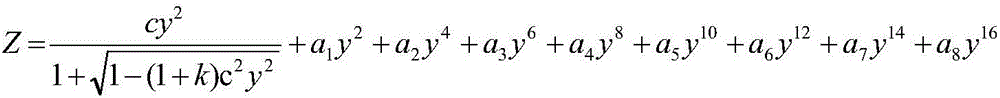

Optical athermalization, high-pixel, high-illumination and low-cost heat imaging system

InactiveCN106842524AReduce processing costsThe resolution is stable and not out of focusOptical elementsCamera lensChalcogenide glass

The invention discloses an optical athermalization, high-pixel, high-illumination and low-cost heat imaging system. The optical athermalization, high-pixel, high-illumination and low-cost heat imaging system is sequentially provided with a first lens, a diaphragm, a second lens, a third lens and a light sensing chip from an object side to an image side, wherein the first lens, the second lens and the third lens are chalcogenide glass non-spherical surface lenses; focal distances of the first lens and the third lens are positive; and the focal distance of the second lens is negative. According to the optical athermalization, high-pixel, high-illumination and low-cost heat imaging system, low-price chalcogenide glass is adopted and the material can be molded by die pressing, so that the processing cost can be reduced; the thermal refractive index coefficient of the chalcogenide glass is only 1 / 10 of a germanium crystal material, so that the change of the resolving power of a system composed of the chalcogenide glass lenses along with temperature is relatively small, and stable resolving power and no focus shift can be realized through optical athermalization; and meanwhile, the complexity of the structure is reduced and the cost is reduced. The lens is designed by adopting wide spectrums with the lengths of 7.5 microns to 14 microns at the ratio of 1 to 1 to 1 to 1, and has extremely good image sharpness at a far-infrared band; and a whole picture can be clearly imaged.

Owner:UNION OPTECH

Polishing liquid for germanium crystal chemical and mechanical polishing and use method thereof

InactiveCN109777303AImprove efficiencyReduce roughnessPolishing compositions with abrasivesLow speedCompound (substance)

The invention relates to polishing liquid for germanium crystal chemical and mechanical polishing and a use method thereof. The polishing liquid comprises coarse polishing liquid and fine polishing liquid, wherein the coarse polishing liquid is mainly prepared from the following raw materials in percentage by weight: 10 to 50 percent of SiO2 hydrosol abrasive grinding materials with the grinding material particle diameter being 15 to 110nm, the concentration being higher than or equal to 40 weight percent and the hardness being smaller than or equal to 7Mohs, 0.2 to 1.5 percent of oxidizing agents, 0.5 to 2 percent of pH regulating agents, 0.2 to 1.5 percent of chelating agents and 0.1 to 1 percent of surfactants; the fine polishing liquid is mainly prepared from 0.1 to 0.5 percent of surfactants and the balance deionized water. A two-step polishing method is used for chemical mechanical polishing; coarse polishing liquid is selected in the first step; the fine polishing liquid is selected in the second step; the two steps of polishing are completed on the same polishing machine. The polishing liquid has the beneficial effects that the problems of low speed, high roughness, metal ion and particle staining and the like of the germanium crystal materials in the chemical and mechanical polishing process can be solved.

Owner:青岛凯玉盈商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com